Anti-infection coating capable of realizing immediate construction in operation as well as preparation method and application of anti-infection coating

An anti-infection and coating technology, which is applied in coatings, pharmaceutical formulations, medical science, etc., can solve problems such as adjusting the content of anti-infection functional components, and achieve improved biocompatibility, wide application prospects, and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

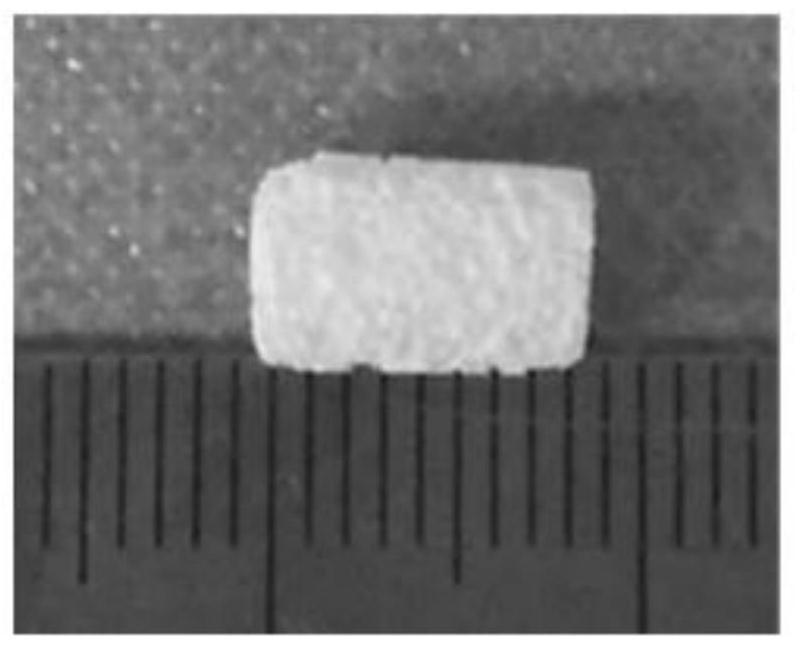

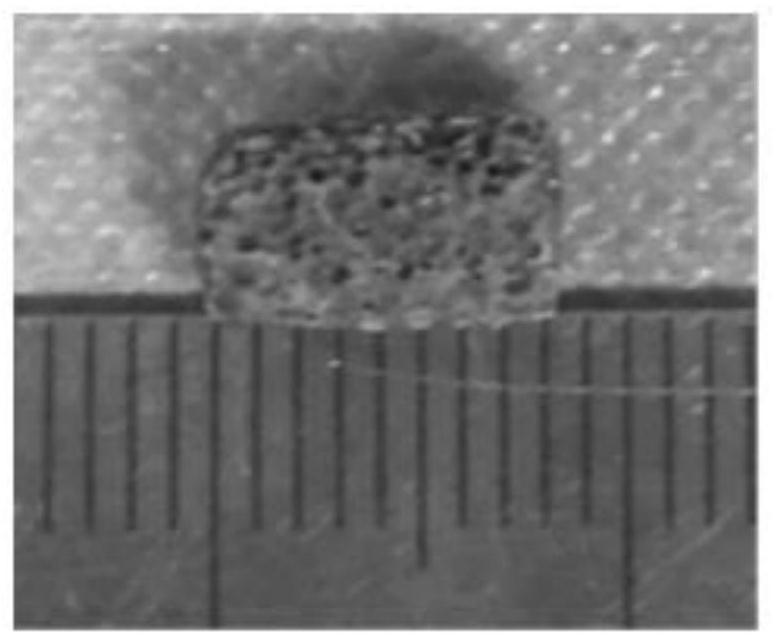

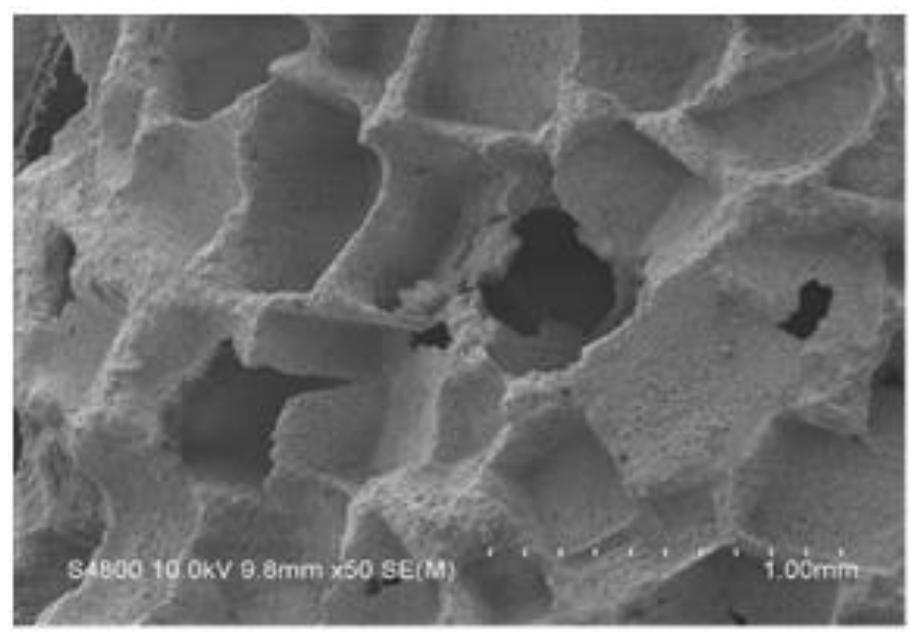

[0063] This embodiment provides a bone tissue implant, including a TCP porous artificial bone matrix structure (average pore size 100 μm, porosity 68%) and an anti-infection coating covering its surface that can realize immediate construction during surgery; The anti-infection coating includes an anti-infection drug coating (isoniazid, rifampicin, osteogenic growth peptide) on the surface of the matrix structure and a polymer material coating (chitosan) on the surface of the anti-infection drug coating. sugar (number average molecular weight 300kDa) and β-sodium glycerophosphate). Its preparation method is as follows:

[0064] (1) Place the TCP porous artificial bone matrix structure in an aqueous solution containing isoniazid (8%), rifampicin (4%), and osteogenic growth peptide (0.07%), and carry out vacuum adsorption under a negative pressure of 0.1MPa , until no air bubbles are generated around the artificial bone, and the surface of the TCP porous artificial bone matrix s...

Embodiment 2

