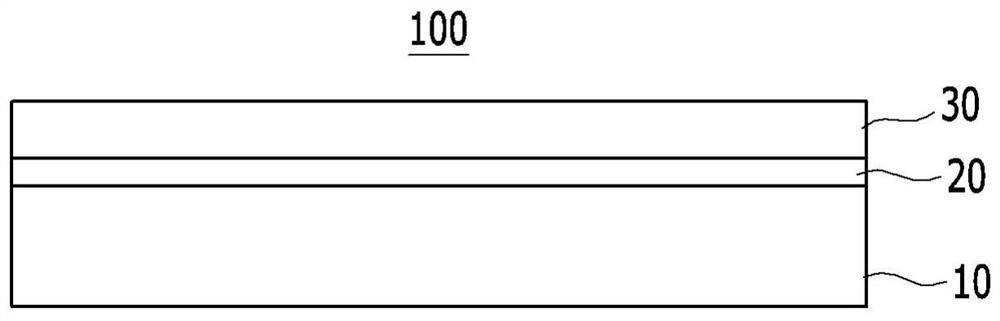

Electrical steel sheet and manufacturing method therefor

A technology of electrical steel sheet and manufacturing method, applied in the direction of manufacturing tools, circuits, electrical components, etc., can solve the problems of low bonding force, poor adhesion between the steel sheet and insulating coating, and the insulating coating cannot be uniformly formed, etc., and achieves improvement. Adhesion, Oxygen Oxidation Prevention, Effect of Improving Insulation Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0084] A slab was prepared which contained 3.4% by weight of silicon (Si) and the balance consisted of Fe and other unavoidable impurities.

[0085] The slab was heated at 1130° C. and then hot rolled to a thickness of 2.3 mm to manufacture a hot rolled sheet.

[0086] Use a shot blaster (Shot Blaster) to leave an oxide skin layer with a thickness of about 100nm on the hot-rolled sheet, and control the injection amount of fine particles to about 650g / m 3 , the injection speed is controlled to about 50km / s. Then, the hot-rolled sheet was passed between blades coated with rubber having an elasticity of about 30 MPa to control the surface roughness to about 1.5 nm. Subsequently, pickling treatment was carried out by immersing for about 50 seconds in a hydrochloric acid solution (about 15% by weight) at a temperature of about 70°C. Then, perform cleaning.

