In-situ generated SiC -doped Gd2Zr2O7 thermal barrier coating ceramic material and preparation method thereof

A technology of ceramic material and thermal barrier coating, applied in the field of thermal barrier coating ceramic material and its preparation, to achieve the effects of high thermal expansion coefficient, low thermal conductivity and good high temperature phase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

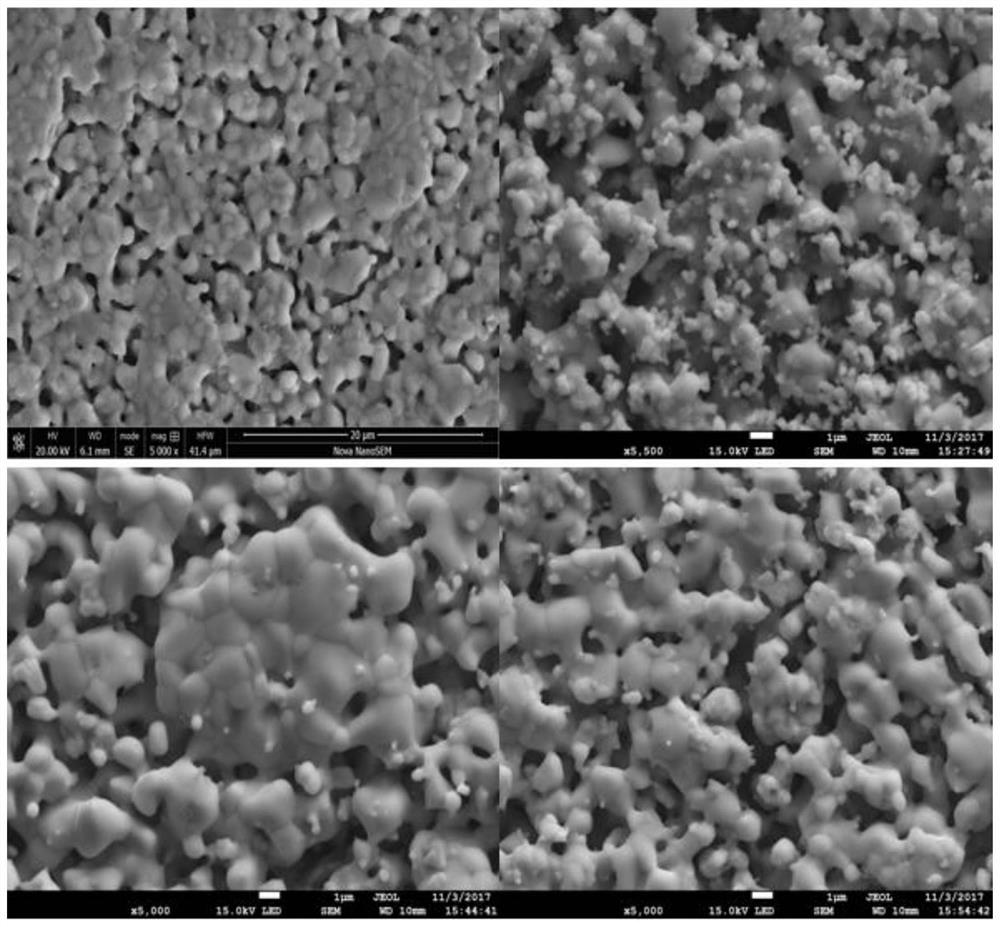

Image

Examples

Embodiment 1

[0038] a pure Gd 2 Zr 2 o 7 Ceramic materials for thermal barrier coatings.

[0039] The pure Gd 2 Zr 2 o 7 The preparation method of thermal barrier coating ceramic material is as follows:

[0040] (1) 0.039 moles of Gd 2 o 3 and 0.078 moles of ZrO 2 Heating to 500°C and holding for 5 hours for drying;

[0041] (2) Mix and dry 0.039 moles of Gd by wet high-energy ball milling 2 o 3 , 0.078 moles of ZrO 2 , ball milled for 10 hours;

[0042] (3) Take out the mixed powder, heat it in a drying oven at 120°C for 10 hours and dry it, and pass through a 300-mesh standard sampling sieve;

[0043] (4) Put the above-mentioned drying powder into a mould, put the mold into a press (diameter of 1.5cm) and press it with a pressure of 250MPa. ℃ for 12 hours, and then cooled with the furnace to prepare the above thermal barrier coating ceramic material.

