Heavy metal adsorbent as well as preparation method and application thereof

A heavy metal and adsorbent technology, applied in non-metallic elements, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problems of poor removal of thallium, poor stability, limited application of adsorbent materials, etc., and meet the requirements of reaction conditions Low cost, low cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: preparation adsorbent

[0055] This embodiment prepared titanium tripolyphosphate heavy metal adsorbent-1, the specific process is:

[0056] Weigh 0.2mol Na 5 P 3 o 10 , dissolved in 200mL of water to obtain a solution;

[0057] Add concentrated nitric acid, adjust the pH of the solution to 1, stir the solution rapidly at room temperature, add 0.25molTi(SO 4 ) 2 , continue to stir for 1h, and then stand at room temperature for aging for 24h.

[0058] Pour off the above water, then add 1000mL deionized water, stir and wash for 10min, use suction filtration method for solid-liquid separation, continue to wash the solid filter cake with deionized water 4 times, after separating the adsorbent, put it in the oven Dry at 50°C for 2 hours, then raise the temperature to 100°C and dry for 12 hours to obtain titanium tripolyphosphate heavy metal adsorbent-1.

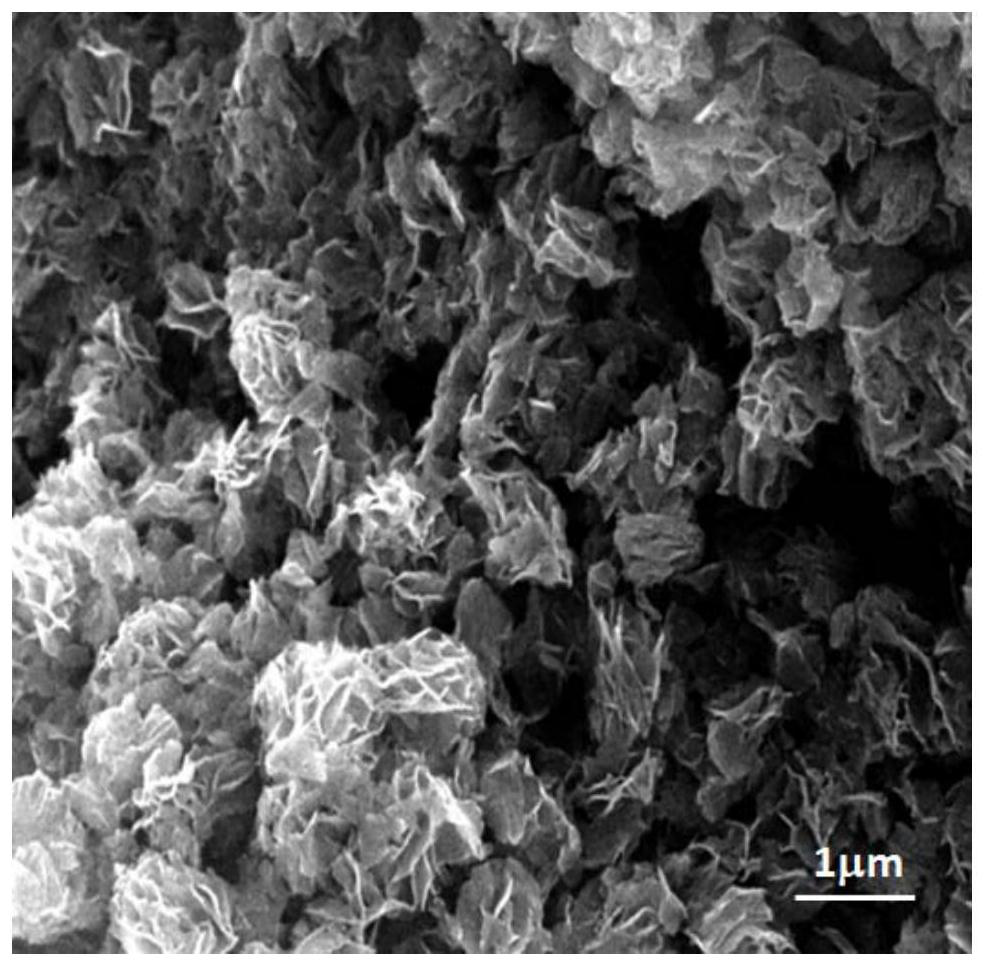

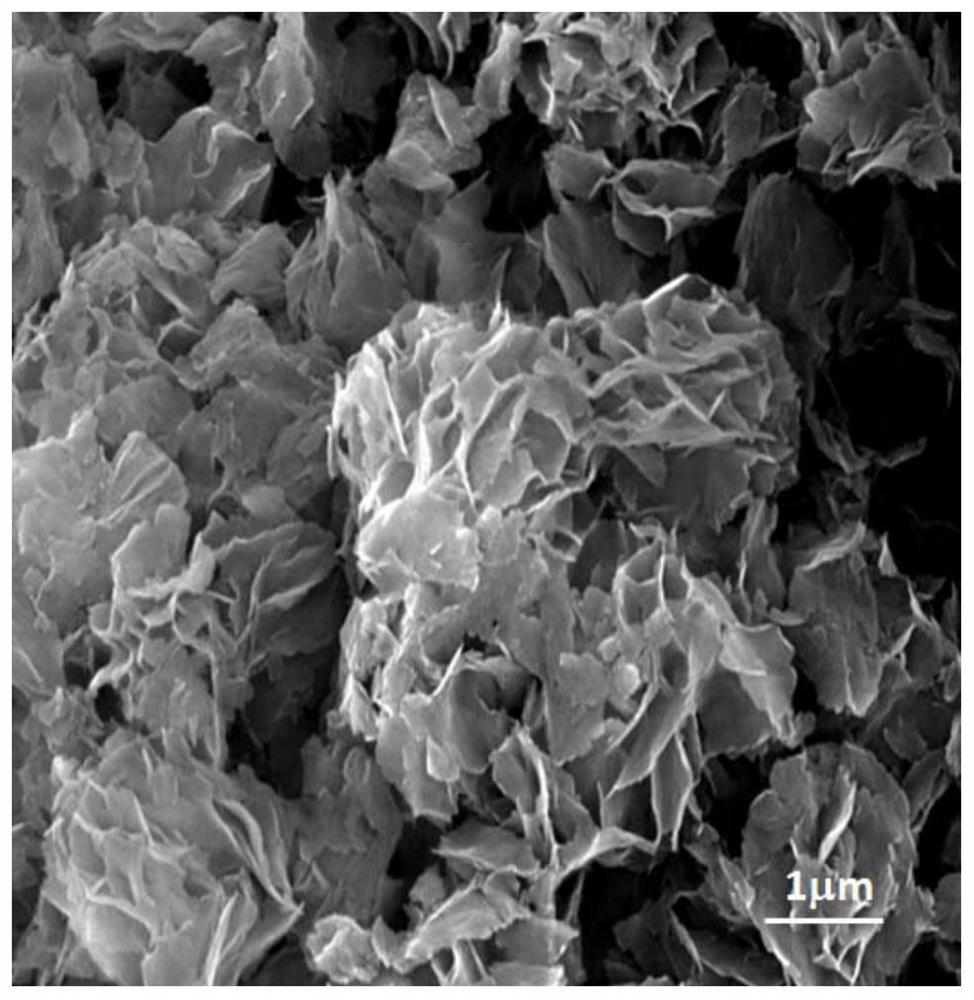

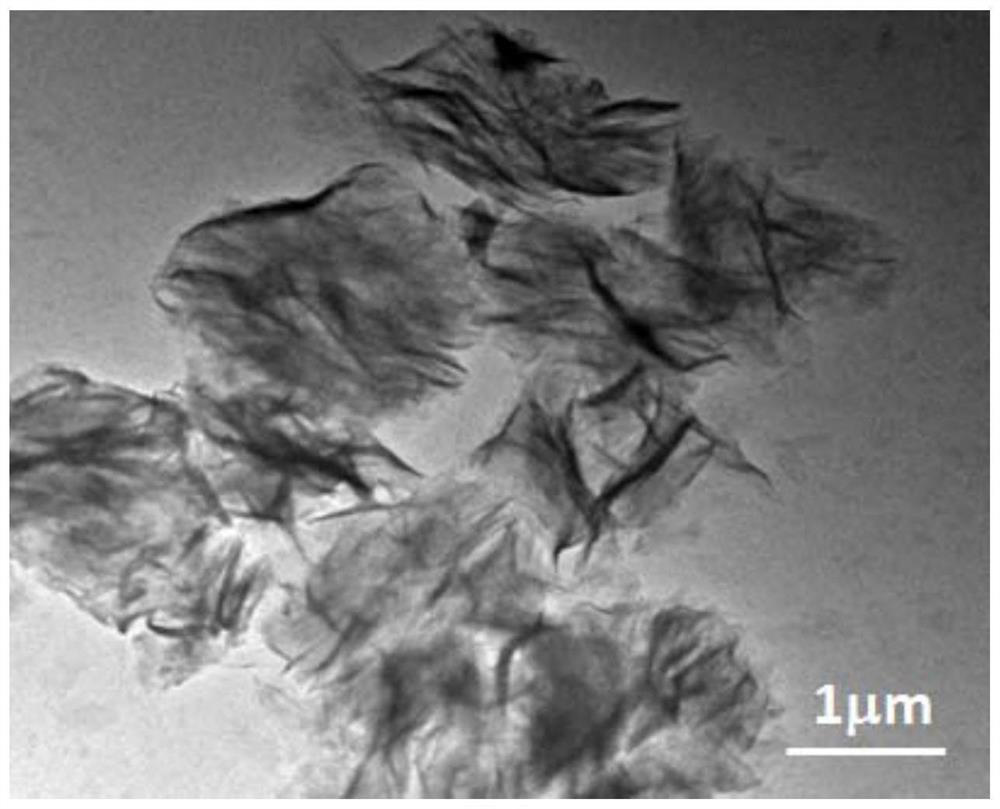

[0059] figure 1 with figure 2 This is the SEM picture of the adsorbent prepared in Example 1. It ...

Embodiment 2

[0061] Embodiment 2: preparation adsorbent

[0062] This embodiment prepared titanium tripolyphosphate heavy metal adsorbent-2, the specific process is:

[0063] Weigh 0.2mol Na 5 P 3 o 10 , dissolved in 200mL of water to obtain a solution;

[0064] Add concentrated nitric acid, adjust the pH of the solution to 2, stir the solution rapidly at room temperature, add 0.4molTi(SO 4 ) 2 . Then the mixture was poured into the reactor, and the hydrothermal reaction was continued in an oven at 100°C for 6h. After completion, take it out and let it stand at room temperature for 12 hours. Pour off the above water, then add 1000mL deionized water, stir and wash for 10min, use suction filtration method for solid-liquid separation, continue to wash the solid filter cake with deionized water for 3 times, after separating the adsorbent, put it in the oven Dry at 55°C for 8 hours, then raise the temperature to 100°C for 8 hours.

Embodiment 3

[0065] Embodiment 3: preparation adsorbent

[0066] This embodiment prepared titanium tripolyphosphate heavy metal adsorbent-3, the specific process is:

[0067] Weigh 0.2molNa 5 P 3 o 10 , dissolved in 200mL of water to obtain a solution;

[0068] Add concentrated nitric acid to adjust the pH of the solution to 0; at room temperature, stir the solution rapidly, add 0.5mol Ti(SO 4 ) 2 . Then the mixture was poured into the reactor, and the hydrothermal reaction was continued in an oven at 150°C for 6h. After completion, take it out and let it stand at room temperature for 8 hours. Pour off the above water, then add 1000mL deionized water, stir and wash for 10min, use suction filtration method for solid-liquid separation, continue to wash the solid filter cake with deionized water 4 times, after separating the adsorbent, put it in the oven Dry at 40°C for 12 hours, then raise the temperature to 100°C and dry for 6 hours to obtain titanium tripolyphosphate heavy metal ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com