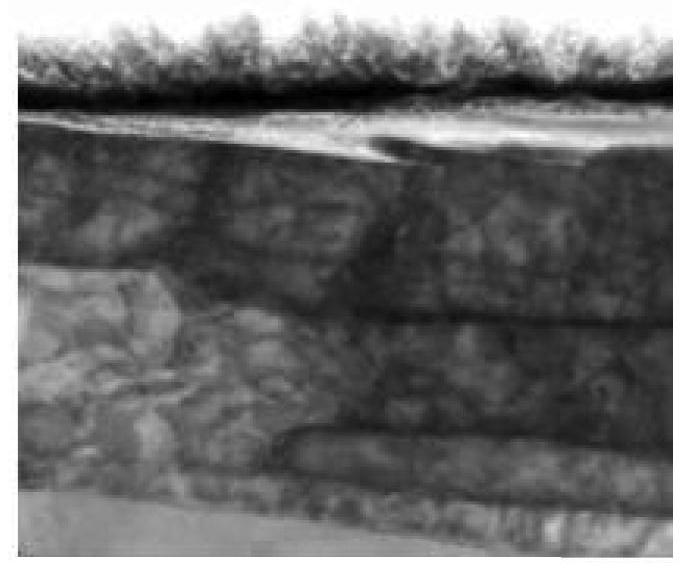

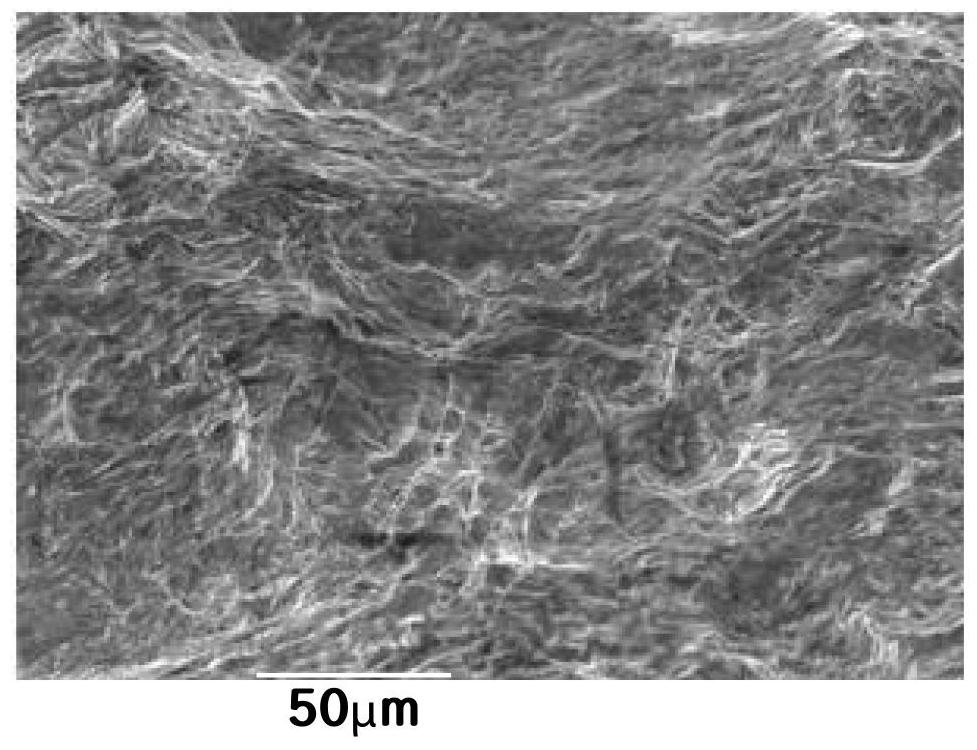

[0087] figure 2 A scanning electron microscope (SEM) picture of a cross-section of a steel plate after pickling is shown i...

experiment example 1

[0105] Experimental example 1: confirmation of rust

[0106] After the pickling and cleaning of the hot-rolled sheets in Examples and Comparative Examples, the hot-rolled sheets were coiled and placed for the time shown in Table 1 below before cold rolling.

[0107] Gloss was measured at 2 points and is shown in Table 1 below. The light intensity when the reflected light is received at the same angle as the incident light is measured using an ASTM D 523 gloss meter, and the gloss is represented by the ratio when the gloss of the glass surface with a refractive index of 1.567 is 100. At this time, the angle is set to 60°.

[0108] 【Table 1】

[0109]

[0110] As shown in Table 1, the examples in which the scale layer was present after washing had lower glossiness than the comparative examples. However, after 1 day and 2 days, the rust was prevented by the scale layer in the examples, but the rust was formed in the comparative example, and the gloss was significantly lowere...

experiment example 2

[0111] Experimental Example 2: Measuring Insulation

[0112] After finishing annealing in Examples and Comparative Examples, the insulation properties of the steel sheets were measured at three points, and are shown in Table 2 below. In addition, after forming an insulating coating layer with a thickness of 1 μm, the insulating properties were measured and shown in Table 2 below. The insulation properties were measured with a Franklin tester in accordance with the ASTM A717 international standard.

[0113] In addition, for adhesion, it is judged by whether the film layer is peeled off when the sample is bent to 180°. When observed with a microscope at x100, it is considered very good if there is no peeling, and it is considered good if there are 3 or less defects (defect) / 5cmx5cm at x100.

[0114] Iron loss (W 15 / 50 ) refers to the power loss generated when a magnetic field with a frequency of 50 Hz is magnetized by alternating current to 1.5 Tesla.

[0115] 【Table 2】

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com