Method for preparing silicon nitride ceramic from low-grade diatomite

A technology of silicon nitride ceramics and diatomite, which is applied in the field of silicon nitride ceramics preparation, can solve problems such as long nitriding time, and achieve the effects of low cost, simple process and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Step 2, preparation of silicon nitride green body

[0028] Mix the purified diatomite obtained in step 1 with 5wt% polyvinyl alcohol and 7wt% yttrium oxide evenly, place it in a mold, and press it into a silicon nitride green body with a pressing pressure of 15-30 MPa and a pressing time of 120-360s; preferably The pressing pressure is 25Mpa, and the pressing time is 240s;

[0029] Step 3, the preparation of silicon nitride ceramics

[0030] Put the silicon nitride body into the electric furnace, feed high-purity nitrogen (99.9%), first raise the temperature to 1100°C at a heating rate of 3-5°C / min, keep it warm for 2-3h, and then heat it at 8-10°C / min The heating rate is raised to 1420°C, the temperature is kept for 4-5 hours, and then the temperature is lowered to room temperature at a cooling rate of 5-10°C / min, and silicon nitride ceramics are obtained.

Embodiment 1

[0035] Step 1. Diatomaceous earth purification

[0036] Preheat low-grade diatomite to 500°C, keep it warm for 2 hours, add 2wt% dispersant to scrub, then pickle with 50wt% sulfuric acid, keep warm at 100°C for 2h, wash with water until neutral, suction filter, dry, and crush to Particle size ≤ 40 microns, to obtain purified diatomite; low-grade diatomite is SiO 2 Diatomite with a content greater than 75% and less than 85%; SiO in purified diatomite 2 Content ≥ 90%; dispersant is sodium hexametaphosphate;

[0037] Step 2, preparation of silicon nitride green body

[0038] The diatomite after the purification is mixed with 5wt% polyvinyl alcohol and 7wt% yttrium oxide, is placed in mold (disc ), the pressing pressure is 20MPa, and the pressing time is 120s;

[0039] Step 3, the preparation of silicon nitride ceramics

[0040] Put the silicon nitride body into the electric furnace, feed high-purity nitrogen (99.9%), first raise the temperature to 1100°C at a heating rate o...

Embodiment 2

[0042] Step 1. Diatomaceous earth purification

[0043] Preheat low-grade diatomite to 500°C, keep it warm for 2 hours, add 2wt% dispersant to scrub, then pickle with 50wt% sulfuric acid, keep warm at 100°C for 2h, wash with water until neutral, suction filter, dry, and crush to Particle size ≤ 40 microns, to obtain purified diatomite; low-grade diatomite is SiO 2 Diatomite with a content greater than 75% and less than 85%; SiO in purified diatomite 2 Content ≥ 90%; dispersant is sodium hexametaphosphate;

[0044] Step 2, preparation of silicon nitride green body

[0045] Mix the purified diatomite with 5wt% polyvinyl alcohol and 7wt% yttrium oxide evenly, place it in a mold (sheet 15×15×18mm), and press it into a silicon nitride green body, the pressing pressure is 25Mpa, and the pressing time is 240s ;

[0046] Step 3, the preparation of silicon nitride ceramics

[0047] Put the silicon nitride body into the electric furnace, feed high-purity nitrogen (99.9%), first rai...

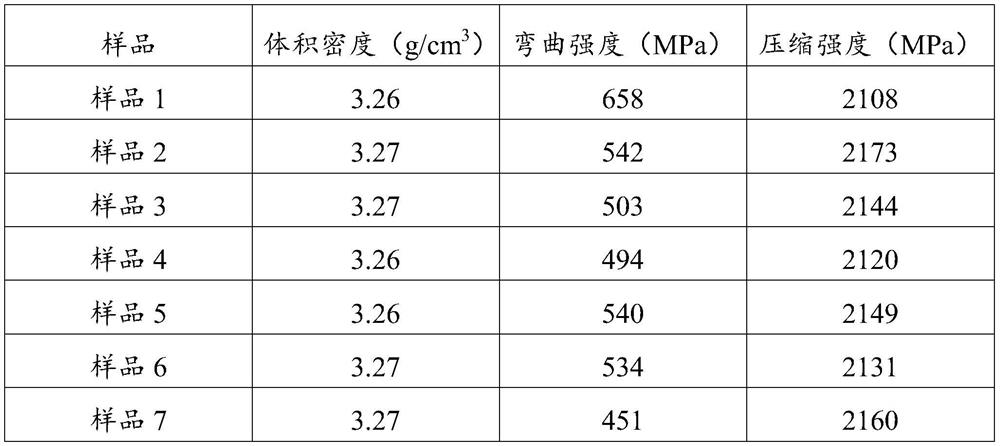

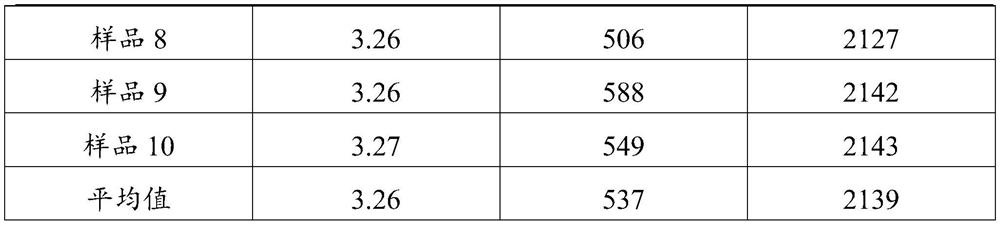

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com