Magnetic Fe3O4/Fe2O3 heteroplasmon hollow nanorod material and preparation method and application thereof

A technology of nanorods and heterogeneous bodies is applied in the field of magnetic Fe3O4/Fe2O3 heterogenous hollow nanorod materials and the preparation thereof, which can solve the problems of unfavorable industrialized production, complicated methods of hollow nanorods, etc., and achieves easy large-scale industrial production, The effect of short preparation cycle and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Magnetic Fe of the present invention 3 o 4 / Fe 2 o 3 Preparation of heterogeneous hollow nanorod materials:

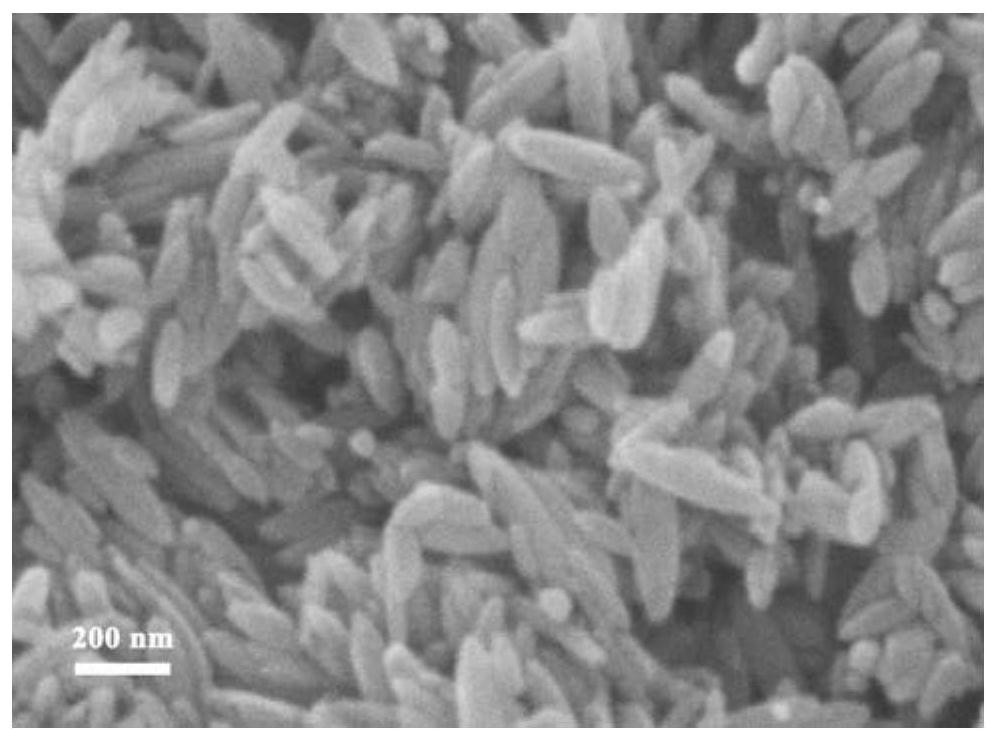

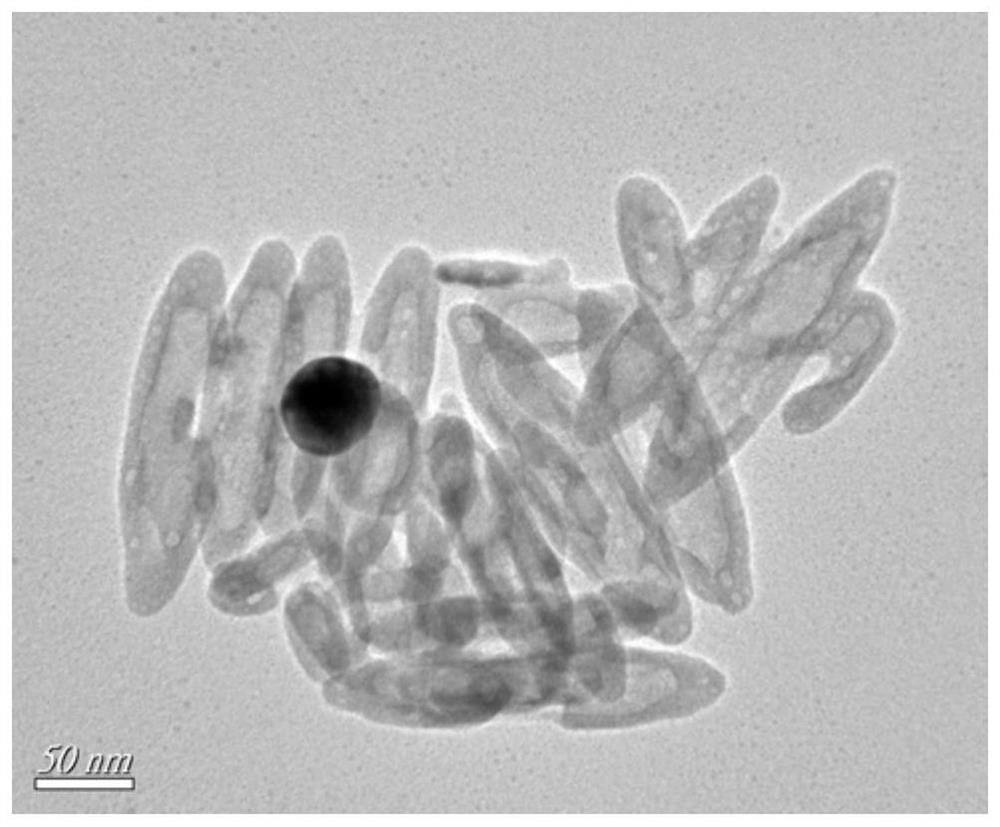

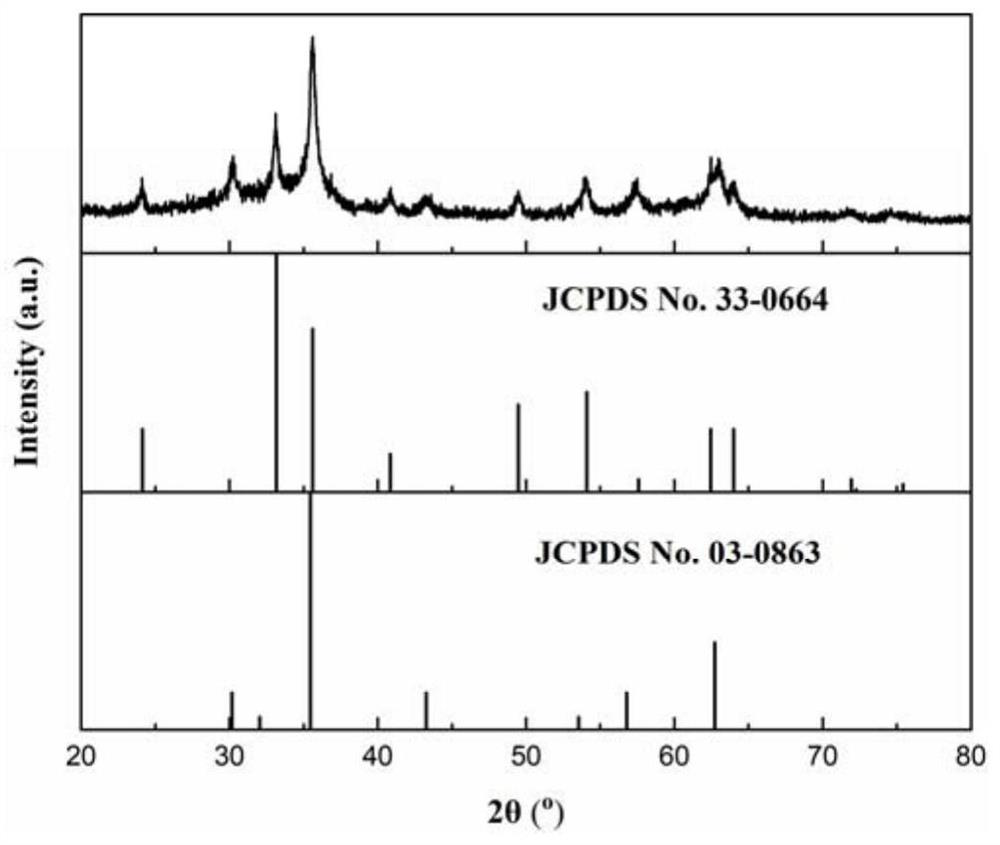

[0036] Add 5.4 g of ferric chloride hexahydrate to 200 mL of double distilled water, and hydrolyze in a water bath at 90° C. for 8 h under magnetic stirring. After the reaction is over, centrifuge the reaction solution while it is hot, wash the precipitate obtained 3 times with water and 3 times with alcohol, disperse the precipitate after alcohol washing in a crucible filled with 30mL of absolute ethanol, ignite and burn, and sinter the product together with Put the crucible together in a programmable temperature-controlled furnace, raise the temperature to 300°C at a heating rate of 3°C / min, and keep it for calcination at 300°C for 2 hours, then take it out after naturally cooling to room temperature, and grind it to obtain magnetic Fe 2 o 3 / Fe 3 o 4 Heterogeneous hollow nanorods. Preparation of magnetic Fe 2 o 3 / Fe 3 o 4 The overall length of th...

Embodiment 2

[0041] Magnetic Fe of the present invention 3 o 4 / Fe 2 o 3 Preparation of heterogeneous hollow nanorod materials:

