Black phosphorus material as well as preparation method and application thereof

A technology for preparing black phosphorus and drugs, which is applied in the field of two-dimensional materials and can solve problems such as inability to improve dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment has prepared a kind of black phosphorus material, and specific process is:

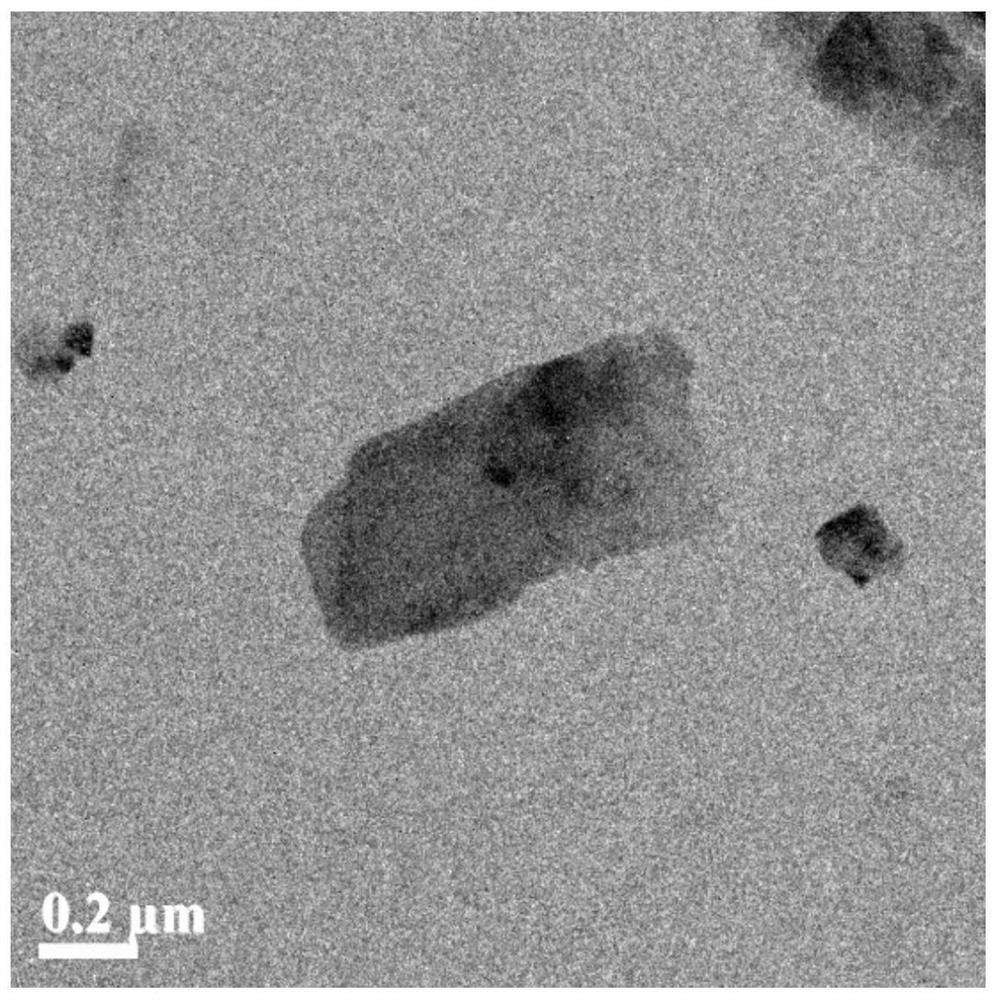

[0052] S1: Black phosphorus crystals are ground into black phosphorus powder in a mortar. Then the black phosphorus powder is dispersed in N-methyl-2-pyrrolidone (NMP), the mass volume ratio of black phosphorus powder and NMP is 0.5:1g / L, and ultrasonic 4-6h in ice bath probe (switch cycle: 5s / 5s). The obtained dispersion liquid was centrifuged at 3000 rpm for 10 min to obtain black phosphorus microflakes. The length×width×height of the black phosphorus microflakes was about 1.0 μm×0.4 μm×20 nm.

[0053] S2: In N,N-dimethylformamide, the black phosphorus microflakes prepared in S1 and azidopolyethylene glycol (N 3 -PEG) were mixed and added to a round-bottomed two-necked flask with a condensing device. The reactants were degassed and protected by repeated freezing in liquid nitrogen, vacuuming, and filling with nitrogen. After the liquid returned to room temperature, it was...

