Separator for lithium metal battery and preparation method thereof

A technology for lithium metal batteries and separators, which is applied to lithium batteries, secondary batteries, battery pack components, etc., can solve the problems of battery gas production and capacity reduction, lithium battery short circuit, electrolyte side reactions, etc., and improve battery safety. Sexuality, reduce energy decay, reduce side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method for the separator of lithium metal battery as above, comprises the following steps:

[0033] S1. Sanding and mixing the conductive agent 31 and the piezoelectric ceramic particles 32 to obtain coating powder;

[0034] S2. Mix the coating powder and binder evenly, add additive CMC and wetting agent BYK-346 to prepare composite slurry;

[0035] S3, coating the composite slurry on the surface of the lithium metal battery separator body 3 .

[0036] working principle:

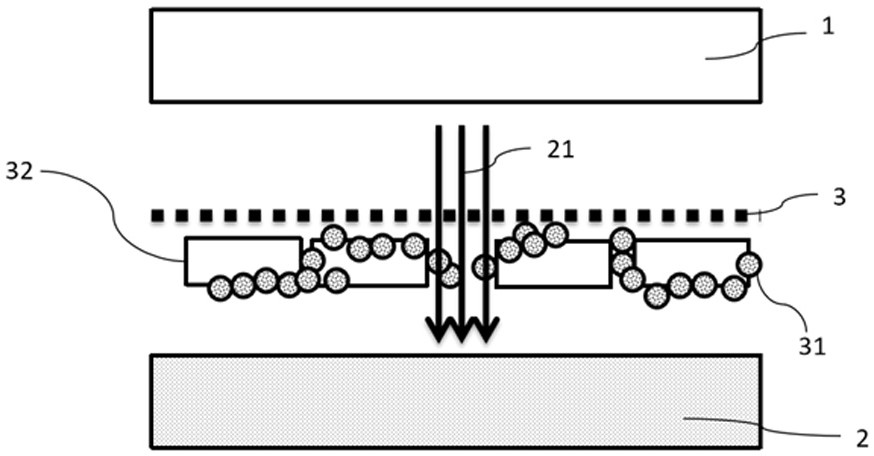

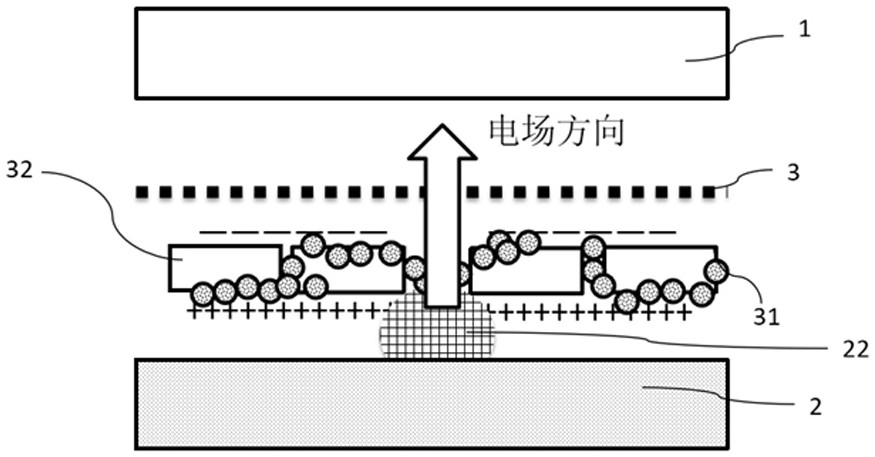

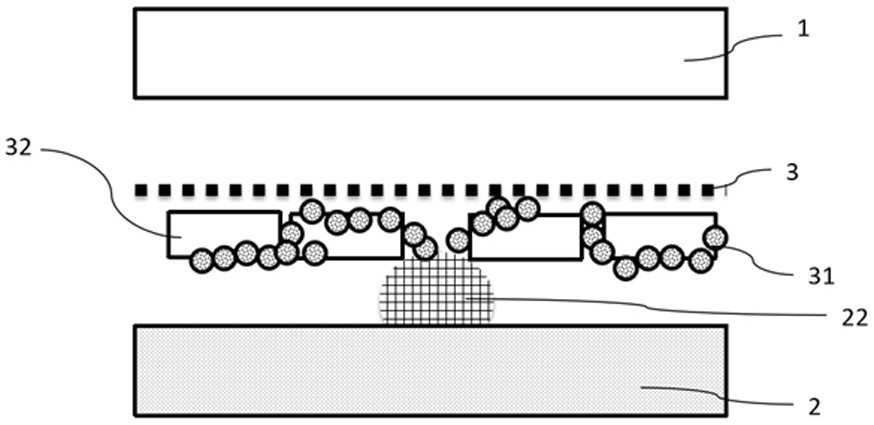

[0037] Lithium ions 21 move from the positive electrode 1 to the negative electrode 2 during charging, forming a charging current. Due to the non-uniform microstructure, the charging current is also non-uniform. Such as Figure 1 to Figure 3 As shown, when the coating separator has a large hole, an excessive charging current will appear here, and if lithium ions 21 are too late to enter the negative electrode 2, lithium metal deposition 22 will occur on the surface of the negative ...

Embodiment 1

[0039]The conductive agent 31 is conductive carbon black, the binder is 40% solid content styrene-butadiene rubber emulsion and CMC, and the piezoelectric ceramic particles 32 are barium titanate. The particle size D50 of barium titanate is 1.2 microns. Conductive agent 31, barium titanate, and deionized water were sand-milled and mixed uniformly at a mass ratio of 2:8:40, and then dried to obtain coating powder. Mix the coating powder, styrene-butadiene rubber emulsion, CMC, wetting agent BYK-346 and deionized water evenly according to the mass ratio of 30:4:0.15:0.1:65.75. Coat on a 9 micron membrane (manufactured by TNS) using a microgravure and dry. The thickness of the piezoelectric ceramic coating is 2 microns after drying.

Embodiment 2

[0041] The difference from Example 1 is that the barium titanate particle size is 0.5 micron, and the coating thickness is 1 micron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com