Electric drive system efficient working area simulation method, device and equipment and storage medium

A technology of electric drive system and simulation method, which is applied in design optimization/simulation, electric digital data processing, special data processing application, etc., can solve problems such as difficulty and increase large experimental time, so as to reduce research and development costs and shorten experimental time. , the result is credible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

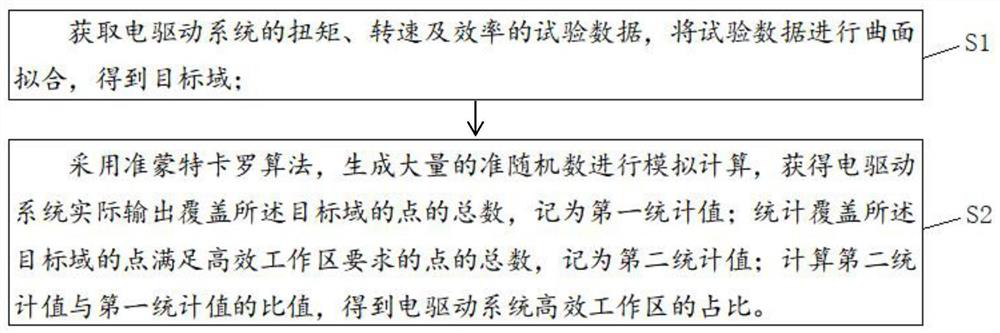

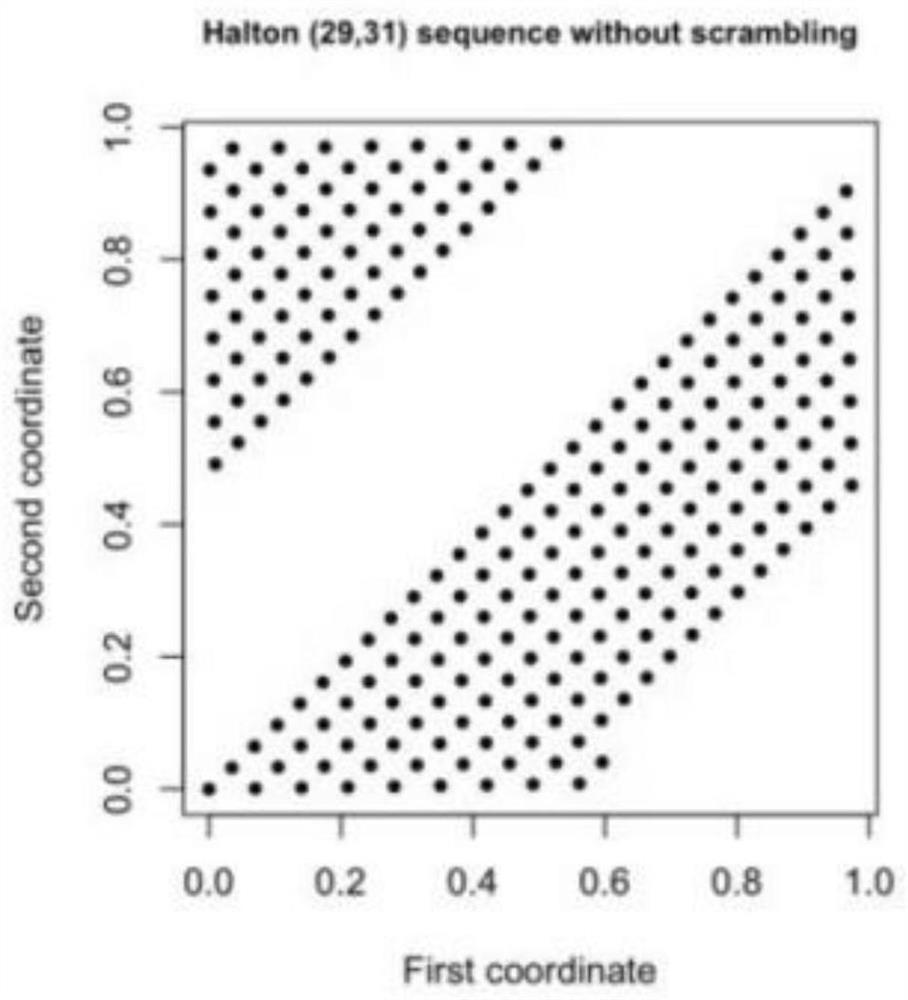

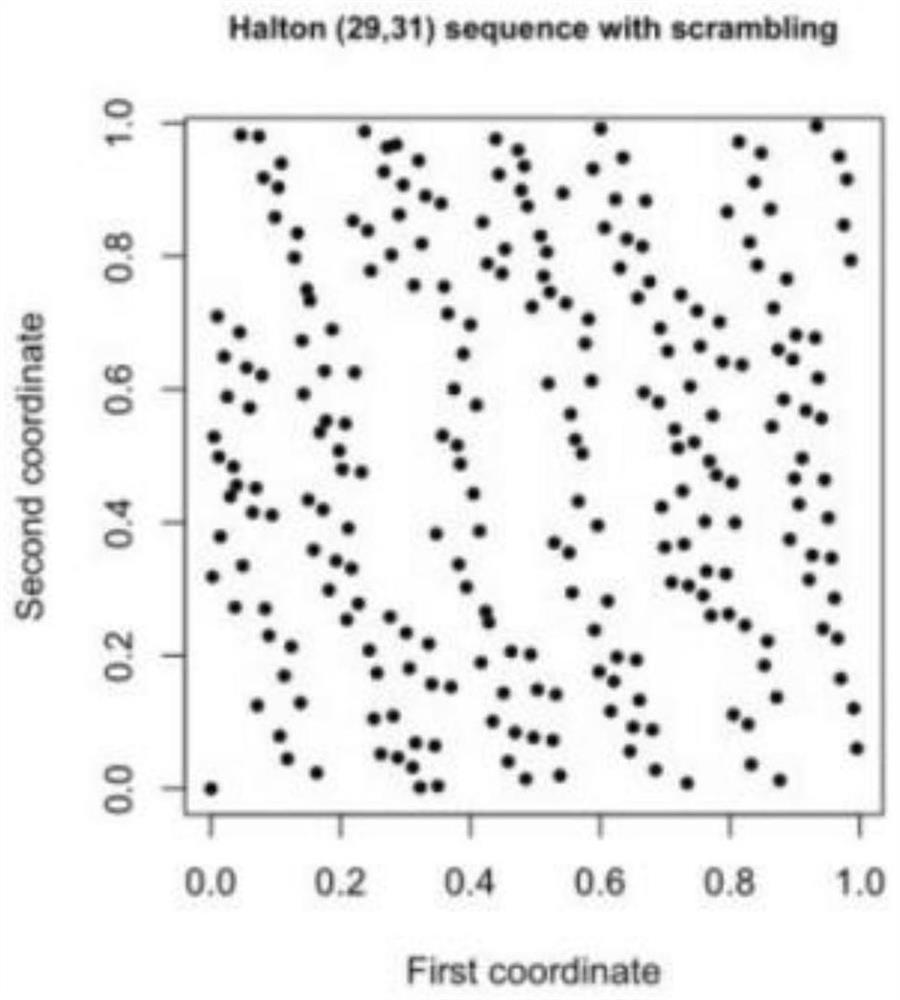

[0045]For the traditional method of counting the proportion of qualified discrete points and the total number to calculate the proportion of high-efficiency working area of the electric drive system, it is difficult to obtain close to the real value, and the interval between measurement points is intensive, and it needs to be increased. Due to the problem of a large amount of experimental time, this embodiment proposes a simulation method for the high-efficiency working area of the electric drive system. The simulation object of the simulation method is a three-dimensional surface determined by the torque, speed and efficiency of the electric drive system. Surface fitting is performed on the test data to establish a relatively accurate mathematical model, and then a large number of quasi-random numbers are generated by the quasi-Monte Carlo method for simulation calculations to obtain the total number of points in the actual output coverage area of the electric drive syste...

Embodiment 2

[0114] This embodiment provides a simulation device for an efficient working area of an electric drive system, please refer to Figure 7 , the simulation device of the high-efficiency working area of the electric drive system includes:

[0115] The surface fitting module 1 is used to obtain the test data of the torque, speed and efficiency of the electric drive system, and perform surface fitting on the test data to obtain the target domain;

[0116] The simulation module 2 generates a large number of quasi-random numbers for simulation calculation by using the quasi-Monte Carlo algorithm, and obtains the total number of points that the electric drive system actually outputs to cover the target domain, which is recorded as the first statistical value; statistics cover the target The total number of points in the domain that meet the requirements of the high-efficiency working area is recorded as the second statistical value; the ratio of the second statistical value to the...

Embodiment 3

[0124] The above-mentioned embodiment 2 describes in detail the simulation device of the high-efficiency working area of the electric drive system of the present invention from the perspective of modularized functional entities. The simulation device of the high-efficiency work area of the electric drive system of the present invention is described in detail below from the perspective of hardware processing.

[0125] Please see Figure 8 The simulation device 500 of the high-efficiency working area of the electric drive system may have relatively large differences due to different configurations or performances, and may include one or more processors (central processing units, CPU) 510 (for example, one or more processors) And memory 520, one or more storage media 530 (such as one or more mass storage devices) for storing application programs 533 or data 532 . Wherein, the memory 520 and the storage medium 530 may be temporary storage or persistent storage. The program ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com