Combined gap type gas steam boiler

A gas-fired steam and gap-type technology, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of large heat loss when starting and stopping the boiler, slow starting and stopping speed of the boiler, and large boiler volume, etc. Steel consumption and water volume, the effect of steel consumption reduction and heat transfer coefficient improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

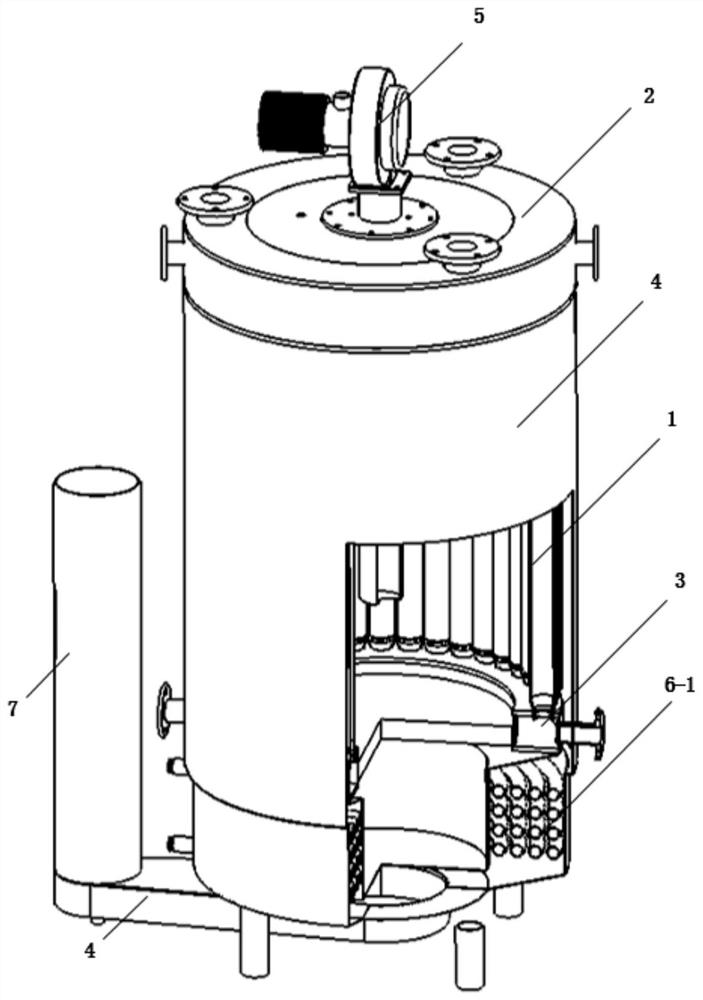

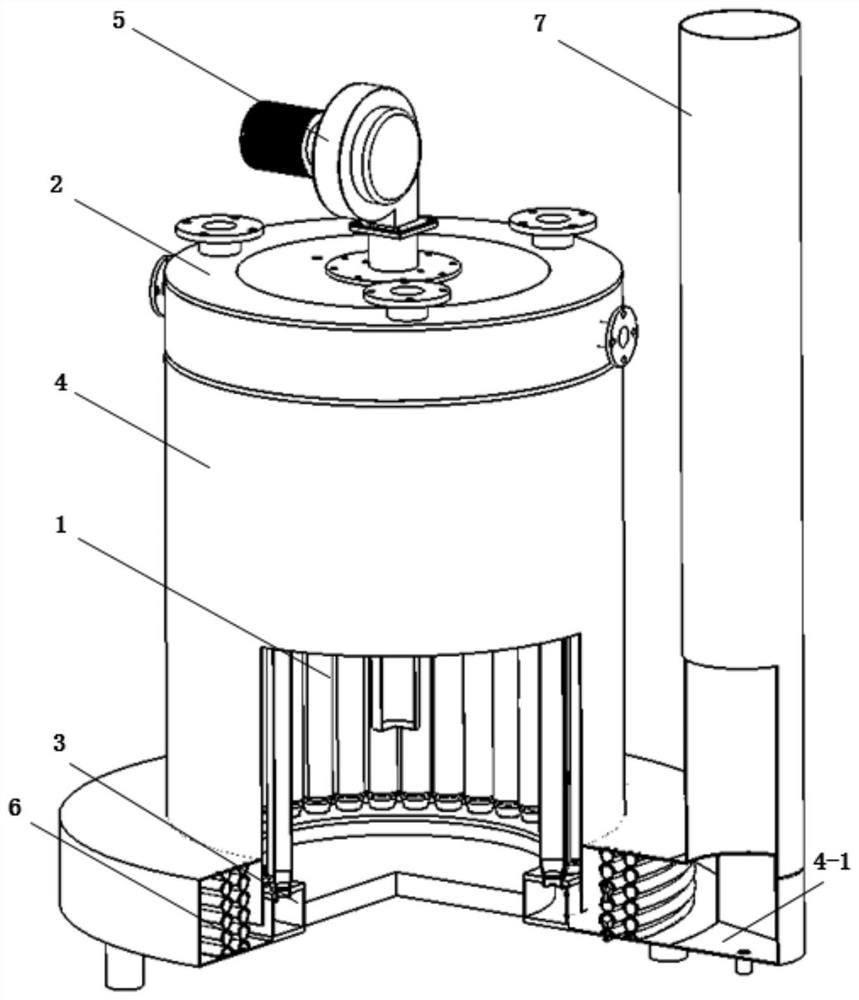

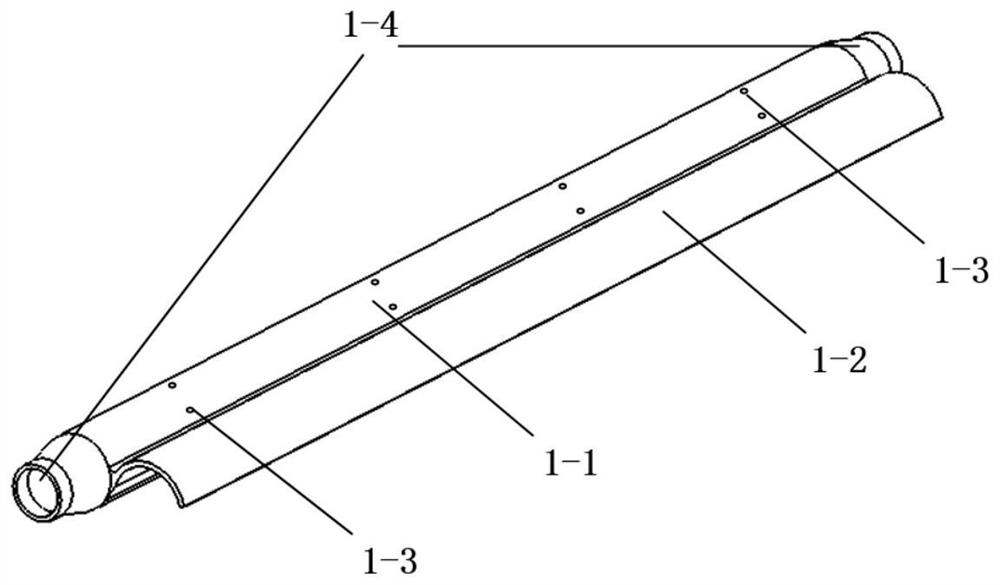

[0037] Such as Figure 1a As shown, the present invention is a combined gap type gas-fired steam boiler. The boiler is vertically arranged, including a tile-finned circular tube 1, an upper header 2, a lower header 3, a smoke case 4, a burner 5, and a condenser 6. , a chimney 7 and a controller; a plurality of tile-finned circular tubes 1 form a vertically arranged annular tube row, and the space surrounded by the annular tube row is the furnace, and the adjacent tile-finned circular tubes 1 are combined to form a circular tube row along the circumference. Evenly distributed axial slot channels, the upper and lower ends of all tile-finned circular tubes 1 extend into the upper header 2 and the lower header 3 respectively; the upper header 2 and the lower header 3 are annular headers, which are in common The cross-section of the surface can be rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com