[0042] Add 5.4 g of ferric chloride hexahydrate to 200 mL of double distilled water, and hydrolyze in a water bath at 85° C. for 10 h under magnetic stirring. After the reaction is over, centrifuge the reaction solution while it is hot, wash the precipitate obtained 3 times with water and 3 times with alcohol, disperse the precipitate after alcohol washing in a crucible filled with 20mL of absolute ethanol, ignite and burn, and sinter the product together with Put the crucible together in a temperature-programmed furnace, raise the temperature to 350°C at a heating rate of 3°C / min, and keep it for calcination at 350°C for 2 hours, then take it out after naturally cooling to room temperature, and grind it to obtain magnetic Fe 2 o 3 / Fe 3 o 4 Heterogeneous hollow nanorods. Preparation of magnetic Fe 2 o 3 / Fe 3 o 4 The overall length of the heterogene...

Embodiment 3

[0044] Magnetic Fe of the present invention 3 o 4 / Fe 2 o 3 Preparation of heterogeneous hollow nanorod materials:

[0045] Add 5.4 g of ferric chloride hexahydrate to 200 mL of double distilled water, and hydrolyze in a water bath at 80° C. for 16 h under magnetic stirring. After the reaction is over, centrifuge the reaction solution while it is hot, wash the precipitate obtained 3 times with water and 3 times with alcohol, disperse the precipitate after alcohol washing in a crucible filled with 40mL of absolute ethanol, ignite and burn, and sinter the product together with Put the crucible together in a temperature-programmed furnace, raise the temperature to 400°C at a heating rate of 3°C / min, and keep it for calcination at 400°C for 2 hours, then take it out after natural cooling to room temperature, and grind it to obtain magnetic Fe 2 o 3 / Fe 3 o 4 Heterogeneous hollow nanorods. Preparation of magnetic Fe 2 o 3 / Fe 3 o 4 The overall length of the heterogeneou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Overall length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com