Lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery and separator technology, which is used in secondary batteries, battery pack components, and secondary battery repair/maintenance, etc., can solve hidden dangers and other problems, achieve good protection and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

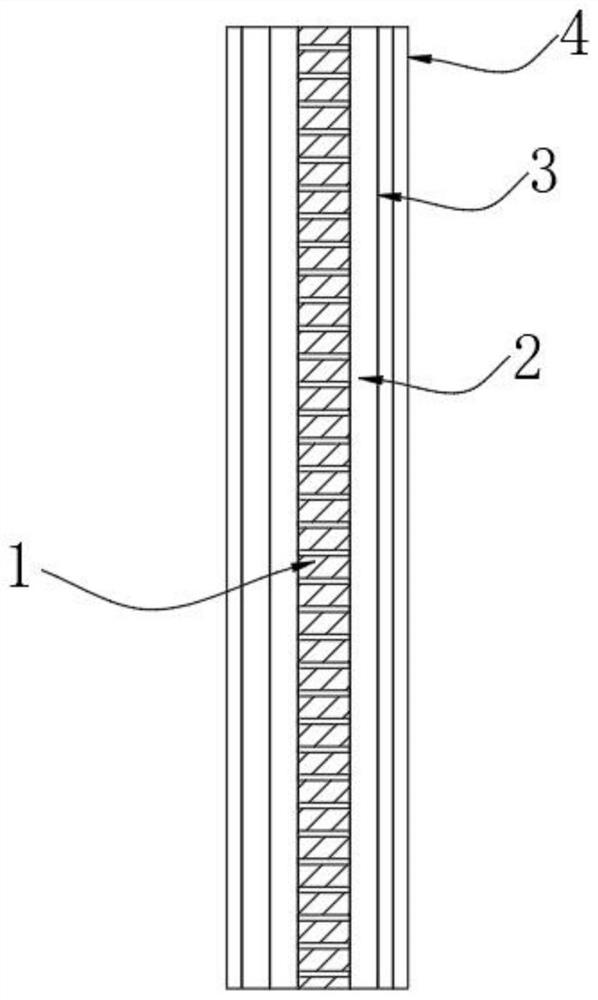

[0023] see figure 1 with 2 , the present invention provides a technical solution: a lithium-ion battery separator, including a microporous membrane 1, the outer two walls of the microporous membrane 1 are coated with a silicon dioxide coating 2, and the outer side walls of the silicon dioxide coating 2 The aramid fiber layer 3 is bonded, and the outer wall of the aramid fiber layer 3 is coated with a ceramic coating 4 .

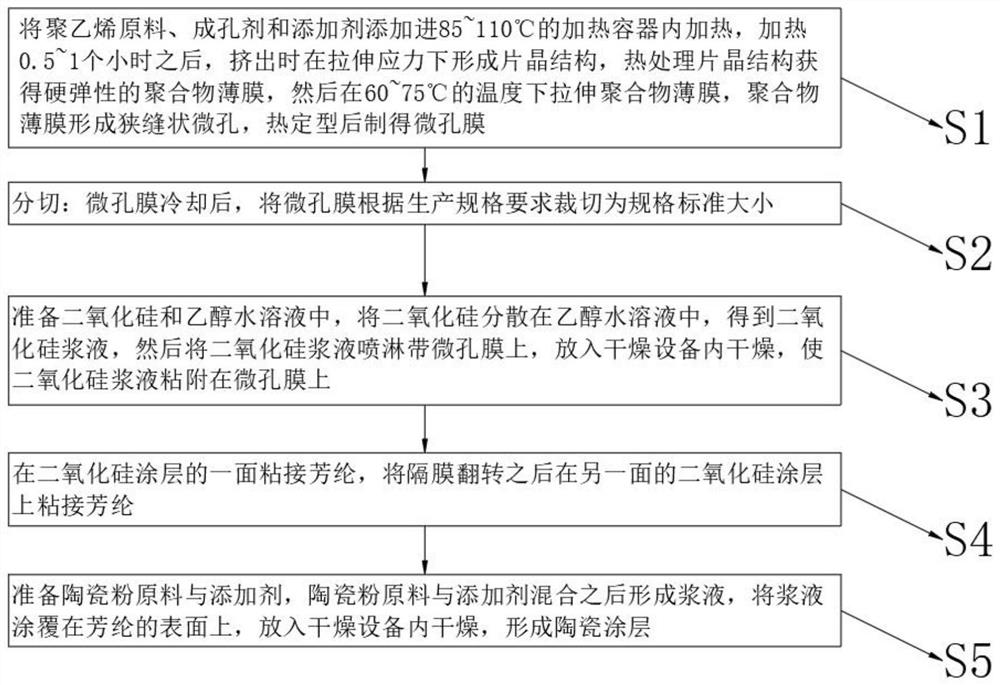

[0024] A preparation method of a lithium-ion battery diaphragm, comprising the following steps:

[0025] S1. Add polyethylene raw materials, pore-forming agents and additives into a heating container at 85°C and heat. After heating for 1 hour, a lamella structure is formed under tensile stress during extrusion, and a hard and elastic polymer film is obtained by heat-treating the lamella structure. , and then stretch the polymer film at a temperature of 60°C, the polymer film forms slit-like micropores, and the microporous film is obtained after heat setting...

Embodiment 2

[0037] see figure 1 with 2 , the present invention provides a technical solution: a lithium-ion battery separator, including a microporous membrane 1, the outer two walls of the microporous membrane 1 are coated with a silicon dioxide coating 2, and the outer side walls of the silicon dioxide coating 2 The aramid fiber layer 3 is bonded, and the outer wall of the aramid fiber layer 3 is coated with a ceramic coating 4 .

[0038] A preparation method of a lithium-ion battery diaphragm, comprising the following steps:

[0039] S1. Add polyethylene raw materials, pore-forming agents and additives into a heating container at 90°C and heat. After heating for 0.7h, a lamellar structure is formed under tensile stress during extrusion, and a hard and elastic polymer is obtained by heat-treating the lamellar structure. film, and then stretch the polymer film at a temperature of 35°C, the polymer film forms slit-like micropores, and the microporous film is obtained after heat setting;...

Embodiment 3

[0051] see figure 1 and 2 , the present invention provides a technical solution: a lithium-ion battery separator, including a microporous membrane 1, the outer two walls of the microporous membrane 1 are coated with a silicon dioxide coating 2, and the outer side walls of the silicon dioxide coating 2 The aramid fiber layer 3 is bonded, and the outer wall of the aramid fiber layer 3 is coated with a ceramic coating 4 .

[0052] A preparation method of a lithium-ion battery diaphragm, comprising the following steps:

[0053] S1. Add polyethylene raw materials, pore-forming agents and additives into a heating container at 90°C and heat. After heating for 0.8h, a lamella structure is formed under tensile stress during extrusion, and a hard elastic polymer is obtained by heat-treating the lamella structure. Film, and then stretch the polymer film at a temperature of 70°C, the polymer film forms slit-like micropores, and the microporous film is obtained after heat setting;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com