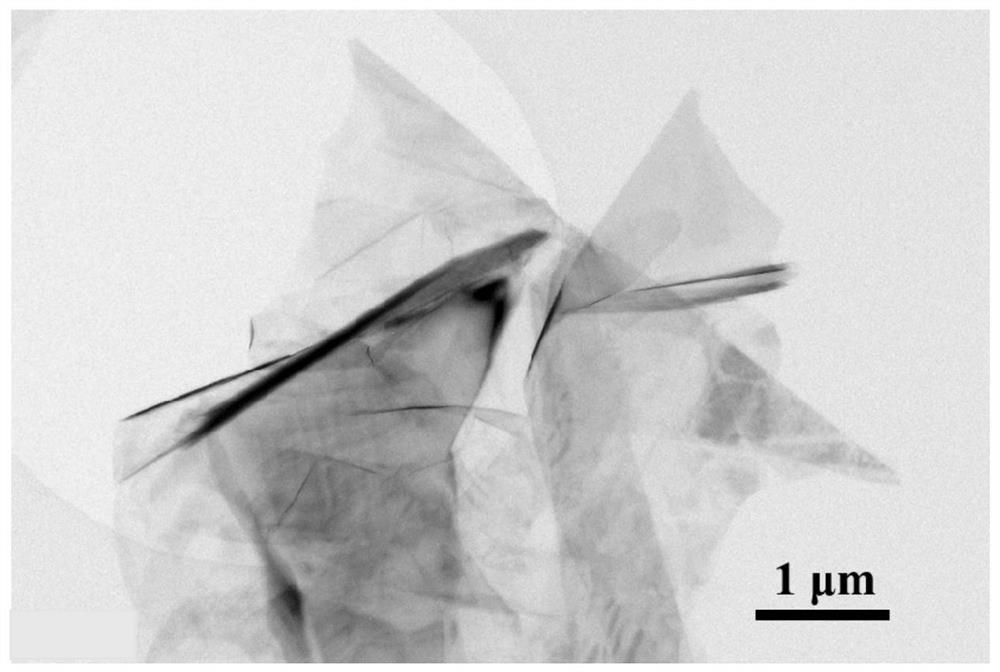

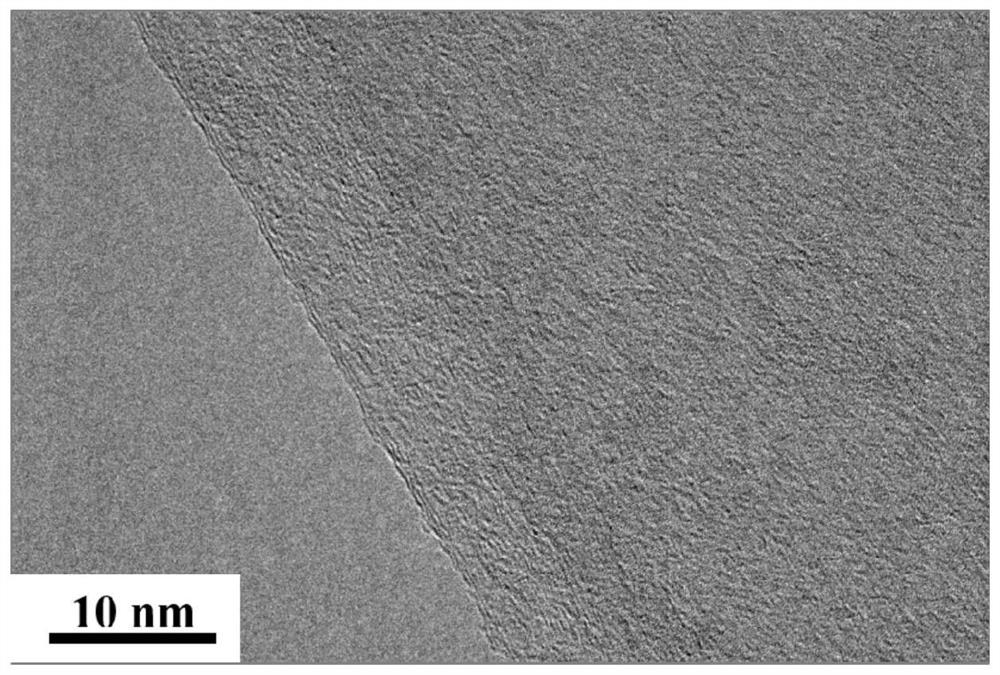

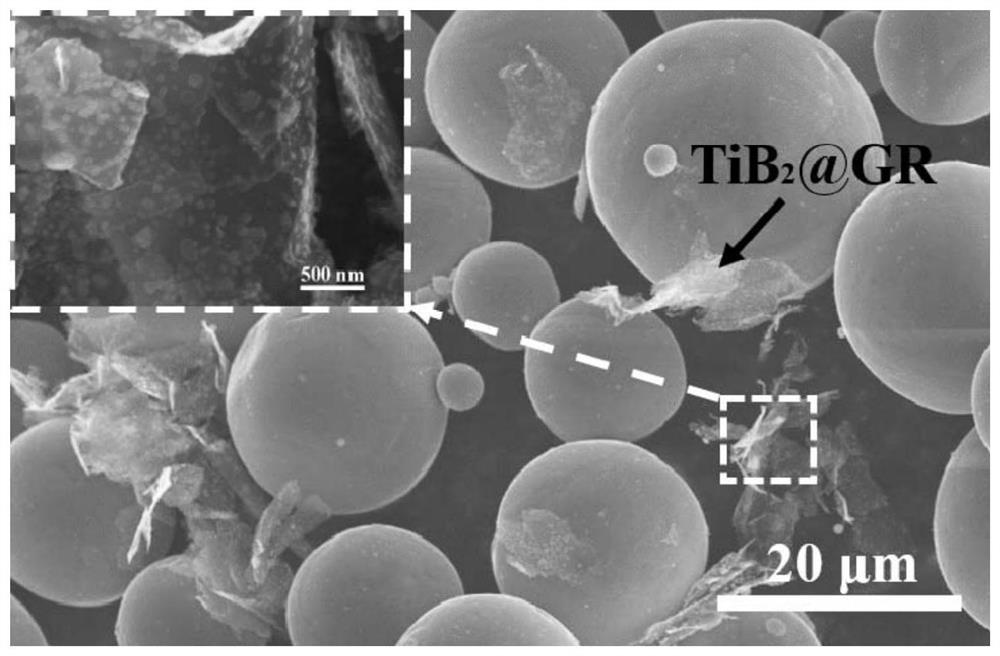

Method for preparing directionally-grown TiBw reinforced titanium matrix composite based on graphene templating

A titanium-based composite material and directional growth technology, which is applied in the field of titanium-based composite material preparation, can solve the problems of decreased load transfer strengthening effect of reinforcement, reduced mechanical properties of composite materials, texture effect of composite materials, etc., to achieve excellent dynamic mechanical properties , maintain structural integrity, high resistance to impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The steps of preparing directional growth TiBw-reinforced titanium-based composites based on graphene templates are as follows:

[0058] (1) Acidification-sensitization treatment of GR

[0059] 1.1) Combine GR and H 3 PO 4 Mix according to the volume ratio of 20:80, and obtain evenly dispersed GR-H after ultrasonic dispersion for 15 minutes 3 PO 4 suspension;

[0060] 1.2) According to GR and KMnO 4 1:1 mass ratio to GR-H 3 PO 4 Add 0.2g KMnO to the suspension 4 , stirring to make KMnO 4 After dissolving, place it in a water bath at 40°C for heating for 2 hours. After the reaction, filter, wash with deionized water, and dry in vacuum to obtain acidified GR;

