Preparation method of polyacrylic acid/cellulose hydrogel fibers, prepared hydrogel fiber and application thereof

A hydrogel fiber, polyacrylic acid technology, applied in the direction of cellulose/protein conjugated rayon, fiber type, fiber processing, etc., can solve the problems of low mechanical strength, poor electrical conductivity, complex synthesis process, etc., and achieve the synthesis process. Simple and harmless, good adsorption effect, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

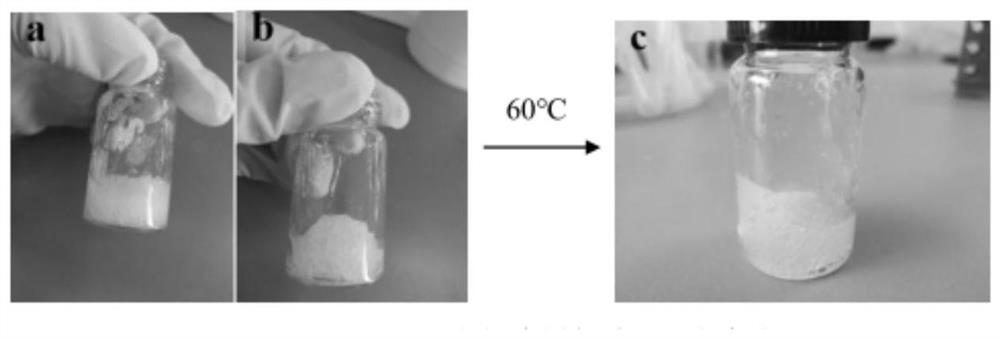

[0092] The preparation method of PAAS / CMC composite hydrogel fiber specifically comprises the following steps:

[0093] (1) Take 0.03 g of sodium carboxymethyl cellulose (CMC) solid powder and dissolve it in a mixed solvent of 4 mL of deionized water and 1 mL of dimethyl sulfoxide solution to obtain a gel.

[0094] (2) Add 0.2 g of sodium polyacrylate (PAAS) and pour it into the jelly, stir until it is completely dissolved, and obtain a uniform translucent jelly.

[0095] (3) The mixture was heated in a water bath at 60° C. and magnetic stirring at 200 rpm for 15 min, and cross-linked to obtain a PAAS / CMC composite hydrogel.

[0096] (4) If there are still large agglomerates after heating in the water bath, slow heating at 70°C for 25min.

