Polycrystalline diamond compact and synthetic method thereof

A technology of diamond composite sheet and polycrystalline diamond, which is used in earth-moving drilling, drilling equipment, drill bits, etc., can solve the problems of increasing the depth of decobalt, failure, etc., to improve the quality of decobalt, increase the depth, improve performance and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

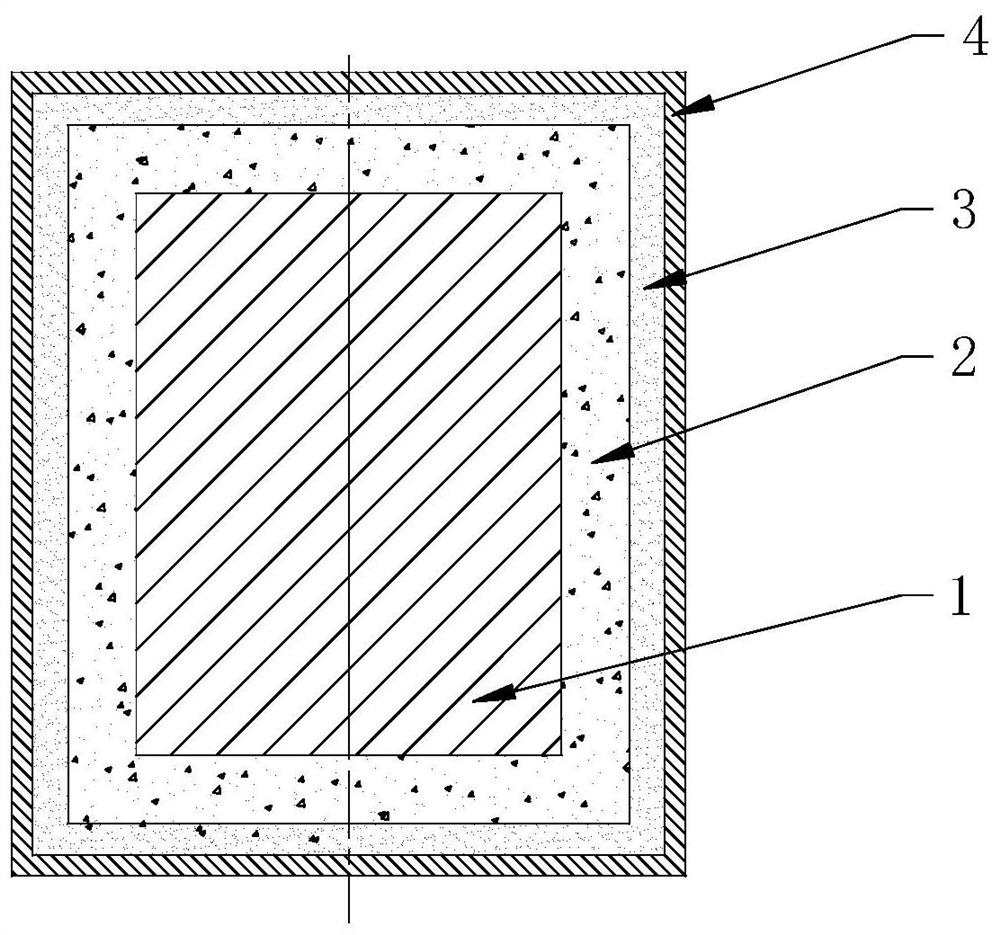

[0029] A method for synthesizing a polycrystalline diamond compact, characterized in that: the method for synthesizing the polycrystalline diamond compact comprises:

[0030] 1. Mix diamond particles with a particle size of 1-2 and 10-20 μm in a ratio of 2:8 with metal catalyst cobalt with a particle size of 1-3 μm in a ratio of 95:5;

[0031] 2. Coat the mixture of the previous step on the outer surface of the cylindrical cemented carbide core, wherein the diameter of the cemented carbide core is 12 mm, the height is 9 mm, and the thickness of the coated diamond particles is 2 mm;

[0032] 3. Put the above materials into a high-temperature and high-pressure container, and sinter at 5-9GPa and 1400-1800°C for 10 minutes.

