Electromagnetic thermal coupling and thermoelectric chemical oxidation equipment

An electromagnetic thermal coupling, thermoelectrochemical technology, applied in the direction of anodic oxidation, electrolytic coating, electrolytic process, etc., can solve the problems of poor fluidity of electrolyte, decrease of solution resistance, influence of ceramic layer performance, etc., to increase temperature range, cooling power The effect of reducing power consumption and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

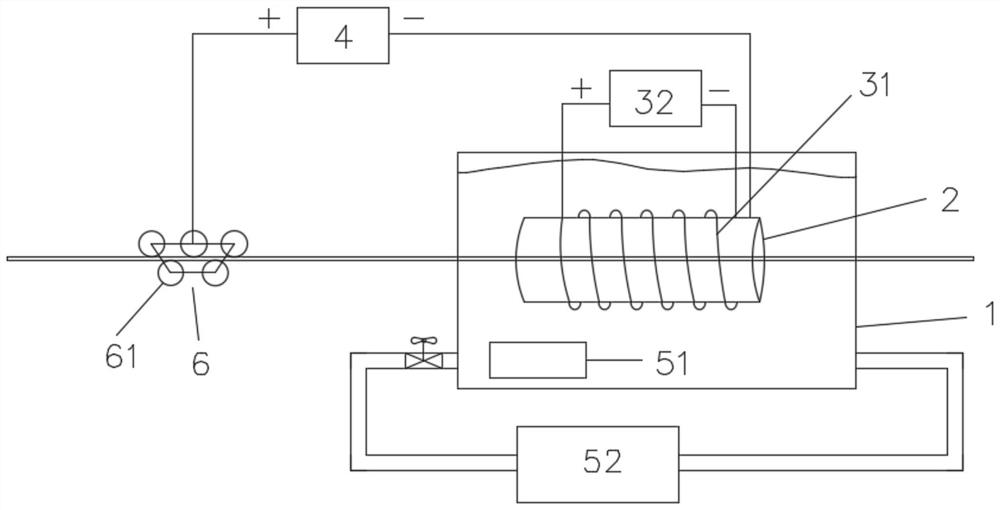

[0036] A device for thermoelectrochemical oxidation coupled with electromagnetic heat, such as figure 1 As shown, it includes: electrolytic cell 1, electrolytic cell 2, electromagnetic thermal coupling part 3, thermoelectrochemical oxidation power supply 4 and temperature control system 5, the electrolytic cell 2 is inside the electrolytic cell 1, and the electrolytic cell 2 is a hollow cylinder , the electrolytic cell 1 is used to contain the electrolyte, the electrolyte overflows the electrolytic cell 2, the electromagnetic thermal coupling part 3 is connected with the electrolytic cell 2, and the electromagnetic thermal coupling part 3 is used to control the directional movement of the charged particles in the electrolytic cell 2 through a magnetic field, The electromagnetic thermal coupling part 3 is composed of a helical coil 31 and a current source 32. The helical coil 31 is formed by helically winding an insulated wire on the outer wall of the electrolytic cell 2. The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com