Nanomaterial and preparation method thereof, optical thin film and light-emitting device

A technology of nanomaterials and optical thin films, which is applied in the field of optical thin films and light-emitting devices, nanomaterials and their preparation, and can solve the problems of poor luminescence properties of fluorescent nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

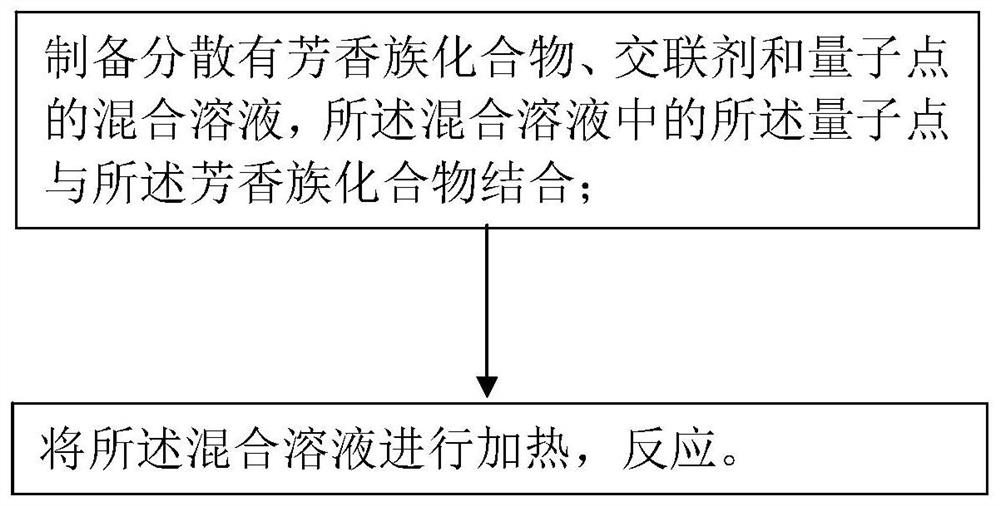

Method used

Image

Examples

Embodiment approach

[0022] As an embodiment, the particle diameter of the quantum dots is 5-16 nanometers, and the particle diameter of the aromatic polymer gel particles is less than 100 nanometers. By adjusting the particle diameters of the quantum dots and the aromatic polymer gel particles within the above range, the luminescent properties of the nanomaterials can be effectively improved on the premise of ensuring that the quantum dots have a good quantum effect. When the particle size of the aromatic polymer gel particle is greater than 100 nanometers, the aromatic polymer layer covering the outer surface of the quantum dot is too thick, and the effect of improving the luminescence performance of the nanomaterial cannot be achieved.

[0023] Specifically, the aromatic polymer gel particle is a kind of three-dimensional network structure material composed of amphiphilic polymer chains, which has the characteristic that the gel can be swelled in the solvent, and can be uniformly dispersed in th...

Embodiment 1

[0088] This embodiment provides an optical film, the preparation of which specifically includes the following steps:

[0089] Disperse 0.3mmol of 2,6-dihydroxyphenol and 1.5mg of CdSe quantum dots in 20mL of solvent (dimethylformamide / water, volume ratio 8:2), add 0.5mmol of 1,3,5 -Trimethylhexylhydroxy-1,3,5-triazine, continue to stir until the mixture is homogeneous, put the mixture into a 30 mL glass container, and then stir and heat in a microwave reactor at 150° C. for 5 min. Then, the reaction product was centrifuged at 20,000 rpm for 40 minutes at a high speed, collected and washed with dimethylformamide, and dried to obtain a CdSe / 2,6-dihydroxyphenol nanomaterial;

[0090] Disperse 2 mg of the above nanomaterials in 20 mL of ethyl acetate to obtain a nanomaterial solution; dissolve 100 mg of polymethyl methacrylate in 10 mL of ethyl acetate to obtain a polymethyl methacrylate solution; Mix equal volumes of methyl acrylate solution, cast the mixture on a glass plate, a...

Embodiment 2

[0093] This embodiment provides an optical film, the preparation of which specifically includes the following steps:

[0094] 0.2mmol of 2,6-dihydroxynaphthalene and 1.5mg of CdSe 1-x S x / CdSe y S 1-y / CdS quantum dots were dispersed in 20 mL of solvent (dimethylformamide / water, volume ratio 7:3), and 0.3 mmol of 1,3,5-trimethylhexylhydroxy-1,3,5-tris Continue to stir until the mixture is homogeneous, put the mixture into a 30mL glass container, and then stir and heat in a microwave reactor at 170°C for 4min. Then, the reaction product was centrifuged at 25,000 rpm for 30 min at high speed, collected and washed with dimethylformamide, and dried to obtain CdSe 1-x S x / CdSe y S 1-y / CdS / 1,3,5-trimethylhexylhydroxy-1,3,5-triazine nanomaterials;

[0095] Disperse 3mg of the above-mentioned nanomaterials in 20mL dimethyl sulfoxide to obtain a nanomaterial solution; dissolve 110mg of polyvinyl alcohol in 10mL of dimethyl sulfoxide to obtain a polyvinyl alcohol solution; mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com