[0033] 4. Using electric discharge machining, the sintered diamond composite sheet is processed into a diamond composite sheet with a diameter of 15.88mm and a height of 13.2mm;

[0034] 5. Immerse the processed diamond composite sheet in aqua regia at a te...

Embodiment 2

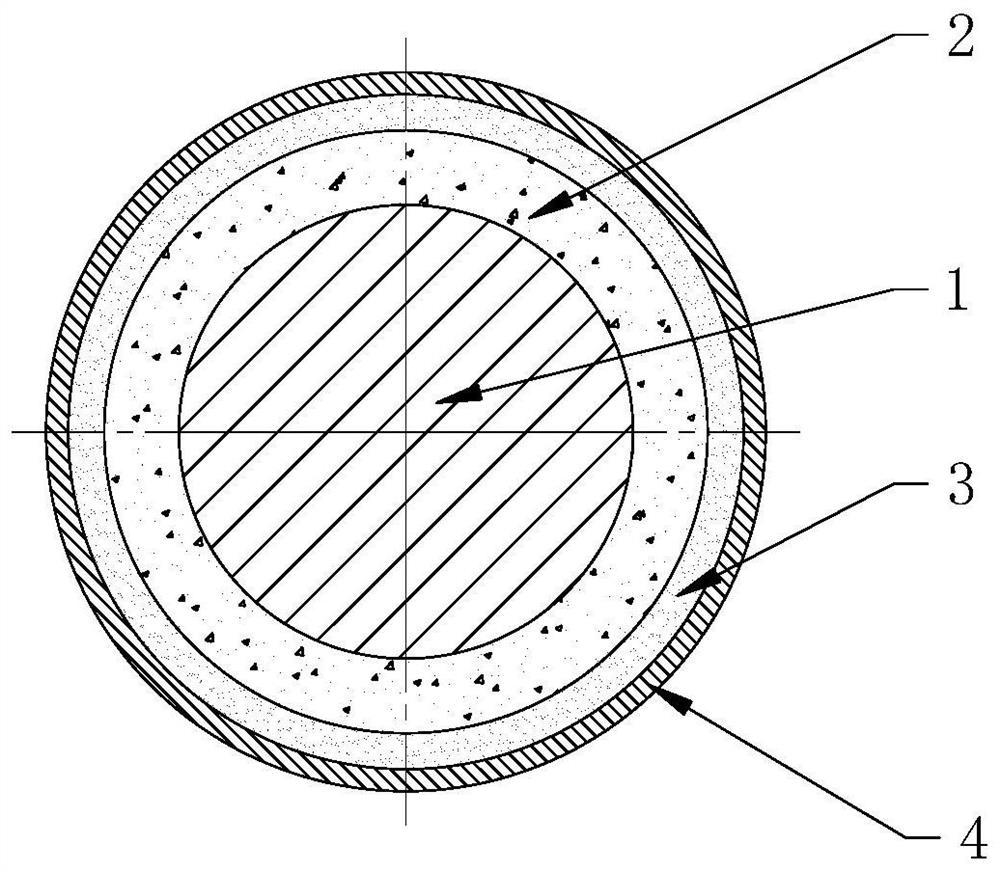

[0038] A method for synthesizing a polycrystalline diamond compact, characterized in that: the method for synthesizing the polycrystalline diamond compact comprises:

[0039] 1. Mix two kinds of diamond powder with a particle size of 3-6μm and 20-30um in a ratio of 2:8 with metal catalyst cobalt with a particle size of 1-3μm in a ratio of 95:5;

[0040] 2. Coat the mixture of the previous step on the outer surface of the cylindrical cemented carbide core, wherein the diameter of the cemented carbide core is 10.9 mm, the height is 8 mm, and the thickness of the coated diamond particles is 2.5 mm;

[0041] 3. Put the above materials into a high-temperature and high-pressure container, and sinter at 5-9GPa and 1400-1800°C for 10 minutes;

[0042] 4. The polycrystalline diamond composite sheet synthesized by the above method is processed into a cylinder with a diameter of 15.88mm and a height of 13.2mm by a grinder;

[0043] 5. Immerse the processed diamond composite sheet in aqu...

