Method for safely recycling waste pole piece of lithium ion battery, and application thereof

A lithium-ion battery and pole piece technology, which is applied in the field of safe recycling of lithium-ion battery waste pole pieces, can solve problems such as obvious production process limitations, explosion, combustion, etc., so as to reduce the probability of ignition, ensure safety, and eliminate fire or explosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

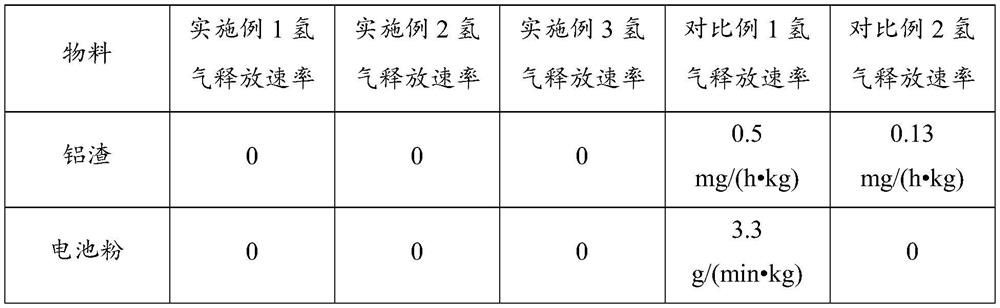

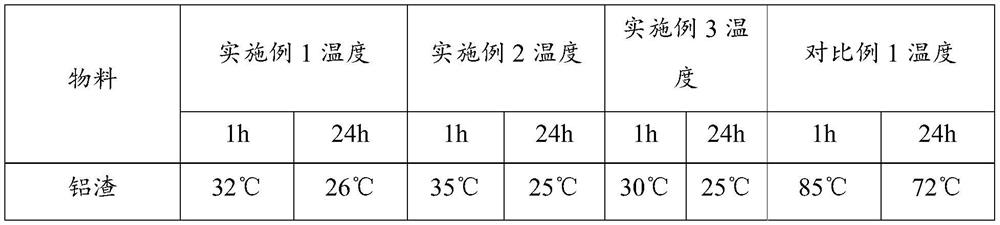

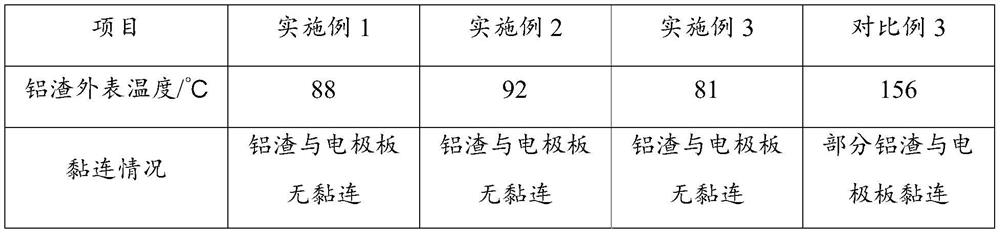

Embodiment 1

[0042] The method for the safe recovery of lithium-ion battery waste pole pieces of the present embodiment comprises the following specific steps:

[0043](1) Crushing and sieving the waste positive electrode sheet to obtain positive electrode powder A and crushed aluminum slag;

[0044] (2) Mix the crushed aluminum slag with 0.1mol / L sulfuric acid at a solid-to-liquid ratio of 1:5kg / L, and ultrasonically while stirring, the stirring speed is 500r / min, and the mixing time is 60min, to obtain the crushed aluminum after pickling slag;

[0045] (3) Adopt wet sieving to sieve the crushed aluminum slag after pickling, take out the sieve from the acid solution, which is mainly aluminum slag, and the sieve is mainly battery powder, and filter the sieve, Take the filter residue and wash the filter residue with water to obtain positive electrode powder B;

[0046] (4) Mix positive electrode powder A and positive electrode powder B, add 0.003mol / L calcium hydroxide solution according ...

Embodiment 2

[0051] The method for the safe recovery of lithium-ion battery waste pole pieces of the present embodiment comprises the following specific steps:

[0052] (1) Crushing the waste positive electrode sheet, passing through a screen with a pore size of 0.3 mm, to obtain positive electrode powder A and crushed aluminum slag;

[0053] (2) Mix the crushed aluminum slag with 1mol / L sulfuric acid at a solid-to-liquid ratio of 1:1kg / L, and ultrasonically while stirring, the stirring speed is 500r / min, and the mixing time is 5min, to obtain the crushed aluminum slag after pickling ;

[0054] (3) Adopt wet sieving to sieve the crushed aluminum slag after pickling, take out the sieve from the acid solution, which is mainly aluminum slag, and the sieve is mainly battery powder, and filter the sieve, Take the filter residue and wash the filter residue with water to obtain positive electrode powder B;

[0055] (4) Mix positive electrode powder A and positive electrode powder B, add 0.5mol / ...

Embodiment 3

[0060] The method for the safe recovery of lithium-ion battery waste pole pieces of the present embodiment comprises the following specific steps:

[0061] (1) Crushing and sieving the waste positive electrode sheet to obtain positive electrode powder A and crushed aluminum slag;

[0062] (2) Mix the crushed aluminum slag with 2mol / L sulfuric acid at a solid-to-liquid ratio of 1:0.3kg / L, ultrasonically while stirring, the stirring speed is 500r / min, and the mixing time is 60min to obtain the crushed aluminum after pickling slag;

[0063] (3) Adopt wet sieving to sieve the crushed aluminum slag after pickling, take out the sieve from the acid solution, which is mainly aluminum slag, and the sieve is mainly battery powder, and filter the sieve, Take the filter residue and wash the filter residue with water to obtain positive electrode powder B;

[0064] (4) Mix positive electrode powder A and positive electrode powder B, add 2mol / L potassium hydroxide solution according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com