Fluorosilicone polymer capable of being subjected to UV light and heat curing, preparation method thereof and coating

A technology of fluorosilicon polymer and heat curing, which is applied in the direction of coating, etc., can solve the problems of long cycle, short operation cycle temperature, and unapplicable silicone polymer coating, etc., to achieve short curing cycle, good solvent resistance, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

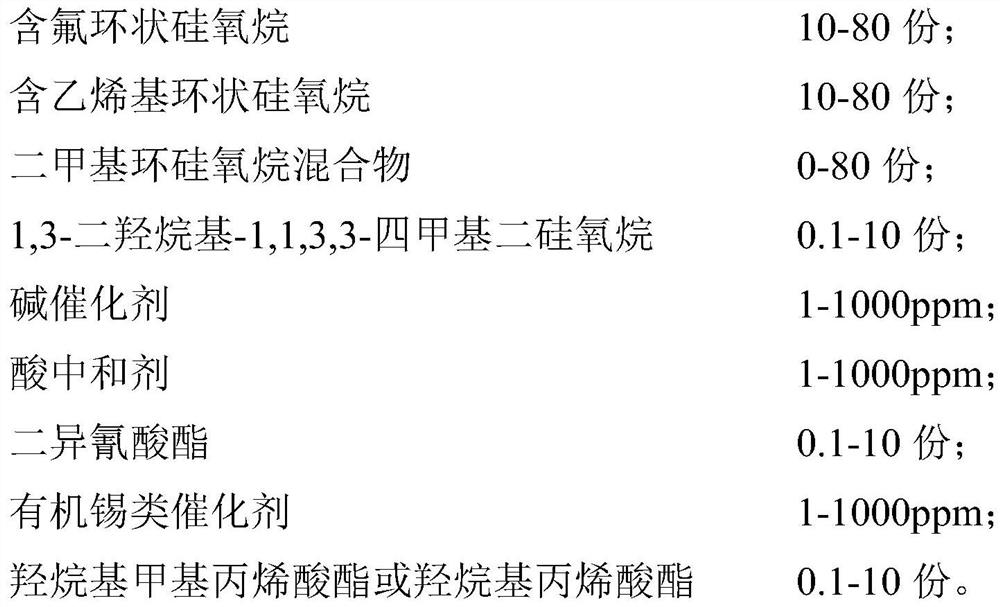

Method used

Image

Examples

Embodiment 1

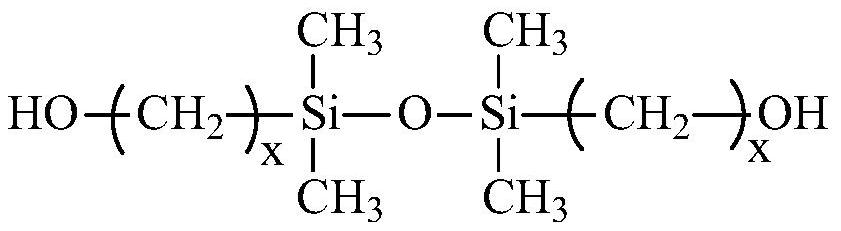

[0036] 1mol of trifluoropropylmethylcyclotrisiloxane, 0.1mol of trimethyltrivinylcyclotrisiloxane, 1,3-dihydroxypropyl-1,1,3,3-tetramethyldisiloxane Add 0.01mol of oxane into the reactor, dehydrate at 45°C for 1h, then add 20ppm tetramethylammonium hydroxide silicon alkoxide, polymerize at 45°C for 1h, then add 200ppm of fluorine-containing silicon-based phosphate for neutralization for 1h . Then the temperature was raised to 180°C, the pressure was reduced to above -0.09MPa, and the low boiling was removed under reduced pressure for 1 hour. Then lower the temperature to 30-90°C, add 0.005 mol of toluene diisocyanate, 100 ppm of dibutyltin dilaurate, and 0.01 mol of hydroxyethyl methacrylate, and react for 24 hours to obtain a colorless and transparent dual-curable fluorosilicon polymer.

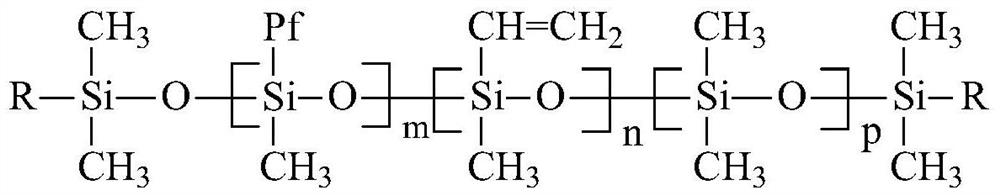

[0037] The molecular structure of the obtained fluorosilicon polymer is:

[0038]

[0039] Mix the prepared fluorosilicon polymer and photoinitiator 1173 evenly and apply it on the PET ...

Embodiment 2

[0043] Add 1mol of trifluoropropylmethylcyclotrisiloxane, 0.1mol of trimethyltrivinylcyclotrisiloxane, 0.5mol of DMC, 1,3-dihydroxypropyl-1,1,3,3-tetra Add 0.01mol of methyldisiloxane into the reactor, dehydrate at 45°C for 1h, then add 20ppm tetramethylammonium hydroxide silicon alkoxide, polymerize at 45°C for 1h, then add fluorine-containing silicon-based phosphate 200ppm and 1h. Then the temperature was raised to 180°C, the pressure was reduced to above -0.09MPa, and the low boiling was removed under reduced pressure for 1 hour. Then lower the temperature to 30-90°C, add 0.005 mol of toluene diisocyanate, 100 ppm of dibutyltin dilaurate, and hydroxyethyl methacrylate (0.01 mol), and react for 24 hours to obtain a colorless and transparent dual-curable fluorosilicon polymer.

[0044] The molecular structure of the obtained fluorosilicon polymer is:

[0045]

[0046] Mix the prepared fluorosilicon polymer and photoinitiator 1173 evenly and apply it on the PET film. Sil...

Embodiment 3

[0050]Add 1mol of trifluoropropylmethylcyclotrisiloxane, 0.1mol of trimethyltrivinylcyclotrisiloxane, 0.5mol of DMC, 1,3-dihydroxypropyl-1,1,3,3-tetra Add 0.01mol of methyldisiloxane into the reactor, dehydrate at 45°C for 1h, then add 20ppm tetramethylammonium hydroxide silicon alkoxide, polymerize at 45°C for 1h, then add fluorine-containing silicon-based phosphate (200ppm), neutralize for 1h. Then the temperature was raised to 180°C, the pressure was reduced to above -0.09MPa, and the low boiling was removed under reduced pressure for 1 hour. Then lower the temperature to 30-90°C, add 0.005 mol of hexamethyl diisocyanate, 100 ppm of dibutyltin dilaurate, and 0.01 mol of hydroxyethyl methacrylate, and react for 24 hours to obtain a colorless and transparent dual-curable fluorosilicon polymer.

[0051] The molecular structure of the obtained fluorosilicon polymer is:

[0052]

[0053] Mix the prepared fluorosilicon polymer and photoinitiator 1173 evenly and apply it on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com