Stainless steel coloring liquid and coloring method

A technology of stainless steel and coloring liquid, applied in the direction of anodic oxidation, etc., can solve the problems of cancer, vanadium poisoning, etc., and achieve the effects of good environmental performance, low temperature, good wear resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the coloring liquid is preferably as follows: respectively dissolve the weighed sodium hydroxide, trisodium phosphate and sodium nitrate with a small amount of distilled water, add distilled water to the specified volume after mixing, and make the concentration of each solute reach the above range.

[0032] The invention also discloses a stainless steel coloring method, comprising the following steps:

[0033] The pretreated stainless steel sample is used as the positive electrode, and the lead plate is used as the negative electrode, and the electrolytic coloring is carried out in the stainless steel coloring solution described in the above technical scheme.

[0034] According to the present invention, a pretreated stainless steel sample is firstly provided. The stainless steel is preferably 316, 304 or SUS304 stainless steel. The pretreatment preferably includes in sequence: chemical degreasing, electrolytic polishing and activation. The me...

Embodiment 1

[0045]After chemical degreasing, electropolishing and activation treatment, the 1Cr18 stainless steel is put into the prepared electrolytic coloring solution of the invention as an anode, and the cathode is a lead plate.

[0046] The electrolyte composition is: sodium hydroxide 200g / L, trisodium phosphate 8g / L, sodium nitrate 10g / L;

[0047] The operating parameters of electrolytic coloring are: anode current density 0.3A / dm 2 , the temperature of the water bath is 50° C., and the time is 10 minutes.

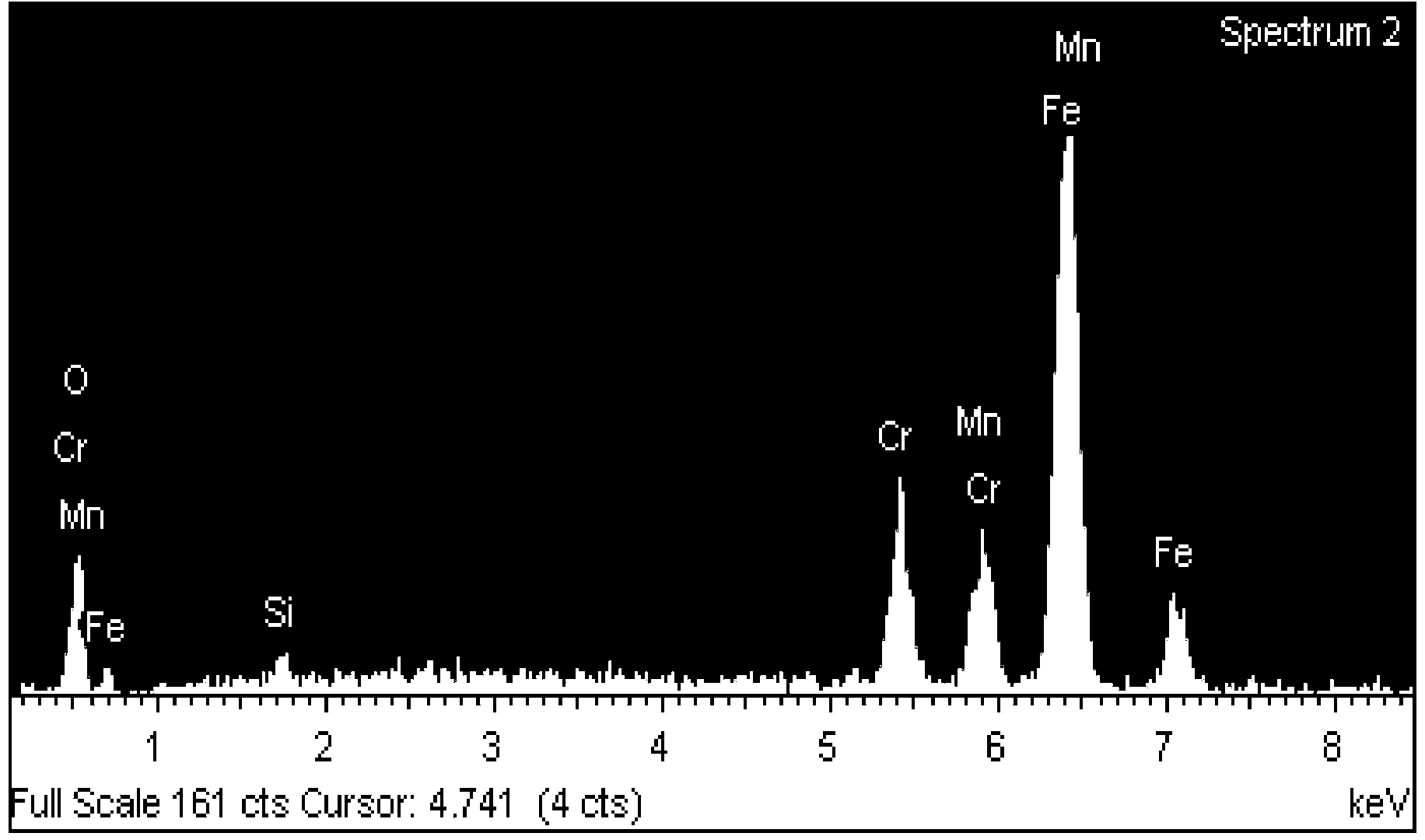

[0048] The obtained coloring film is golden yellow, and the surface EDS energy spectrum analysis after electrolytic coloring treatment is as follows: figure 1 As shown, the result shows that its surface layer composition is: 55.68Fe10.06Cr10.04Mn1.66Si22.56O (atomic percentage).