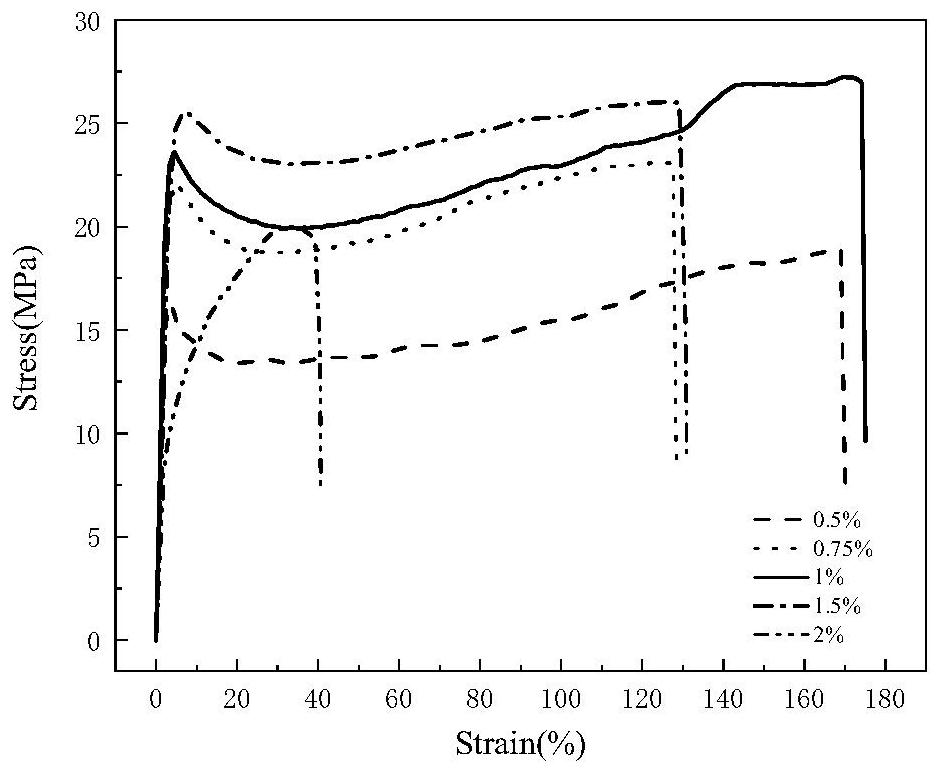

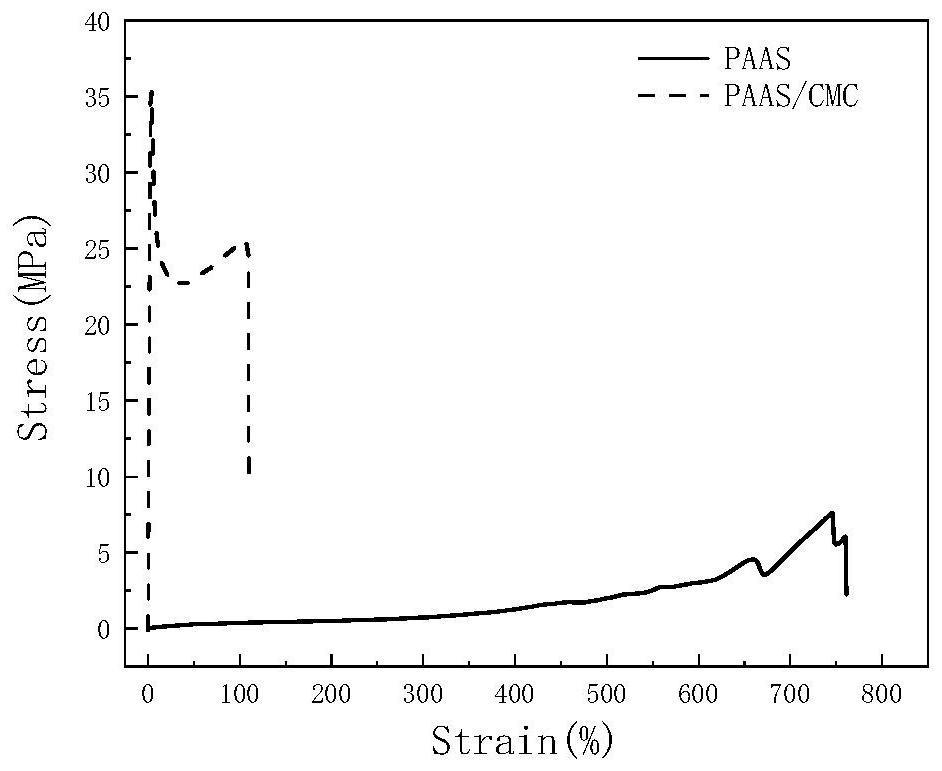

[0097] (5) The PAAS / CMC composite hydrogel was drawn into filamentous fibers by a spinning device. Wherein, in this reaction system, the mass concentration of sodium carboxymethyl cellulose solid powder feeding is 0.6%. The calculation m...

Embodiment 2

[0099] The preparation method of PAAS / CMC composite hydrogel fiber specifically comprises the following steps:

[0100] (1) Take 0.045 g of sodium carboxymethyl cellulose solid powder and dissolve it in a mixed solvent of 4 mL of deionized water and 1 mL of dimethyl sulfoxide solution to obtain a gel.

[0101] (2) Add 0.2 g of sodium polyacrylate and pour it into the jelly, stir until it is completely dissolved, and obtain a uniform translucent jelly.

[0102] (3) The mixture was heated in a water bath at 60° C. and magnetic stirring at 200 rpm for 20 min, and the PAAS / CMC composite hydrogel was obtained by cross-linking.

[0103] (4) If there are still large agglomerates after heating in the water bath, it can be heated at a slow speed of 20min at 80°C.

[0104] (5) The PAAS / CMC composite hydrogel was drawn into filamentous fibers by a spinning device. Wherein, in this reaction system, the mass concentration of sodium carboxymethyl cellulose solid powder feeding is 0.85%. ...

Embodiment 3

[0106] The preparation method of PAAS / CMC composite hydrogel fiber specifically comprises the following steps:

[0107] (1) Take 0.06 g of sodium carboxymethyl cellulose solid powder and dissolve it in a mixed solvent of 4 mL of deionized water and 1 mL of dimethyl sulfoxide solution to obtain a gel.

[0108] (2) Add 0.2 g of sodium polyacrylate and pour it into the jelly, stir until it is completely dissolved, and obtain a uniform translucent jelly.

[0109] (3) The mixture was heated in a water bath at 60° C. and magnetic stirring at 200 rpm for 15 min, and cross-linked to obtain a PAAS / CMC composite hydrogel.

[0110] (4) If there are still large agglomerates after heating in the water bath, it can be heated at a slow speed of 70-80°C for 20min.

[0111] (5) The PAAS / CMC composite hydrogel was drawn into filamentous fibers by a spinning device. Wherein, in this reaction system, the mass concentration of sodium carboxymethyl cellulose solid powder feeding is 1%. The calcu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com