[0067] This embodiment provides a bone tissue implant, comprising a TCP porous artificial bone matrix structure (average pore diameter 120 μm, porosity 75%) and an anti-infection coating covering its surface that can realize immediate construction during surgery; The anti-infection coating comprises an anti-infection drug coating (levofloxacin, osteogenic growth peptide) coated on the surface of the matrix structure and a polymer material coating (chitosan (number-average molecular weight 400kDa) coated on the surface of the anti-infection drug coating ) and β-sodium glycerophosphate). Its preparation method is as follows:

[0068] (1) Place the TCP porous artificial bone matrix structure in an aqueous solution containing levofloxacin (10%) and osteogenic growth peptide (0.07%), and carry out vacuum adsorption under a negative pressure of 0.2 MPa until no bubbles are generated around the artificial bone, and the TCP The surface of the porous artificial bone matrix structure i...

Embodiment 3

[0071] This embodiment provides a bone tissue implant, including New Zealand rabbit autologous ilium bone matrix structure (average pore diameter 80 μm, porosity 65%) and an anti-infection coating covering its surface that can realize immediate construction during surgery; The anti-infection coating includes an anti-infection drug coating (isoniazid, rifampicin, osteogenic growth peptide) coated on the surface of the matrix structure and a polymer material coating ( Chitosan (number average molecular weight 300kDa) and β-sodium glycerophosphate). Its preparation method is as follows:

[0072] (1) The New Zealand rabbit autologous ilium bone matrix structure was placed in an aqueous solution containing isoniazid (8%), rifampicin (4%), and osteogenic growth peptide (0.07%), under a negative pressure of 0.1MPa. Vacuum adsorption until no air bubbles are generated around the matrix structure, and anti-infective drug coating is obtained on the surface of the autologous ilium bone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com