High-water-permeability blue glass based on float process and production method of high-water-permeability blue glass

A production method and float process technology, applied in the field of high-permeability blue glass and its production, can solve the problems of unstable source, increased cost of high-permeability glass, complicated process, etc., achieve good color appearance, prolong service life, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

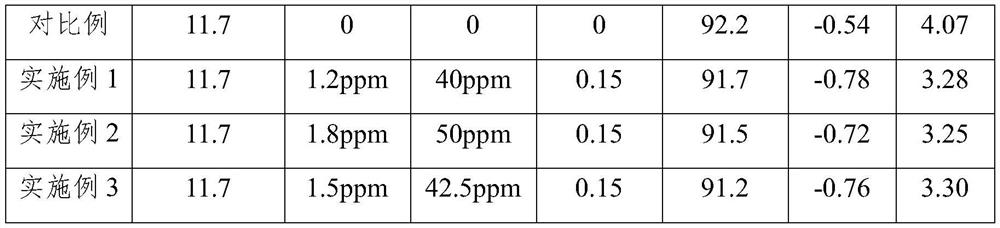

Embodiment 1

[0052] This embodiment provides a method for producing highly water-permeable blue glass based on the float process, the production method comprising the following steps:

[0053] Step S1, weighing float glass production raw materials, said raw materials contain a predetermined amount of quartz sand; based on the glass production raw materials, weighing predetermined amounts of cobalt trioxide powder and manganese dioxide powder as colorants, The amount of dicobalt trioxide is 1.2 ppm of the total mass of raw materials for glass production, and the amount of manganese dioxide powder is 40 ppm of the total mass of raw materials for glass production.

[0054] The content of impurities in the cobalt trioxide powder and manganese dioxide powder is less than 0.2 wt%.

[0055] The raw materials for glass production also include other raw materials and glass clinker, and the total iron content is not more than 300ppm.

[0056] Step S2, mixing the cobalt trioxide powder and manganese...

Embodiment 2

[0064] This embodiment provides a method for producing highly water-permeable blue glass based on the float process, the production method comprising the following steps:

[0065] Step S1, weighing float glass production raw materials, based on the glass production raw materials, weighing a predetermined amount of dicobalt trioxide powder and manganese dioxide powder, as colorants, the amount of dicobalt trioxide is the total amount of glass production raw materials The mass is 1.8ppm, and the consumption of the manganese dioxide powder is 50ppm of the total mass of raw materials for glass production.

[0066] The content of impurities in the cobalt trioxide powder and manganese dioxide powder is less than 0.2 wt%.

[0067] The raw materials for glass production also include other raw materials and glass clinker, and the total iron content is not more than 300ppm.

[0068] Step S2, mixing the cobalt trioxide powder and quartz sand in a mass ratio of 1:999, using a three-stage...

Embodiment 3

[0077] This embodiment provides a method for producing highly water-permeable blue glass based on the float process, the production method comprising the following steps:

[0078] Step S1, weighing float glass production raw materials, said raw materials contain a predetermined amount of quartz sand; based on the glass production raw materials, weighing predetermined amounts of cobalt trioxide powder and manganese dioxide powder as colorants, The amount of dicobalt trioxide is 1.5ppm of the total mass of raw materials for glass production, and the amount of manganese dioxide powder is 42.5ppm of the total mass of raw materials for glass production.

[0079] The content of impurities in the cobalt trioxide powder and manganese dioxide powder is less than 0.2 wt%.

[0080] The raw materials for glass production also include other raw materials and glass clinker, and the total iron content is not more than 300ppm.

[0081] Step S2, mixing the cobalt trioxide powder and quartz sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com