Purification treatment system for tail water of sewage plant and construction method of purification treatment system

A technology for purification treatment and sewage treatment plant, which is applied to the purification treatment system of tail water of sewage treatment plant and its construction field, which can solve the problems of secondary pollution, high investment and operation cost, and unsatisfactory purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

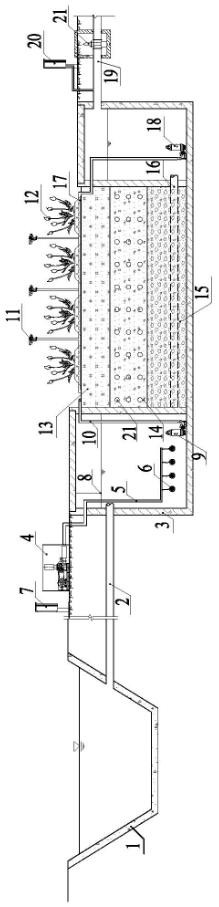

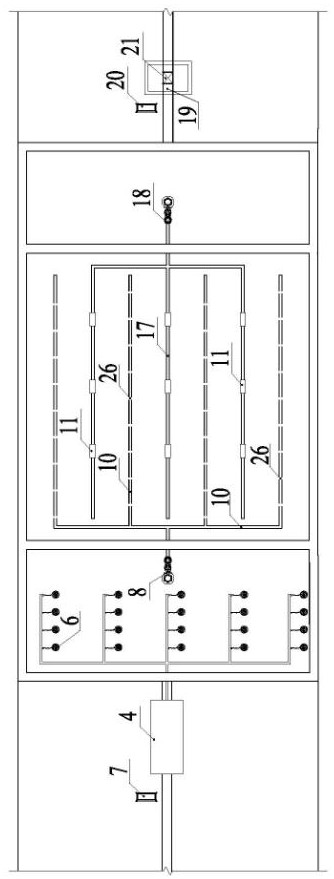

Embodiment 1

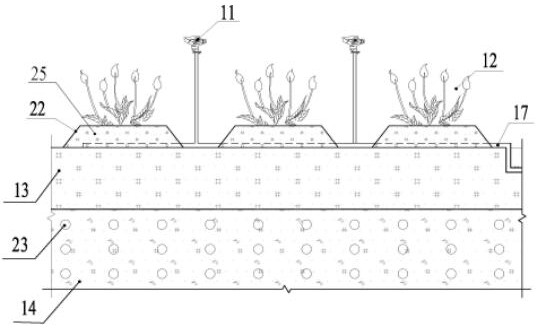

[0046] Such as figure 2 As shown, the aeration tubes 5 are arranged side by side with an interval of 1-3m, and an aeration disc 6 is hung under the aeration tubes. The distance between adjacent aeration discs 6 is 50-100 cm, and the size of the aeration discs 6 is 30-60 cm. The first water distribution pipe 10 and the second water distribution pipe 17 are arranged at intervals with a distance of 3-5 m. The first water distribution pipe 10 and the second water distribution pipe 17 are made of PVC or PE. The nozzles 11 are connected through the second water distribution pipe 17, and the nozzles 11 are arranged at intervals of 5-10m.

[0047] The cross section of the ridge 25 is trapezoidal, with a top width of 20-50cm.

[0048] The wetland plants 12 adopt floating plants, floating leaf plants or emergent plants.

[0049] The thickness of the rooting soil layer 13 is 20-30 cm, which meets the growth requirements of plants. The thickness of the volcanic rock granular layer 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com