Embodiment 2

[0056] This embodiment has prepared a kind of black phosphorus material, and specific process is:

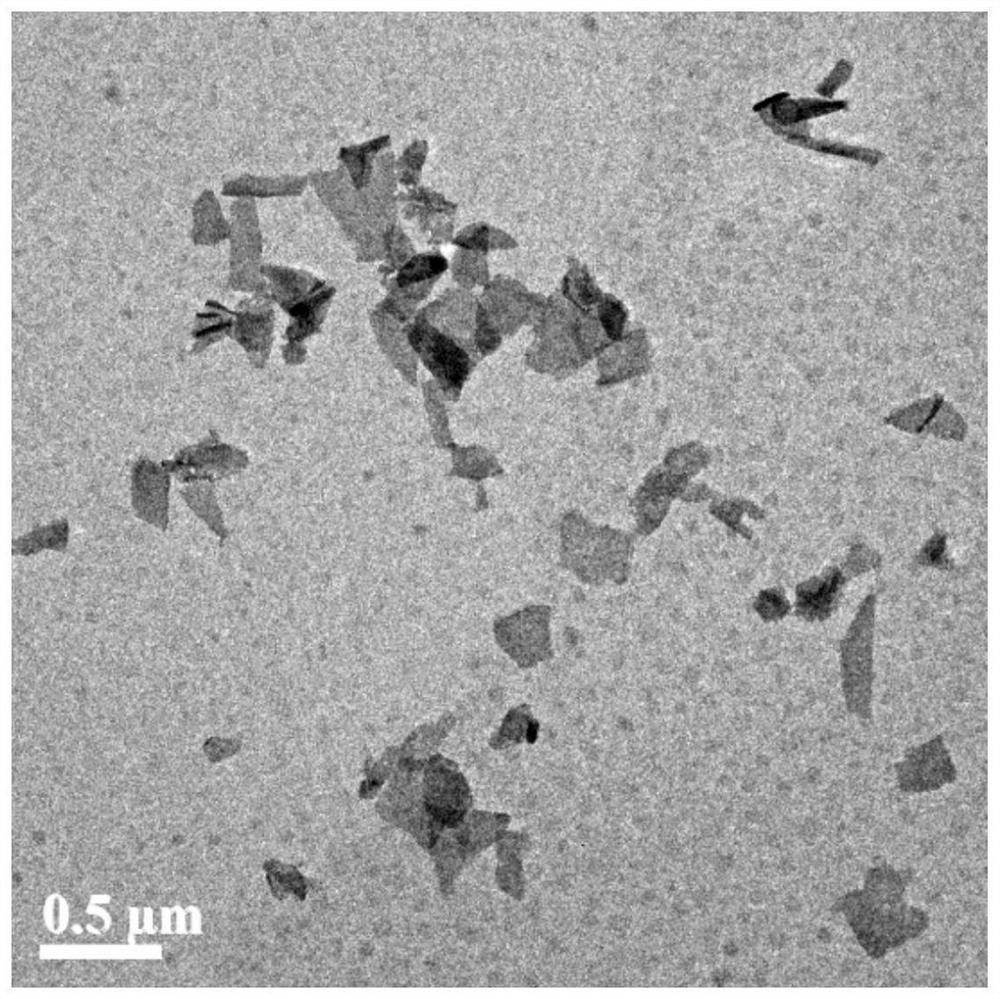

[0057] S1: Black phosphorus crystals are ground into black phosphorus powder in a mortar. Then disperse the black phosphorus powder in NMP, the mass volume ratio of black phosphorus powder and NMP is 1:1g / L, and ultrasonicate in the ice bath probe for 6-10h (on / off cycle: 5s / 5s). The obtained dispersion was centrifuged at 7000rpm for 20min to remove the unstripped large black phosphorus precipitate and collect the supernatant. The supernatant was centrifuged at 12000rpm for 20min to obtain black phosphorus nanosheets (BPNs), and the length×width×height of black phosphorus nanosheets (BPNs) was about 100nm×100nm×15nm.

[0058] S2: In N,N-dimethylformamide, black phosphorus nanosheets (BPNs) prepared in S1 and azidopolyethylene glycol (N 3 -PEG) were mixed and added to a round-bottomed two-necked flask with a condensing device. The reactants were degassed and protected by repea...

