Anti-rust alkyd primer

A primer and alkyd technology, applied in the direction of anti-corrosion coatings, coatings, polyester coatings, etc., can solve problems such as polluted water quality, serious injuries to construction personnel, and difficult to cure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

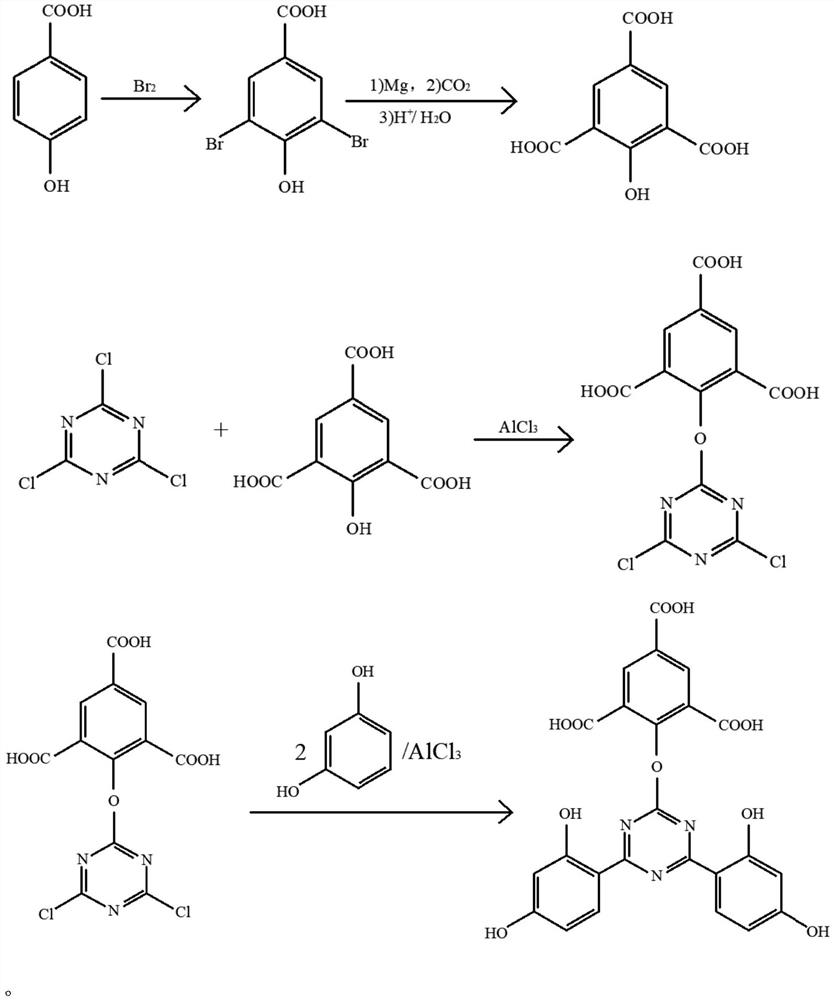

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of Alkyd Primer

[0025] The composition of the formula used to prepare the alkyd primer in this example is shown in Table 2. By selecting different types of polybasic acids to participate in the preparation of the alkyd primer, 4 groups of treatment groups are constructed. The specific marks and corresponding setting methods are as follows: : Treatment IA, using compound I as the polybasic acid in the formula provided in Table 2, participating in the preparation of alkyd primer; Treatment IIA, using 2,4,6-tris(4-carboxyphenyl)-1,3,5 - Triazine participates in the preparation of alkyd primer as the polybasic acid in the formula provided in Table 2; handles IIIA, adopts trimesic acid as the polybasic acid in the formula provided in Table 2, and participates in the preparation of alkyd primer; IVA, using phthalic anhydride as the polyacid in the formulation provided in Table 2, was involved in the formulation of the alkyd primer.

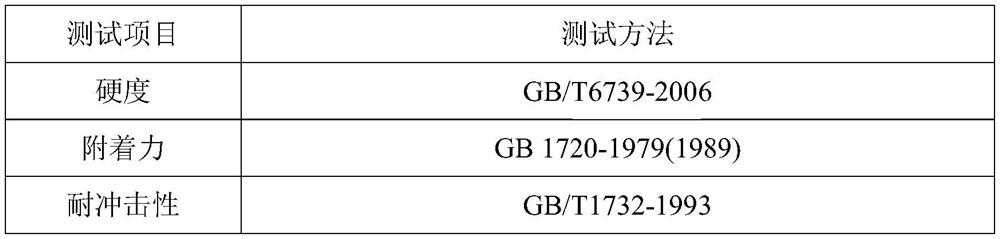

[0026] Table 2 present e...

Embodiment 2

[0046] In this embodiment, based on the alkyd primer formula and paint-making operation steps adopted in the treatment IA of Example 1, three groups of treatment groups in this example were constructed in the following manner: treatment IB, the alkyd primer formula used and The paint-making operation steps are strictly consistent with the treatment IA of Example 1; for the treatment IIB, the alkyd primer is prepared with reference to the formula and paint-making operation steps adopted in the treatment IA of Example 1, and the difference between the composition of the treatment IA is that the The xylene of the same mass fraction replaces DMF and is used to prepare the component A used in the process of preparing the paint; for treatment IIIB, refer to the formula and paint making operation steps adopted in the treatment IA of Example 1 to prepare the alkyd primer, and the treatment IA The only difference in composition is that DMF is replaced by butyl acetate in the same mass f...

Embodiment 3

[0052] 1. Preparation of Alkyd Primer

[0053] In this embodiment, based on the alkyd primer formula and paint-making operation steps adopted in the treatment IA of Example 1, three groups of treatment groups in this example were constructed in the following manner: treatment IC, the alkyd primer formula used and The paint-making operation steps are strictly consistent with the treatment IA of Example 1; for the treatment IIC, the alkyd primer is prepared with reference to the formula and paint-making operation steps adopted in the treatment IA of Example 1, and the difference from the composition of the treatment IA is only that the The ferric nitrate of 10.2 parts (mass parts) replaces the ammonium molybdate of 8.3 parts (mass parts) in the original formula, is used for the component A that applies in the preparation paint process; Process III C, refer to the processing IA institute of embodiment 1 The adopted formula and paint-making operation steps are used to prepare the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap