NiO nanoparticle gas sensor element based on Cr doping, preparation method and application thereof

A gas sensor and nanoparticle technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of limited gas sensing performance, low sensitivity, poor selectivity, etc., and achieve the effect of improving gas sensing performance, low cost, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1. Preparation of a gas sensor element using NiO nanoparticles as a gas-sensitive material

[0068] Prepare a gas sensor element using NiO nanoparticles as a gas-sensitive material according to the following steps:

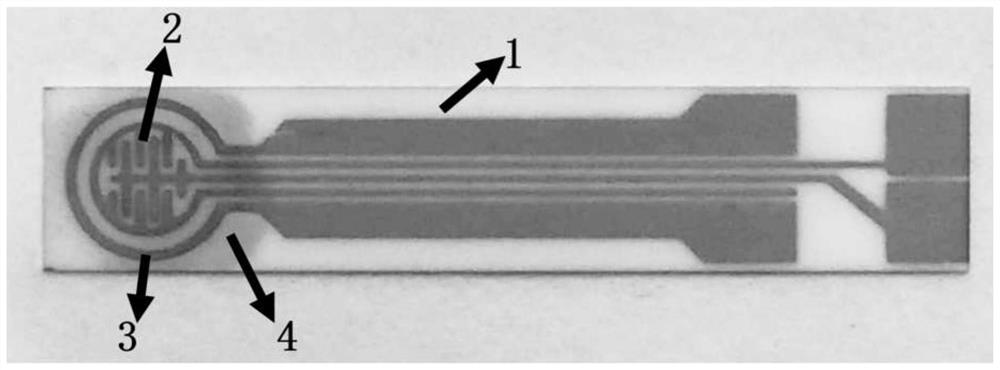

[0069] (1) Ultrasonic cleaning with water, ethanol and acetone in sequence figure 1 The surface of the flat substrate shown is dried at 60°C;

[0070] (2) Add 30mL deionized water, 0.475g nickel chloride hexahydrate, 0.28g hexamethylenetetramine into a 50mL beaker, stir for 15min, add 2mL ethanolamine, and continue stirring for 20min to obtain a mixed solution. Under hydrothermal reaction for 8 hours, after cooling to room temperature, the NiO precursor was obtained by centrifugal washing and drying;

[0071] (3) The NiO precursor prepared in step (2) is then calcined in a muffle furnace. The calcination conditions are as follows: from room temperature to 500°C at a heating rate of 5°C / min, kept for 3h, and then naturally cooled to At room temper...

Embodiment 2

[0075] Embodiment 2, preparing the gas sensor element with 15% Cr-NiO nanoparticles as the gas sensitive material

[0076] Prepare a gas sensor element using 15% Cr-NiO nanoparticles as a gas-sensing material according to the following steps:

[0077] (1) Ultrasonic cleaning with water, ethanol and acetone in sequence figure 1 The surface of the flat substrate shown is dried at 60°C;

[0078] (2) Add 30 mL of deionized water, 0.475 g of nickel chloride hexahydrate, 0.080 g of chromium trichloride hexahydrate, 0.28 g of hexamethylenetetramine into a 50 mL beaker, stir for 15 min, add 2 mL of ethanolamine, and continue stirring for 20 min to obtain The mixed solution, the above solution was hydrothermally reacted at 180°C for 8 hours, cooled to room temperature, washed and dried by centrifugation to obtain the Cr-NiO precursor;

[0079] (3) Then, the Cr-NiO precursor prepared in step (2) was calcined in a muffle furnace. The calcination conditions were as follows: the temperat...

Embodiment 3

[0083] Example 3, preparation of a gas sensor element with 20% Cr-NiO nanoparticles as a gas-sensitive material

[0084] Prepare a gas sensor element using 20% Cr-NiO nanoparticles as a gas-sensing material according to the following steps:

[0085] (1) Ultrasonic cleaning with water, ethanol and acetone in sequence figure 1 The surface of the flat substrate shown is dried at 60°C;

[0086] (2) Add 30 mL of deionized water, 0.475 g of nickel chloride hexahydrate, 0.107 g of chromium trichloride hexahydrate, 0.28 g of hexamethylenetetramine into a 50 mL beaker, stir for 15 min, add 2 mL of ethanolamine, and continue stirring for 20 min to obtain The mixed solution, the above solution was hydrothermally reacted at 180°C for 8 hours, cooled to room temperature, washed and dried by centrifugation to obtain the Cr-NiO precursor;

[0087] (3) The Cr-NiO precursor prepared in step (2) was calcined in a muffle furnace. The calcination conditions were: from room temperature to 500 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com