Anti-pollution device for hard-chromium plating processing during micro-arc oxidation treatment

A technology of micro-arc oxidation and hard chrome plating, applied in anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problem of poor adhesion of ions, inability to mix hard chromium plating solution, uneven and weak coating, etc. problems, to achieve uniform and firm coating, to avoid polluting the surrounding environment, and to increase the efficiency of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

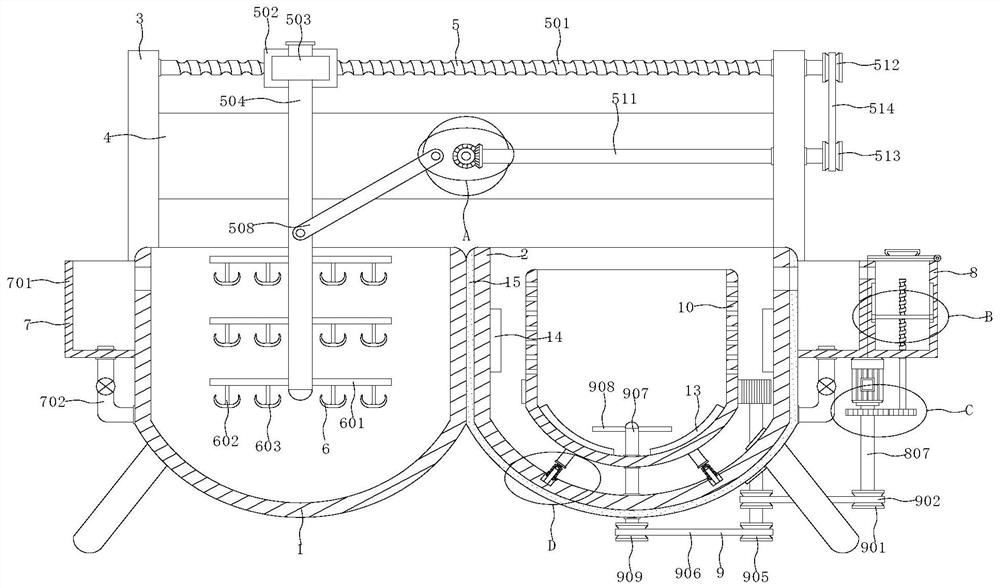

[0028] see Figure 1-8, the present invention provides a kind of technical scheme: a kind of anti-pollution device used for hard chrome plating processing during micro-arc oxidation treatment, comprising plating solution tank 2, the outer wall fixed sleeve of plating solution tank 2 is provided with insulation layer 15, the insulation layer 15 The outer wall of the other side is fixedly equipped with a cleaning tank 1, and the top outer surfaces of the cleaning tank 1 and the plating solution tank 2 are fixedly connected with a support plate 3, and the adjacent side walls of the two sets of support plates 3 are fixedly connected with a back plate 4, and the back plate 4 is provided with a conveying mechanism 5, and the conveying mechanism 5 is provided with a fixing mechanism 6. Both the cleaning tank 1 and the plating solution tank 2 are provided with an anti-overflow mechanism 7, and one side of the outer wall of the anti-overflow mechanism 7 is provided with a liquid adding ...