Embodiment 2

[0050] The Japanese SUS304 stainless steel sheet is used, after chemical degreasing, electrolytic polishing and activation treatment, it is put into the prepared electrolytic coloring solution of the invention as an anode, and the cathode is a lead plate.

[0051] Electrolytic coloring process parameters are: sodium hydroxide 500g / L, sodium nitrate 8g / L, potentiostat control voltage 2.2V, water bath temperature 100°C, time 15 minutes.

[0052] The obtained colored film is also golden yellow, and the colored film is smooth, bright and uniform in color.

[0053] The test results prove that the coloring film can withstand the back and forth friction of rubber with a force of 200g for more than 70 cycles without discoloration, and can withstand immersion in 3.5% sodium chloride solution for 480 hours without discoloration.

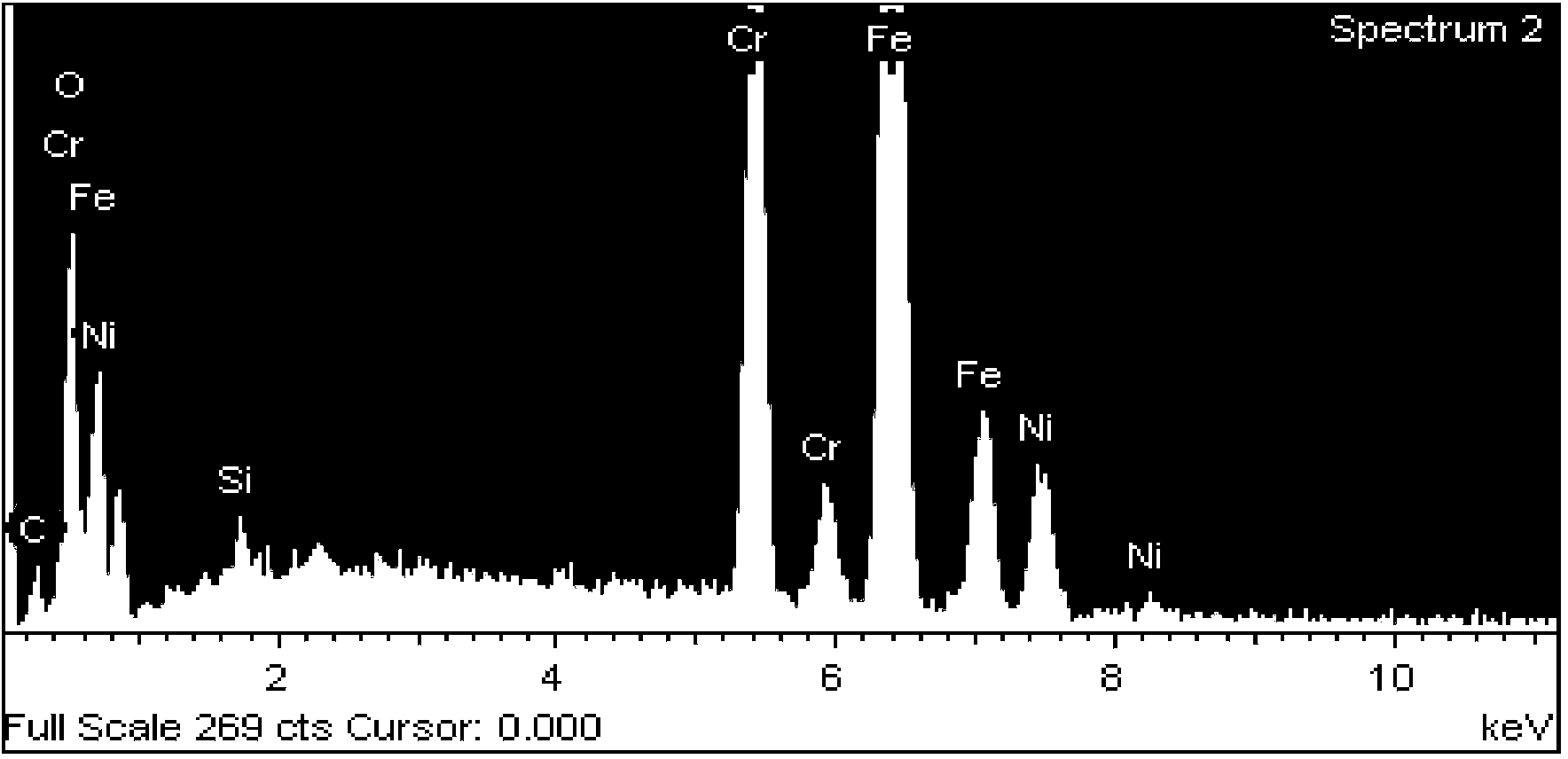

[0054] figure 2 The EDS energy spectrum analysis of the surface after the coloring treatment shows that the surface layer composition is: 45.64Fe13.70Cr6.74...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Anode current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com