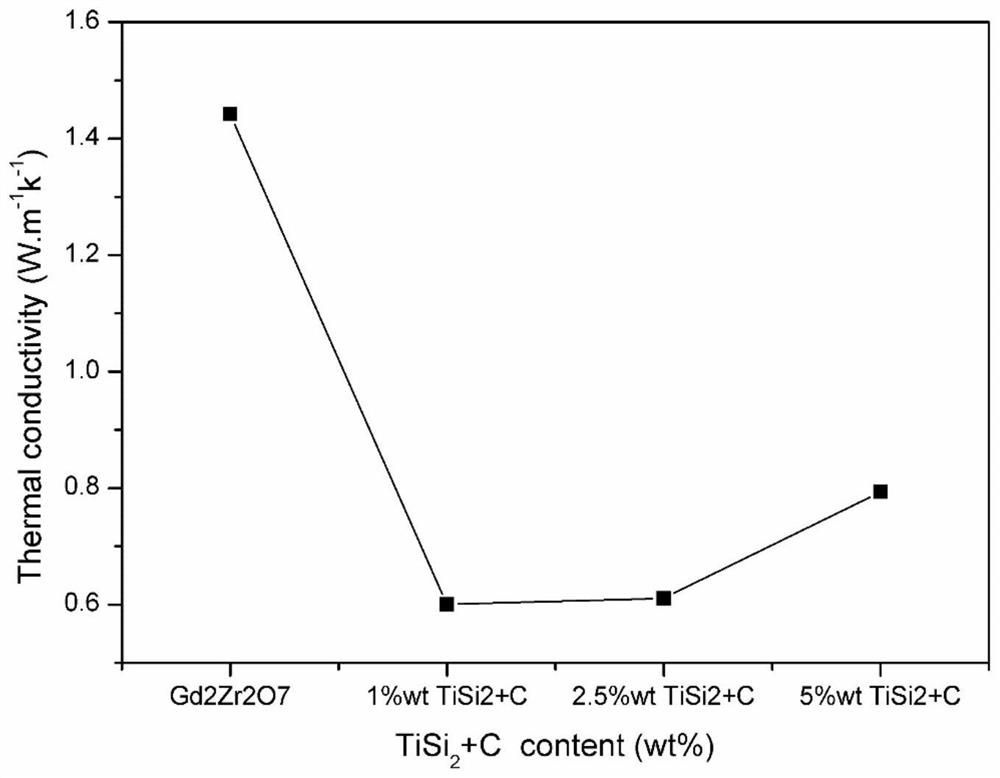

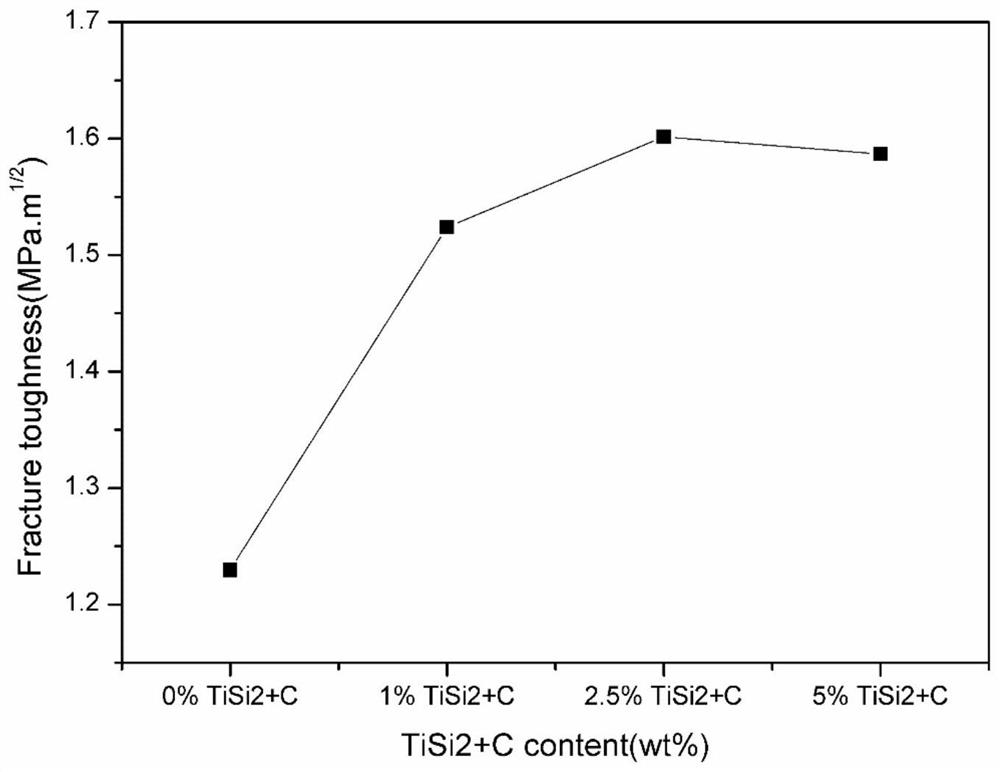

[0044] Pure Gd 2 Zr 2 o 7 The thermal conductivity at 1000 degrees Celsius is 1.44176W m -1 k -1 , and its fracture t...

Embodiment 2

[0046] An in-situ SiC doped Gd 2 Zr 2 o 7 Ceramic materials for thermal barrier coatings.

[0047] The in situ generation of SiC doped Gd 2 Zr 2 o 7 Preparation method of thermal barrier coating ceramic material (TiSi 2 and graphite content are respectively 1wt% and 0.34%):

[0048] (1) 0.024 moles of Gd 2 o 3 and 0.048 moles of ZrO2 heated to 500 ° C, heat preservation for 5 hours for drying;

[0049] (2) Mix and dry 0.024 moles of Gd by wet high-energy ball milling 2 o 3 , 0.048 moles of ZrO 2 , and 0.0015 moles of TiSi 2 and 0.004 mole of graphite, ball milled for 10 hours;

[0050] (3) Take out the mixed powder, heat it in a drying oven at 120°C for 10 hours and dry it, and pass through a 300-mesh standard sampling sieve;

[0051] (4) Put the above-mentioned drying powder into a mould, put the mold into a press (diameter of 1.5cm) and press it with a pressure of 250MPa. ℃ for 12 hours, and then cooled with the furnace to prepare the above thermal barrier coa...

Embodiment 3

[0054] An in-situ SiC doped Gd 2 Zr 2 o 7 Ceramic materials for thermal barrier coatings.

[0055] The in situ generation of SiC doped Gd 2 Zr 2 o 7 Preparation method of thermal barrier coating ceramic material (TiSi 2 and graphite content are respectively 2.5wt% and 0.85wt%):

[0056] (1) 0.024 moles of Gd 2 o 3 and 0.048 moles of ZrO 2 Heating to 500°C and holding for 5 hours for drying;

[0057] (2) Mix and dry 0.024 moles of Gd by wet high-energy ball milling 2 o 3 , 0.048 moles of ZrO 2 , and 0.0036 moles of TiSi 2 and 0.01 mole of graphite, ball milled for 10 hours;

[0058] (3) Take out the mixed powder, heat it in a drying oven at 120°C for 10 hours and dry it, and pass through a 300-mesh standard sampling sieve;

[0059] (4) Put the above-mentioned drying powder into a mould, put the mold into a press (diameter of 1.5cm) and press it with a pressure of 250MPa. ℃ for 12 hours, and then cooled with the furnace to prepare the above thermal barrier coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com