Shale gas fracturing flow-back fluid up-to-standard discharge treatment process method and system

A fracturing flowback fluid and treatment process technology, applied in mining wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as reducing water quality changes, instability, and inaccurate dosage of pretreatment chemicals. , to achieve the effect of accurate dosing, reducing turbidity and reducing the risk of inorganic scale fouling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is further described in detail. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention, that is, the described embodiments are only some of the embodiments of the present invention, but not all of the embodiments.

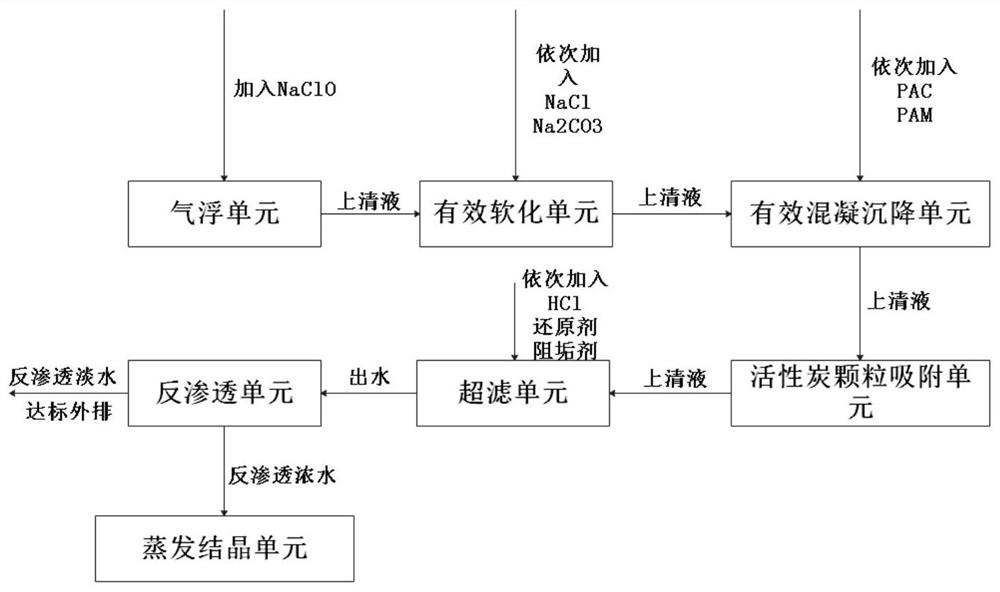

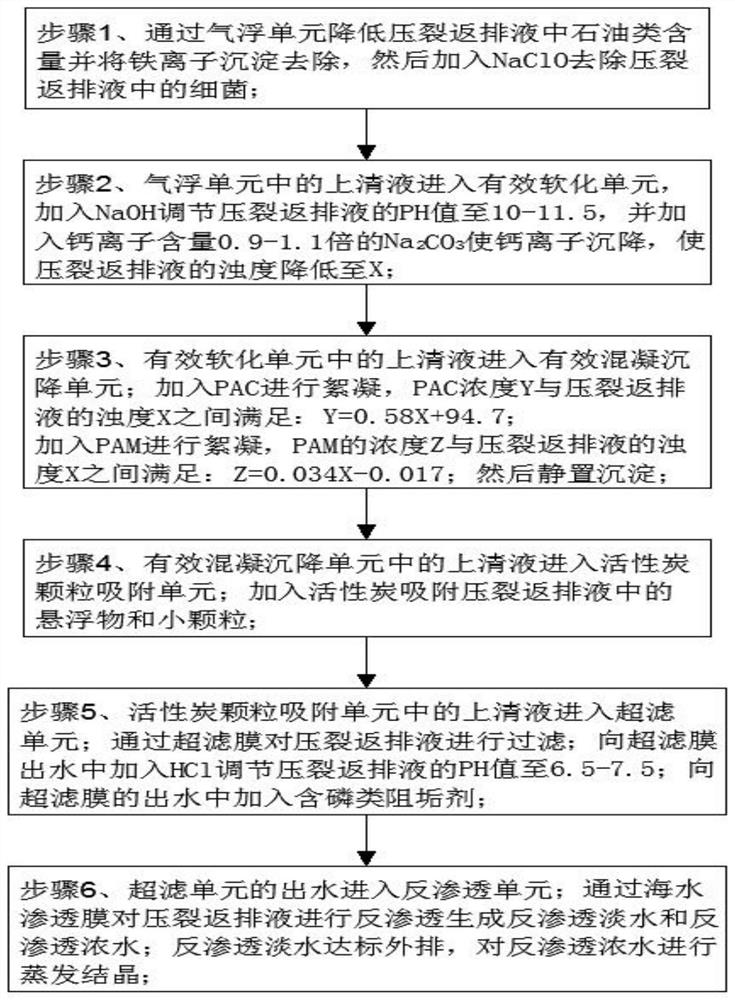

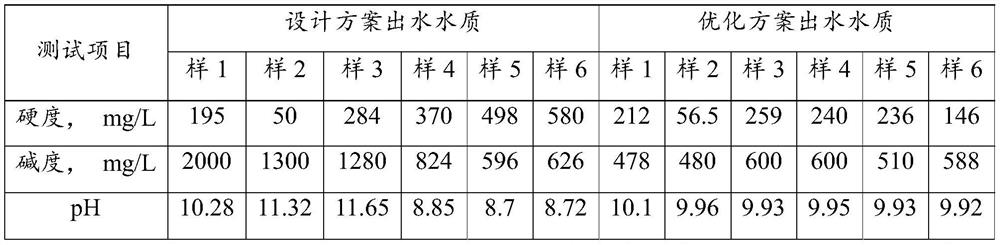

[0041] The present invention aims at the deficiencies of the existing shale gas fracturing flowback fluid up-to-standard discharge treatment technology, especially the deficiencies of the pretreatment technology, such as inaccurate dosing of fracturing flowback fluid pretreatment agents with different water qualities, resulting in The turbidity and scale-forming ions (calcium, magnesium, barium, strontium, carbonate) of the shale gas fracturing flowback fluid that cannot stably and effectively reduce water quality changes, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com