Additive for improving performance of phosphogypsum cement-based wet-mixed mortar, and preparation method thereof

A wet-mixed mortar and admixture technology, which is applied in the field of building materials, can solve problems such as the inability to meet the performance requirements of phosphogypsum cement-based wet-mixed mortar, and achieve the effect of increasing construction workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] This embodiment also provides a preparation method of phosphogypsum cement-based wet-mix mortar admixture, the specific steps are as follows:

[0029] Step 1: Stir and mix the thickened water-retaining component and the retarding component in a dry powder state and set aside.

[0030] Step 2: Add the water-reducing component and the viscosity modifier component in the formula into the water, stir at 400r / min-450r / min for 3-5min, then reduce the speed to 250-300r / min and stir for 10-15min. Add the evenly mixed powder prepared in step 1.

[0031] Step 3: Add the defoaming component in the formula, and continue to stir at the above stirring speed for 3-5 minutes.

[0032] Step 4: Add the air-entraining component in the formula, reduce the speed to 100-120r / min and stir for 8-10 minutes to get the finished product.

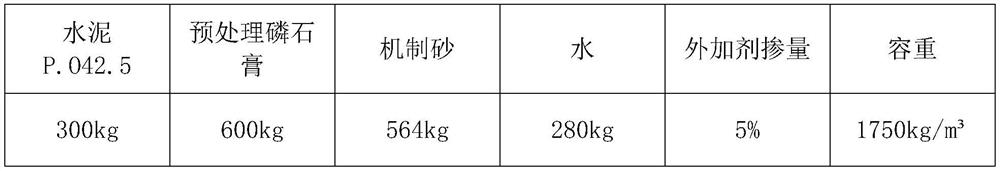

[0033] This embodiment also provides a method for using the above-mentioned admixture. In the method, the amount of the admixture in the phosphogypsum cement...

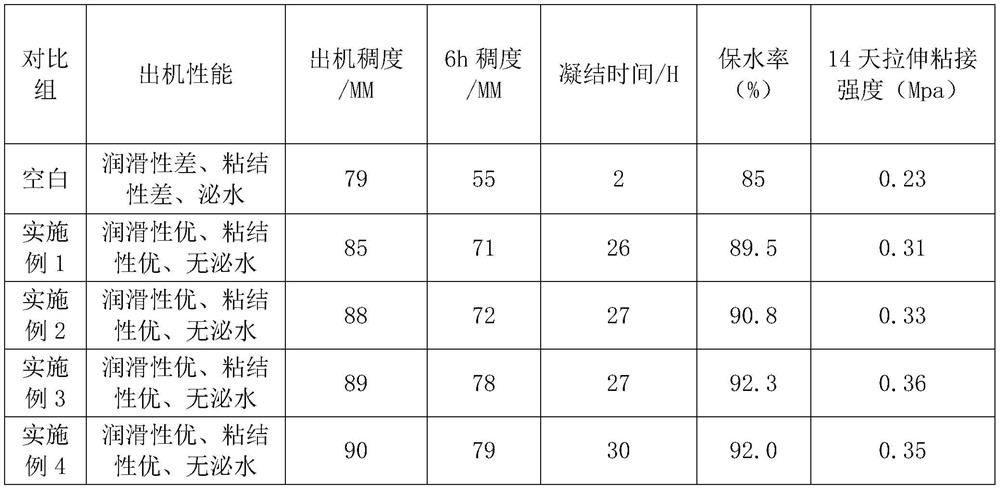

Embodiment 1

[0037] Preparation of an admixture for improving the performance of phosphogypsum cement-based wet-mix mortar:

[0038] Weigh 3g of hydroxypropyl methylcellulose ether, 0.3g of starch ether, 1g of dispersible latex powder, 40g of sodium gluconate, 10g of citric acid, 10g of sodium hexametaphosphate, and 3g of white sugar, and mix and stir evenly in a dry powder state; Take 896.5g of water and put it into a beaker, add 25g of polycarboxylate superplasticizer and 2g of viscosity modifier, stir at 400r / min for 5min; reduce the speed to 300r / min, add the above-mentioned uniformly mixed powder, and continue stirring for 15min. Add 0.2 g of polyether defoamer, and continue stirring for 3 min at 300 r / min. Reduce the speed to 100r / min, add 1g of triterpene saponin and 8g of liquid air-entraining agent, and continue stirring for 10min to obtain the finished product.

Embodiment 2

[0040] Preparation of an admixture for improving the performance of phosphogypsum cement-based wet-mix mortar:

[0041] Weigh 4g of hydroxypropyl methylcellulose ether, 0.6g of starch ether, 1g of dispersible latex powder, 40g of sodium gluconate, 10g of citric acid, 10g of sodium hexametaphosphate, and 3g of white sugar, and mix and stir evenly in a dry powder state; Take 885.2g of water and put it into a beaker, add 35g of polycarboxylate superplasticizer and 2g of viscosity modifier, stir at 400r / min for 5min; reduce the speed to 300r / min, add the above-mentioned uniformly mixed powder, and continue stirring for 15min. Add 0.2 g of polyether defoamer, and continue stirring for 3 min at 300 r / min. Reduce the speed to 100r / min, add 1g of triterpene saponin and 8g of liquid air-entraining agent, and continue stirring for 10min to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com