Embodiment 3

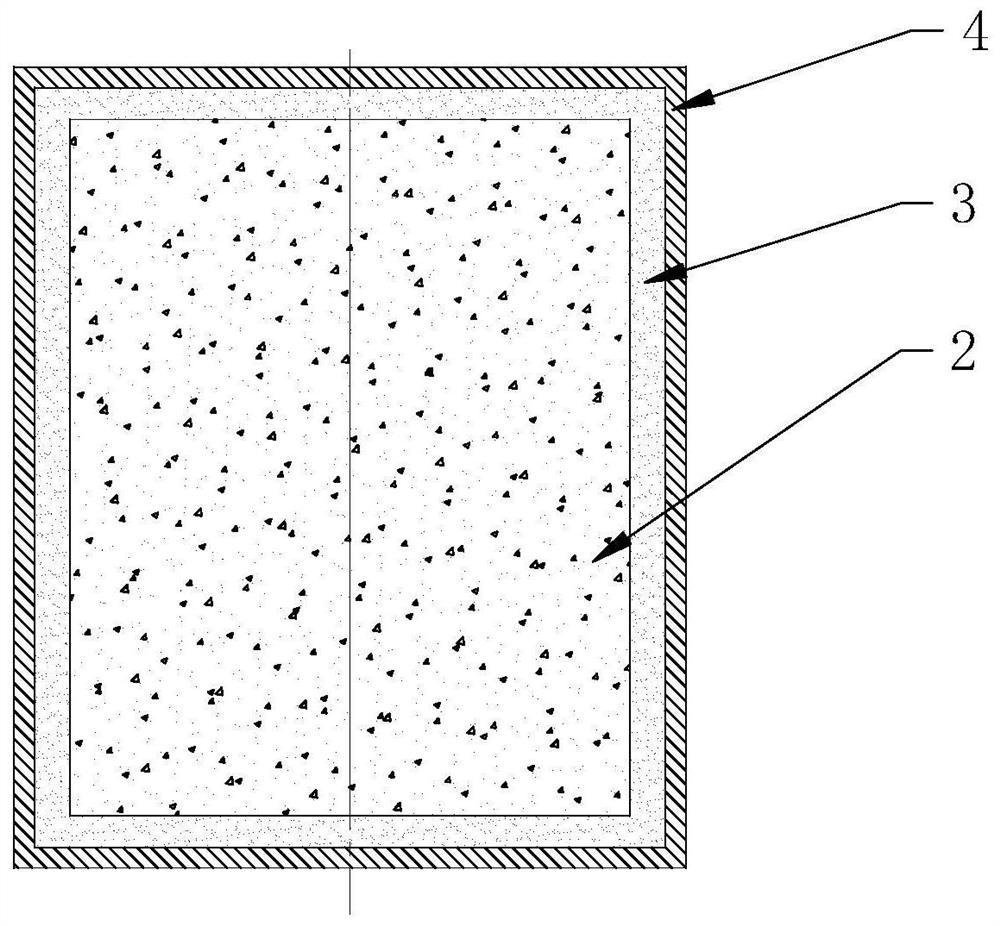

[0047] A method for synthesizing a polycrystalline diamond compact, characterized in that: the method for synthesizing the polycrystalline diamond compact comprises:

[0048]1. Mix two kinds of diamond powder with a particle size of 3-6μm and 20-30um in a ratio of 2:8 with metal catalyst cobalt with a particle size of 1-3μm in a ratio of 95:5;

[0049] 2. Make the above mixture into a cylinder with a diameter of 16.5mm and a height of 15mm;

[0050] 3. Put the above materials into a high-temperature and high-pressure container, and sinter at 5-9GPa and 1400-1800°C for 10 minutes;

[0051] 4. The polycrystalline diamond composite sheet synthesized by the above method is processed into a cylinder with a diameter of 13.44mm and a height of 8.1mm by laser equipment;

[0052] 5. Immerse the processed diamond composite sheet in aqua regia at a temperature of 80°C for 7-40 days to remove metal cobalt and WC in the polycrystalline diamond layer;

[0053] 6. By means of chemical depo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com