Method and system for preparing steel strand-FRP composite bar

A technology of steel strands and composite bars, used in manufacturing tools, heat treatment equipment, coatings, etc., can solve the problems of acid corrosion, do not allow cracks, damage, etc., to meet the requirements of high temperature environment, prevent resin leakage, and protect a wide range of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

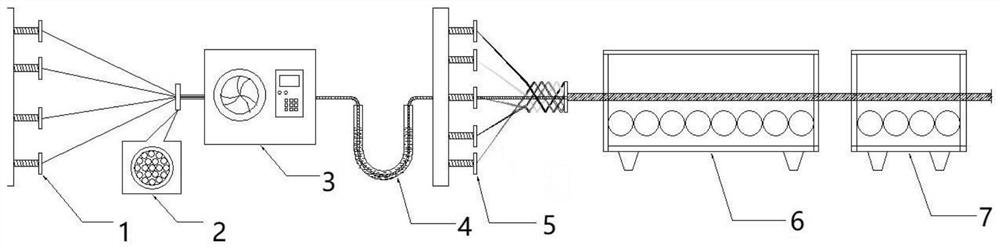

[0027] The invention provides a kind of preparation method of steel strand-FRP composite reinforcement, comprises the following steps:

[0028] Stranding the steel wires to obtain steel strands;

[0029] placing the steel strand in a resin solution and impregnating it to obtain a resin-coated steel strand;

[0030] FRP fiber bundles are wrapped on the surface of the resin-coated steel strands, followed by heating and curing and cooling and shrinking to obtain steel strand-FRP composite bars.

[0031] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known to those skilled in the art.

[0032] The invention twists the steel wires to obtain steel strands. In the present invention, the steel wire is preferably a scored steel wire. In the present invention, the diameter of the steel wire is preferably 2.5-6 mm; the strength is preferably 1570 MPa and above.

[0033] In the present invention, the preparation me...

Embodiment 1

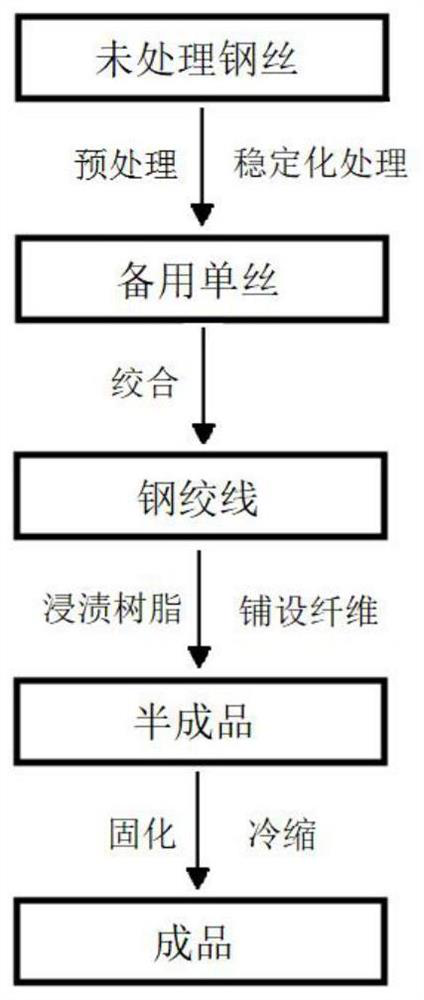

[0062] use as figure 2 The shown process flow chart prepares steel strand-FRP composite bars:

[0063] Select a scored steel wire with a diameter of 5mm, soak the untreated steel wire in an aqueous hydrogen peroxide solution with a mass fraction of 15%, control the temperature at 25°C, stir slowly during soaking, and soak for 45 minutes. Stop soaking when bubbles appear, and after soaking, dry the steel wire naturally at room temperature until there is no moisture on the surface to obtain the pretreated steel wire;

[0064] Put the pretreated steel wire in a muffle furnace, raise the temperature from room temperature to 450°C at a rate of 8°C / min, then rise to 850°C at a rate of 12°C / min, and keep it warm for 1min; after treatment, Cool to room temperature to obtain a stabilized steel wire;

[0065] The stabilized steel wire is subjected to cold-drawing monofilament to obtain a cold-drawn steel wire; the drawing speed of the cold-drawn monofilament is 50mm / min, and the cold...

Embodiment 2

[0076] Select a scored steel wire with a diameter of 5mm, soak the untreated steel wire in an aqueous hydrogen peroxide solution with a mass fraction of 15%, control the temperature at 25°C, stir slowly during soaking, and soak for 45 minutes. Stop soaking when bubbles appear, and after soaking, dry the steel wire naturally at room temperature until there is no moisture on the surface to obtain the pretreated steel wire;

[0077] Place the pretreated steel wire in a muffle furnace, raise the temperature from room temperature to 430°C at a rate of 6°C / min, then rise to 830°C at a rate of 12°C / min, and keep it warm for 1min; after treatment, Cool to room temperature to obtain a stabilized steel wire;

[0078] The stabilized steel wire is subjected to cold-drawing monofilament to obtain a cold-drawn steel wire; the drawing speed of the cold-drawn monofilament is 60mm / min, and the cold drawing rate is 1%;

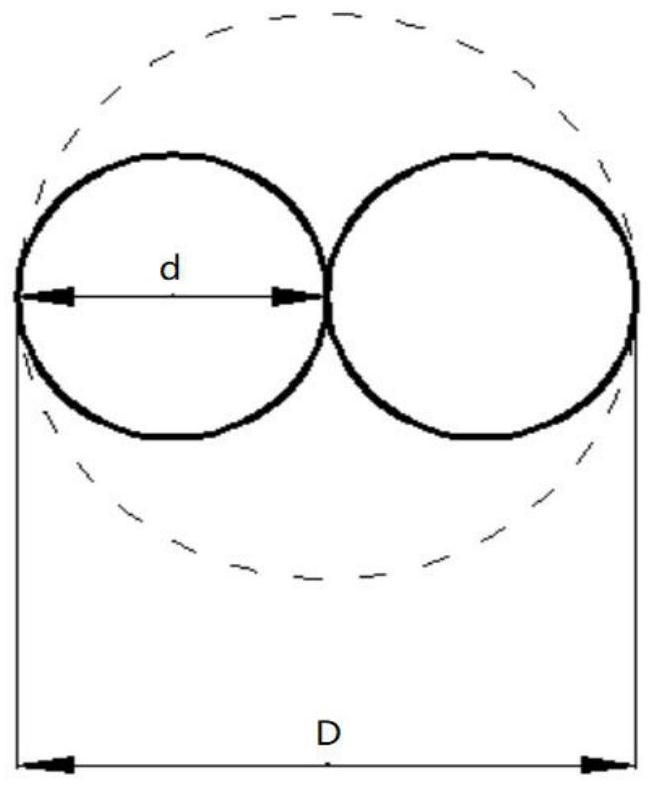

[0079] The three cold-drawn steel wires as Figure 4 The arrangement sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com