Preparation method of high-strength formaldehyde-free wood fiber board, fiber board and application

A wood fiberboard, high-strength technology, applied in applications, flat products, household components, etc., can solve the problems of complex process and ineffective production of formaldehyde-free fiberboard, and achieve the effect of increasing oxidation degree and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 (the concrete amount of the calcium chloride solution of wood waste residue, mixed solution and 10% needs to add)

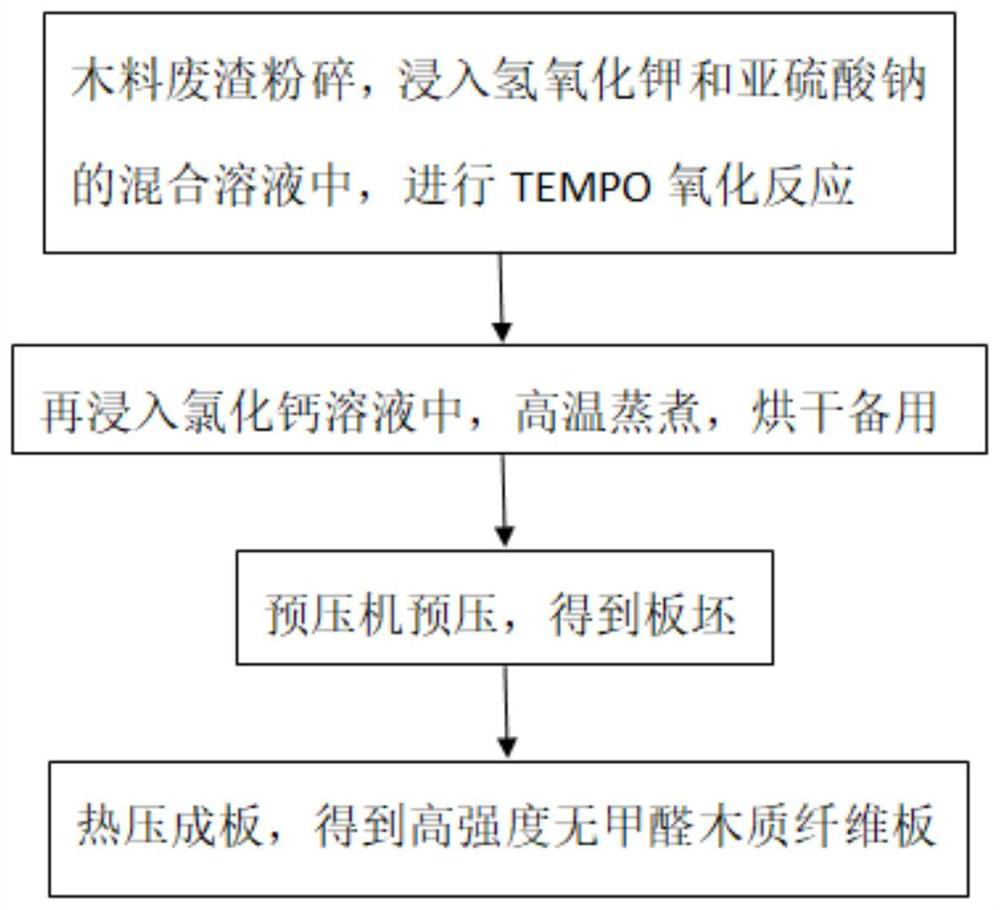

[0027] A preparation method of a high-strength formaldehyde-free wood fiber board, comprising the following steps:

[0028] 1) Wood pretreatment: Weigh 10g of poplar wood waste residue, crush it to 80 mesh, immerse the wood waste residue in 10ml of a mixed solution of potassium hydroxide and sodium sulfite for one immersion, immerse at 25°C for 5h, wherein potassium hydroxide is in the mixed solution The mass percentage is 0.8%, and the mass percentage of sodium sulfite in the mixed solution is 0.8%. After the impregnation is completed, rinse once with deionized water, and carry out the TEMPO oxidation reaction at 5°C for 1h, and immerse the wood waste residue in 10ml of 10% mass percentage of chlorine Carry out secondary impregnation in calcium chloride solution, immerse at 20°C for 5 hours, after the impregnation is completed, take out the w...

Embodiment 2

[0031] Embodiment 2 (the concrete amount of the calcium chloride solution of wood residue, mixed solution and 10% needs to add)

[0032] A preparation method of a high-strength formaldehyde-free wood fiber board, comprising the following steps:

[0033] 1) Wood pretreatment: Weigh 10g of poplar wood waste residue, crush it to 80 mesh, immerse the wood waste residue in 10ml of a mixed solution of potassium hydroxide and sodium sulfite for one immersion, immerse at 25°C for 5h, wherein potassium hydroxide is in the mixed solution The mass percentage is 0.5%, and the mass percentage of sodium sulfite in the mixed solution is 0.3%. After the impregnation is completed, rinse once with deionized water, and carry out the TEMPO oxidation reaction at 5°C for 1h, and immerse the wood waste residue in 10ml of 20% chlorine by mass. Carry out secondary impregnation in calcium chloride solution, immerse at 20°C for 5 hours, after the impregnation is completed, take out the wood waste residu...

Embodiment 3

[0036] Embodiment 3 (the specific amount of the calcium chloride solution of wood residue, mixed solution and 10% needs to add)

[0037] A preparation method of a high-strength formaldehyde-free wood fiber board, comprising the following steps:

[0038] 1) Wood pretreatment: Weigh 10g of poplar wood waste residue, crush it to 80 mesh, immerse the wood waste residue in 10ml of a mixed solution of potassium hydroxide and sodium sulfite for one immersion, immerse at 25°C for 5h, wherein potassium hydroxide is in the mixed solution The mass percentage is 2%, and the mass percentage of sodium sulfite in the mixed solution is 1%. After the impregnation is completed, rinse once with deionized water, and carry out TEMPO oxidation reaction at 5°C for 1h, and immerse the wood waste residue in 10ml of 25% chlorine by mass percentage. Carry out secondary impregnation in calcium chloride solution, immerse at 20°C for 5 hours, after the impregnation is completed, take out the wood waste res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com