Acipimox urea eutectic crystal

A technology of acyclolimus and urea, which is applied in the field of acyclolimus-urea co-crystal, can solve the problems of low yield, less crystalline co-crystal structure, and no characterization parameters are mentioned, and achieves high solubility and hygroscopicity. Low, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

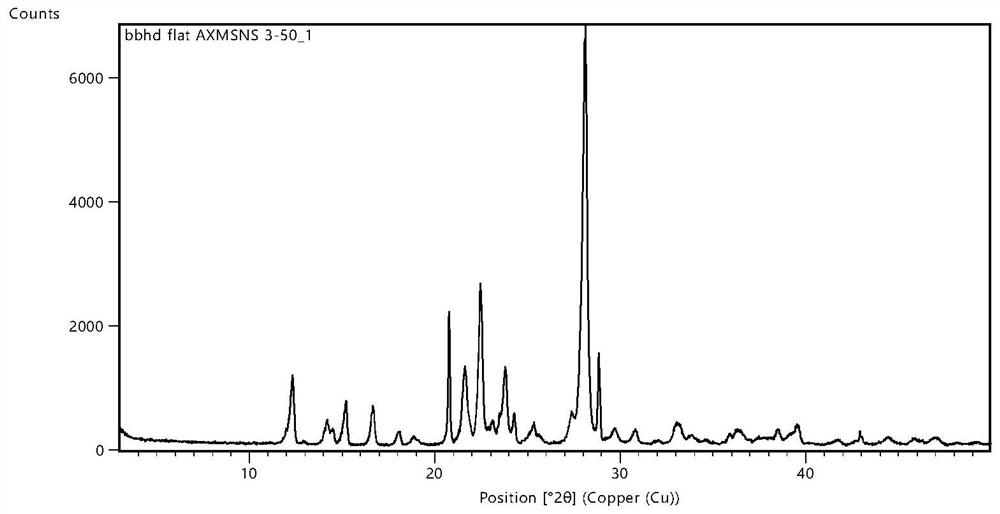

[0056] Add 154.1mg of acipimox (1mmol) and 126.1mg of urea (2.1mmol) into 20ml of methanol, heat and stir to dissolve, reflux for 10 hours, slowly lower the temperature to 2-4°C, and stand for crystallization under temperature control for 48 hours, filtered, washed the filter cake with acetonitrile, and vacuum-dried at 50°C for 12 hours to obtain urea-acipimus eutectic with a yield of 97.33% and a purity of 99.95%.

Embodiment 2

[0058] Add 154.1mg of acipimox, 123.1mg of urea (2.05eq)) into 30ml of mixed solvent (18ml of methanol + 12ml of ethyl acetate), heat and stir to dissolve, reflux for 12 hours, and slowly cool down to 1-5°C, The crystallization was carried out under temperature control for 45 hours, filtered, the filter cake was washed with acetone, and vacuum-dried at 70° C. for 8 hours to obtain urea acipimus eutectic with a yield of 96.56% and a purity of 99.94%.

Embodiment 3

[0060] Add 154.1mg of acipimox and 129.1mg of urea (2.15eq) into 23.5ml of ethyl acetate, heat and stir to dissolve, reflux for 7 hours, slowly lower the temperature to 5-10°C, and stand for crystallization under temperature control for 60 hours , filtered, washed the filter cake with acetonitrile, and vacuum-dried at 60°C for 10 h to obtain urea-acipimus eutectic with a yield of 95.98% and a purity of 99.89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com