Wet cobalt extraction raffinate waste liquid treatment method and prepared solution for ternary precursor preparation

A treatment method and raffinate technology, applied in chemical instruments and methods, improvement of process efficiency, inorganic chemistry, etc., can solve problems such as low nickel ion concentration, high equipment requirements, and dangerous high-voltage equipment, and achieve simple operation of the treatment process, Simple operation process, economical and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A treatment method for wet cobalt extraction raffinate waste liquid, said treatment method comprising the following steps:

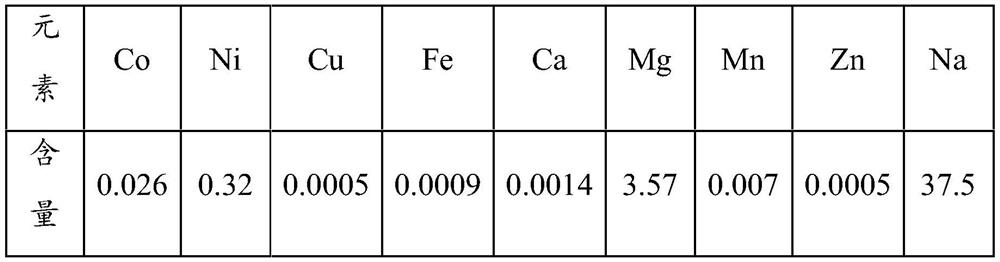

[0066] (1) Provide the waste raffinate liquid of cobalt extraction by wet method, and analyze the components of the waste raffinate liquid, as follows:

[0067]

[0068] Then select the above raffinate 1m 3 , control the temperature at 95°C, and use sodium carbonate to adjust the pH to 5.5. Add 13Kg of sodium fluoride according to the stoichiometric ratio of 100% (the total amount of calcium and magnesium), react for 2.5 hours, and filter to obtain the magnesium-removed liquid.

[0069] After testing, the composition of the liquid after magnesium removal is as follows:

[0070] element co Ni Cu Fe Ca Mg mn Zn Na content 0.025 0.29 0.0004 0.0007 0.001 0.1 0.007 0.0005 44

[0071] (2), select 500L of the above-mentioned demagnesium solution, and slowly add saturated sodium sulfide solution thereinto...

Embodiment 2

[0088] A treatment method for wet cobalt extraction raffinate waste liquid, said treatment method comprising the following steps:

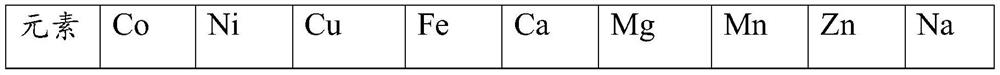

[0089] (1) Provide the waste raffinate liquid of cobalt extraction by wet method, and analyze the components of the waste raffinate liquid, as follows:

[0090]

[0091] The magnesium content of this effluent is low, so there is no need to use fluoride to remove magnesium.

[0092] (2), select 500L of the above-mentioned solution, and slowly add saturated sodium sulfide solution thereinto. The end point of the reaction is to take an appropriate amount of supernatant in the reaction system, add saturated sodium sulfide solution to the supernatant, and no black precipitate occurs after stirring. After reaching the end of the reaction, stop adding the saturated sodium sulfide solution, continue the reaction for 15 minutes, and filter to obtain cobalt-nickel-rich slag.

[0093] After testing, the composition of the cobalt-nickel enriched slag is ...

Embodiment 3

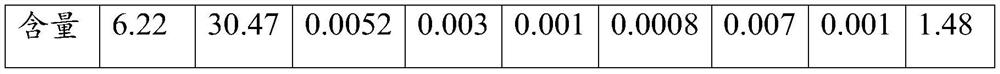

[0103] (1) Provide the waste raffinate liquid of cobalt extraction by wet method, and analyze the components of the waste raffinate liquid, as follows:

[0104]

[0105] Then select the above raffinate 1m 3 , control the temperature at 95°C, and use sodium carbonate to adjust the pH to 5.5. Add 2.7Kg of sodium fluoride according to the stoichiometric ratio of 90% (the total amount of calcium and magnesium), react for 2.5 hours, and filter to obtain the magnesium-removed solution.

[0106] After testing, the composition of the liquid after magnesium removal is as follows:

[0107] element co Ni Cu Fe Ca Mg mn Zn Na content 0.021 0.43 0.0007 0.0008 0.0006 0.15 0.008 0.0005 41

[0108] (2), select 500L of the above-mentioned solution, and slowly add saturated sodium sulfide solution thereinto. The end point of the reaction is to take an appropriate amount of supernatant in the reaction system, add saturated sodium sulfide solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com