An anti-scalding square bowl

A square bowl and anti-scalding technology, applied in the field of table utensils, can solve the problems of inconvenient dining table and tablecloth damage to square bowls, and achieve the effects of good thermal insulation effect, large fitting area and comfortable holding support plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

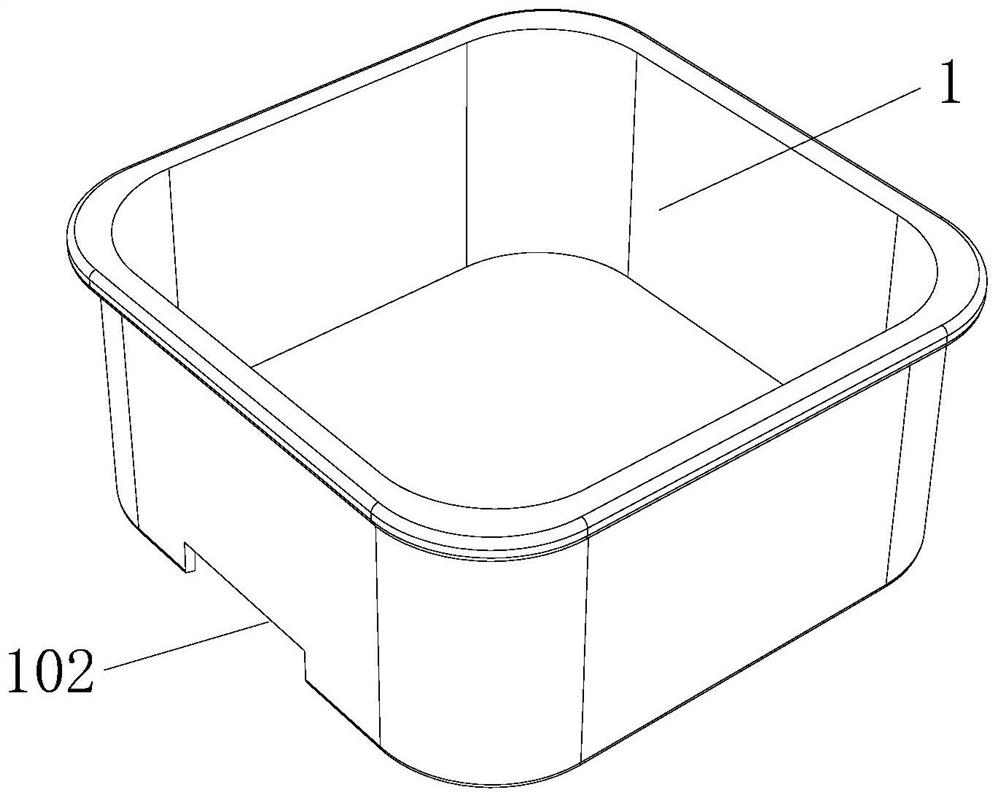

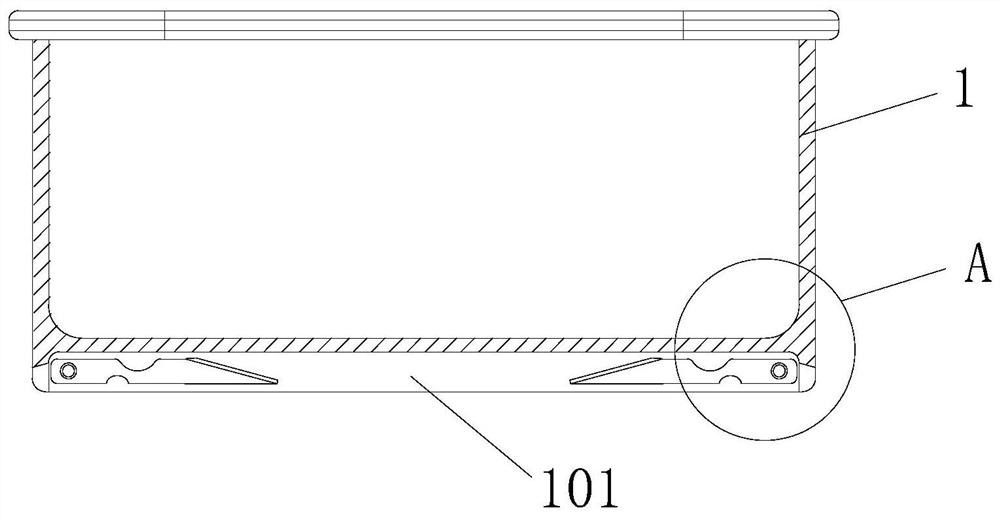

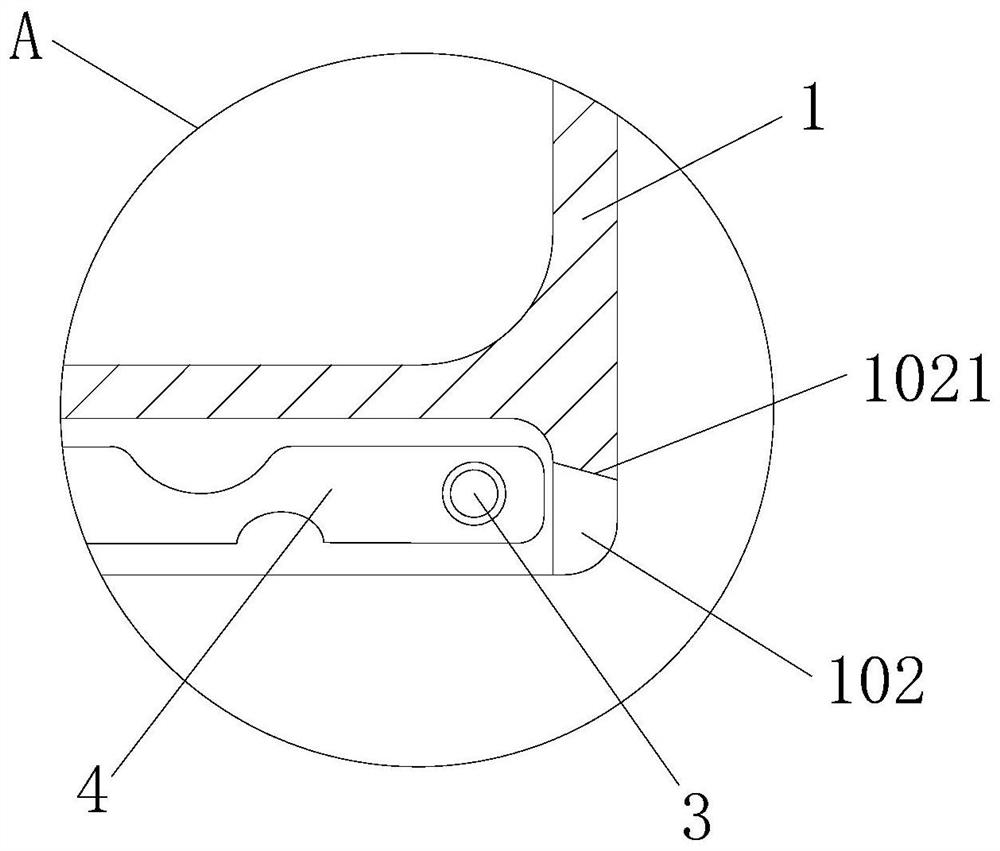

[0100] like Figure 1-7 An anti-scalding square bowl as shown includes a square bowl body 1, the bottom of the square bowl body 1 is recessed inward to form a groove 101, and the bottoms of the two opposite side walls of the square bowl body 1 are provided with notches 102, And the two gaps 102 are symmetrically arranged, the gaps 102 communicate with the groove 101, and the square bowl 1 is provided with two reinforcing ribs 2 in parallel in the groove 101, and the reinforcing ribs 2 are connected to the groove 101. The square bowl body 1 has an integrated structure, and two supporting plates 4 are rotatably installed between the two reinforcing ribs 2. The two supporting plates 4 are symmetrically arranged, and the supporting plates 4 pass through the gap when turned outward. 102, one end of the support plate 4 away from the notch 102 is designed to be inclined.

[0101] In specific use, the bottom of the square bowl body 1 can be strengthened by the reinforcing ribs 2 to p...

Embodiment 2

[0119] Basically the same as Example 1, the only difference is:

[0120] The ceramic material is a porous heat-insulating ceramic; the porous heat-insulating ceramic is composed of the following raw materials by weight: 47 parts by weight of albite, 40 parts by weight of calcite, 48 parts by weight of kaolin, 15 parts by weight of silicon dioxide, 26 parts by weight of Parts by weight of heat-resistant agent, 5 parts by weight of adhesive, 3 parts by weight of foaming agent, 1 part by weight of foam stabilizer, 1 part by weight of water reducing agent, and 13 parts by weight of pore-forming agent.

[0121] The heat-resistant agent is a mixture of zinc borate and aluminum silicate in a mass ratio of 3:2.

[0122] The binder is a mixture of sodium silicate and zinc oxide in a mass ratio of 5:7.

[0123] The blowing agent is ethoxylated nonylphenol.

[0124] The foam stabilizer is a mixture of bis(N-methylbenzamide)ethoxymethylsilane and hexaethylcyclotrisiloxane in a mass rati...

Embodiment 3

[0140] It is basically the same as Example 2, except that the accelerator is diisopropanolamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com