Production process of water-milled carbonized bamboo summer sleeping mat

A technology of water-milled carbonized bamboo and production technology, which is applied in the direction of manufacturing tools, wood processing equipment, sugarcane machining, etc., can solve the problems of short retention time of antibacterial and anti-mite agents, poor persistence of anti-bacterial and anti-mite effects, etc., and achieve good gloss, The inner structure is tight and the effect of strong sweat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

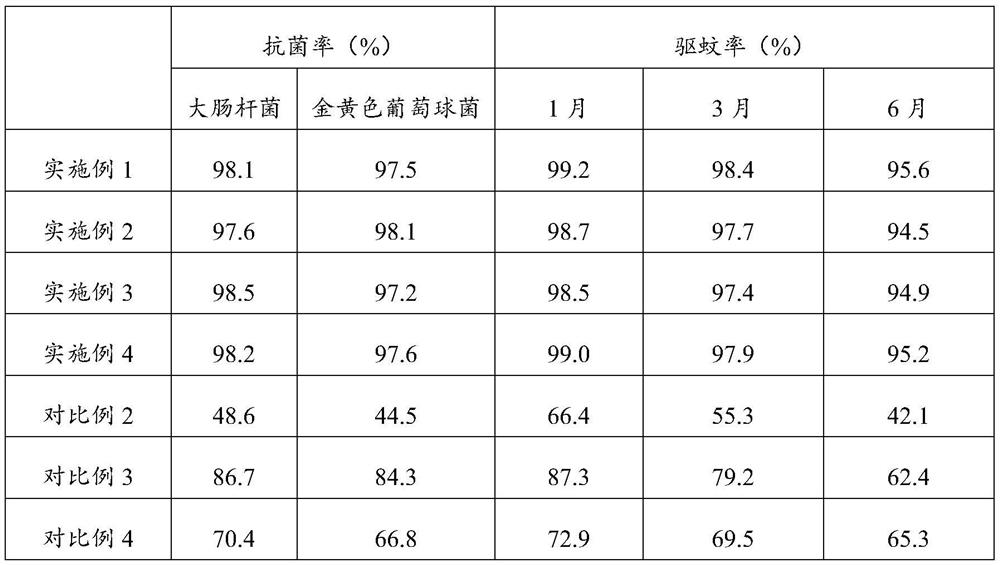

Examples

Embodiment 1

[0032] A production process of water-milled carbonized bamboo mat, comprising the following specific steps:

[0033] (1) Preparation of bamboo strips: select old winter bamboos that are at least 6 years old, and then process the bamboo into bamboo strips.

[0034] (2) Drying: Grinding the bamboo strips with water to remove bamboo green, dehydrating, and controlling the moisture content of the bamboo strips to be below 12%.

[0035] (3) Baking and carbonization: place the bamboo strips in a high-pressure carbonization furnace for carbonization treatment. The process of the carbonization treatment is as follows: the first step, the temperature of the high-pressure carbonization furnace is 120 ° C, the pressure is set to 3 MPa, carbonization The time is 60min; in the second step, the temperature of the high-pressure carbonization furnace is 250°C, the pressure is set to 2.0MPa, and the carbonization time is 1.5h; in the third step, the temperature of the high-pressure carbonizati...

Embodiment 2

[0040] A production process of water-milled carbonized bamboo mat, comprising the following specific steps:

[0041] (1) The preparation and drying steps of the bamboo strips are the same as in Example 1, specifically refer to Example 1.

[0042] (2) Baking and carbonization: place the bamboo strips in a high-pressure carbonization furnace for carbonization treatment. The process of the carbonization treatment is as follows: the first step, the temperature of the high-pressure carbonization furnace is 150 ° C, and the pressure is set to 1.5 MPa. The carbonization time is 80min; in the second step, the temperature of the high-pressure carbonization furnace is 230°C, the pressure is set to 3.5MPa, and the carbonization time is 1h; in the third step, the temperature of the high-pressure carbonization furnace is 320°C, the pressure is set to 4MPa, and the carbonization time is 30min .

[0043] (3) Impregnation treatment: After cleaning the carbonized bamboo strips, put them in a ...

Embodiment 3

[0046] A production process of water-milled carbonized bamboo mat, comprising the following specific steps:

[0047] (1) The preparation and drying steps of the bamboo strips are the same as in Example 1, specifically refer to Example 1.

[0048] (2) Baking and carbonization: place the bamboo strips in a high-pressure carbonization furnace for carbonization treatment. The process of the carbonization treatment is as follows: the first step, the temperature of the high-pressure carbonization furnace is 140 ° C, the pressure is set to 3 MPa, carbonization The time is 50min; in the second step, the temperature of the high-pressure carbonization furnace is 240°C, the pressure is set to 3MPa, and the carbonization time is 2h; in the third step, the temperature of the high-pressure carbonization furnace is 315°C, the pressure is set to 5MPa, and the carbonization time is 30min.

[0049] (3) Impregnation treatment: After cleaning the carbonized bamboo strips, put them in a water mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com