Embodiment 3

[0065] This embodiment has prepared a kind of black phosphorus material, and specific process is:

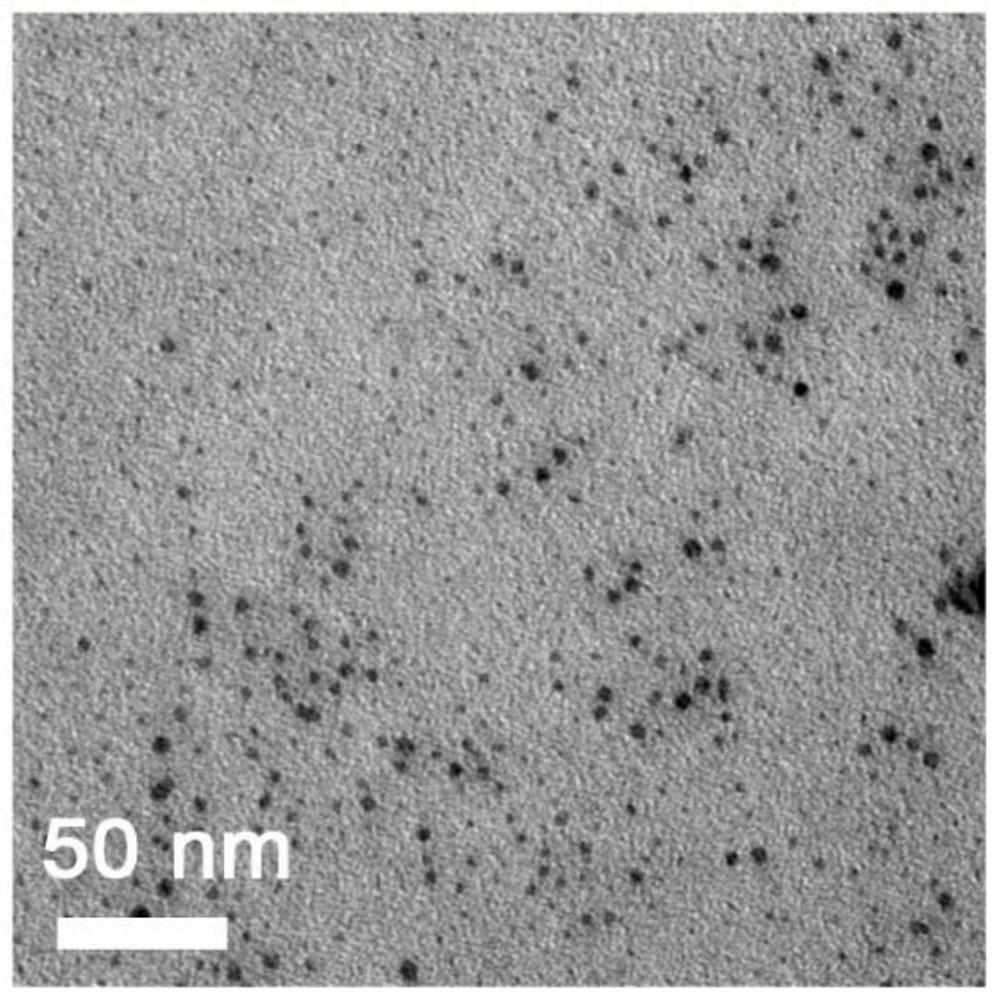

[0066] S1: Black phosphorus crystals are ground into black phosphorus powder in a mortar. Then disperse the black phosphorus powder in NMP, the mass volume ratio of black phosphorus powder and NMP is 1.5:1g / L, and ultrasonically in the ice bath probe for 6-10h (switch cycle: 5s / 5s), and then in a constant temperature water bath at 16°C Mid-ultrasound 8~10h (switching cycle: 5s / 5s). The resulting dispersion was centrifuged at 12,000 rpm for 20 min to remove unstripped large black phosphorus precipitates and collect the supernatant. The supernatant was centrifuged at 20000rpm for 20min to obtain black phosphorus quantum dots (BPQDs), and the length×width×height of the black phosphorus quantum dots (BPQDs) was about 5nm×5nm×2nm.

[0067] S2: In N,N-dimethylformamide, black phosphorus quantum dots (BPQDs) prepared in S1 and azidopolyethylene glycol (N 3 -PEG) were mixed and added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com