Plant-based treatment method for heavy metal sewage

A heavy metal and sewage technology, applied in the field of phytoremediation, can solve problems such as hindering the restoration of heavy metal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

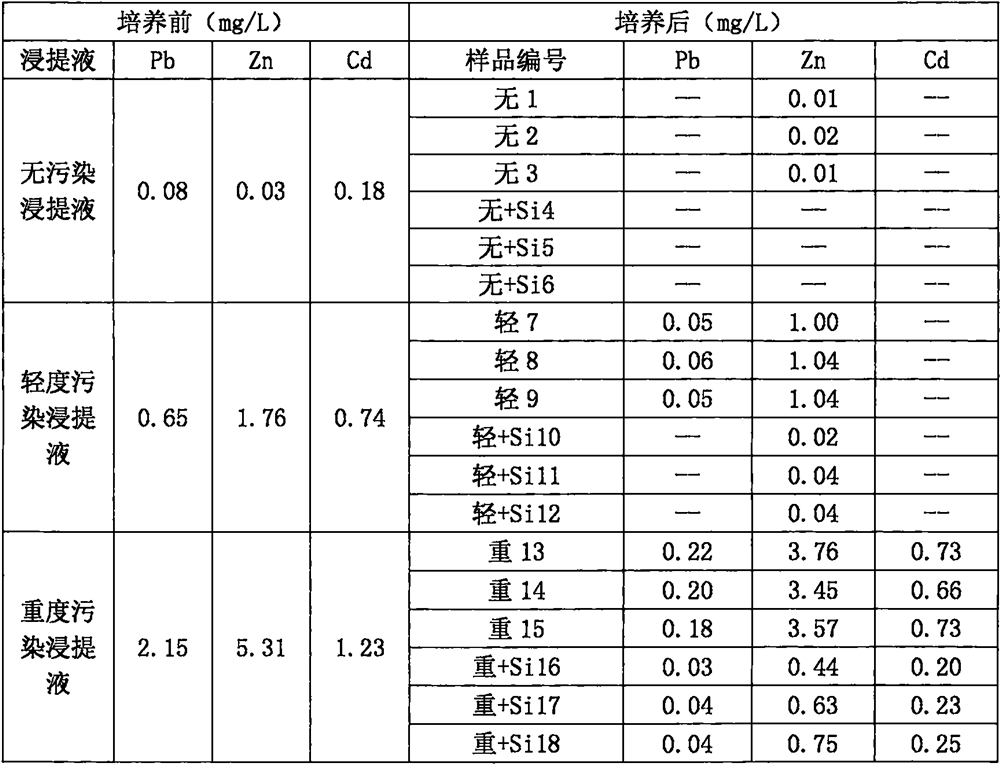

Embodiment 1

[0018] A plant treatment method for heavy metal sewage, comprising the following steps:

[0019] (1) Preparation of lead-zinc ore leach solution slightly polluted by heavy metals

[0020] Weigh 10kg of heavy metal-contaminated lead-zinc ore soil samples crushed in advance and sieved through a 10-mesh sieve under a sterile environment, mix with 10L deionized water and stir for 0.5h, shake with an oscillator for 2h, and let stand for 0.5h , filter the supernatant with analytical filter paper to obtain 6L of extract solution with a water-to-soil ratio of 1:1.

[0021] (2) Add sodium silicate

[0022] Divide 6L of the extraction solution into two equal parts, one of which is added with sodium silicate to control the silicon concentration of 1mM, and each part of the extraction solution is equally divided into three culture pots.

[0023] (3) Cultivation of white crane taro

[0024] Select 6 strains of white crane lily that have been diluted and pre-cultured with nutrient soluti...

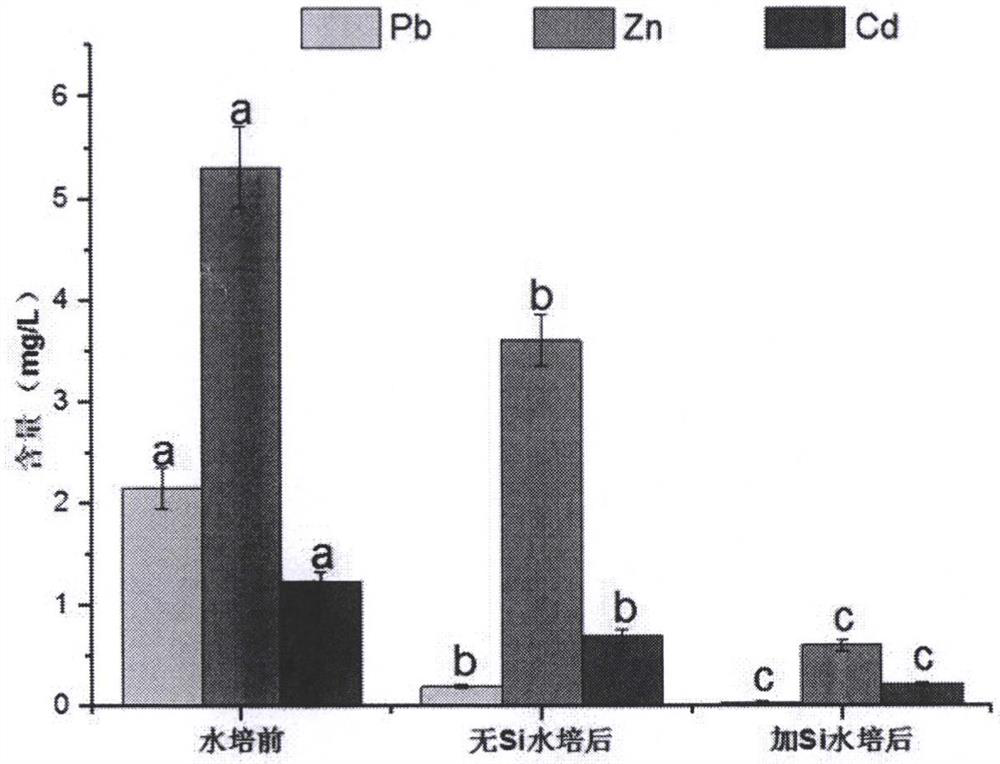

Embodiment 2

[0026] A kind of plant treatment method of heavy metal sewage, different from embodiment 1, comprises the following steps:

[0027] (1) Preparation of lead-zinc ore heavy metal heavily polluted soil sample leach solution

[0028] Weigh 10kg of heavy metal-contaminated lead-zinc ore soil samples crushed in advance and sieved with a 10-mesh sieve in a sterile environment, mix with 10L deionized water and stir for 0.5h, shake with an oscillator for 2h, and let stand for 0.5h. Filter the supernatant with analytical filter paper to obtain 6 L of extract solution with a water-to-soil ratio of 1:1.

[0029] (2) Add sodium silicate

[0030] Divide 6L of the extraction solution into two equal parts, one of which is added with sodium silicate to control the silicon concentration of 1mM, and each part of the extraction solution is equally divided into three culture pots.

[0031] (3) Cultivation of white crane taro

[0032] Select 6 strains of white crane lily that have been diluted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com