Embodiment 2

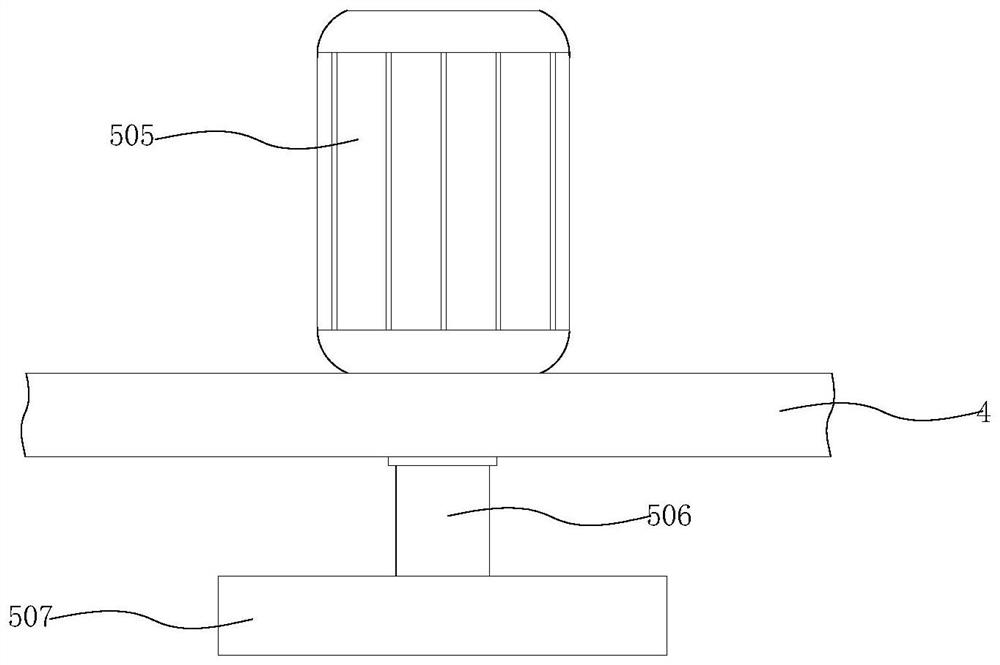

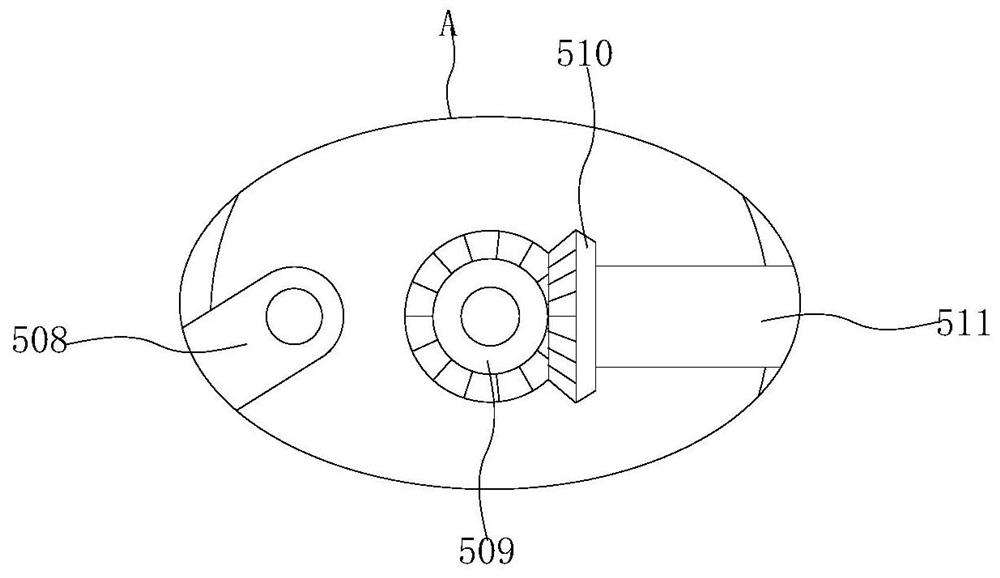

[0030] see Figure 1-8 , on the basis of Embodiment 1, the conveying mechanism 5 includes a long threaded rod 501, a slide plate 502, a slide rod sleeve 503, a slide rod 504, a servo motor 505, a short rotating rod 506, a turntable 507, a connecting rod 508, a first bevel gear 509, the second bevel gear 510, the long rotating rod 511, the first pulley 512, the second pulley 513 and the first belt 514, the adjacent side walls of two groups of support plates 3 are rotatably equipped with long threaded rods 501, long threaded rods 501 A slide plate 502 is arranged on the top, the front outer surface of the slide plate 502 is fixedly connected with a slide bar cover 503, the inside of the slide bar cover 503 is slidably installed with a slide bar 504, and the front outer surface of the back plate 4 is rotatably installed with a short rotating rod 506, A servomotor 505 is fixedly mounted on the rear outer surface of the backplane 4. The output shaft of the servomotor 505 extends to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com