[0061] 1.3) 19.3mL of pure water, 0.7mL of 37% concentrated hydrochloric acid and 0.76g of SnCl 2 Prepared as a sensitization solution; 0.2 g of acidified GR was added to 20 mL of sensitization solution and stirred for 1 hour, then filtered, washed with deionized water, and then vacuum-dried to obtain sen...

Embodiment 2

[0073] The steps of preparing directional growth TiBw-reinforced titanium-based composites based on graphene templates are as follows:

[0074] (1) Acidification-sensitization treatment of GR

[0075] 1.1) Combine GR and H 3 PO 4 Mix according to the volume ratio of 5:95, and obtain uniformly dispersed GR-H after ultrasonic dispersion for 60 minutes 3 PO 4 suspension;

[0076] 1.2) According to GR and KMnO 4 1:2 mass ratio to GR-H 3 PO 4 1.0 g KMnO was added to the suspension 4 , stirring to make KMnO 4 After dissolving, place it in a water bath at 60°C for heating reaction for 2 hours, filter and wash with deionized water after the reaction, and then dry in vacuum to obtain acidified GR;

[0077] 1.3) 98.25mL of pure water, 1.75mL of 37% concentrated hydrochloric acid and 1.90g of SnCl 2 Prepare a sensitization solution; add 0.5 g of acidified GR into 100 mL of sensitization solution and stir for 2 hours, then filter, wash with deionized water, and dry in vacuum to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com