Tunnel inspection robot for acid gas pipeline of natural gas field

A technology for inspecting robots and pipeline tunnels, applied in manipulators, manufacturing tools, etc., can solve problems such as no ventilation facilities in tunnels, reduce escape rates, and strengthen employee labor, so as to reduce the risk of personal injury and improve detection accuracy. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

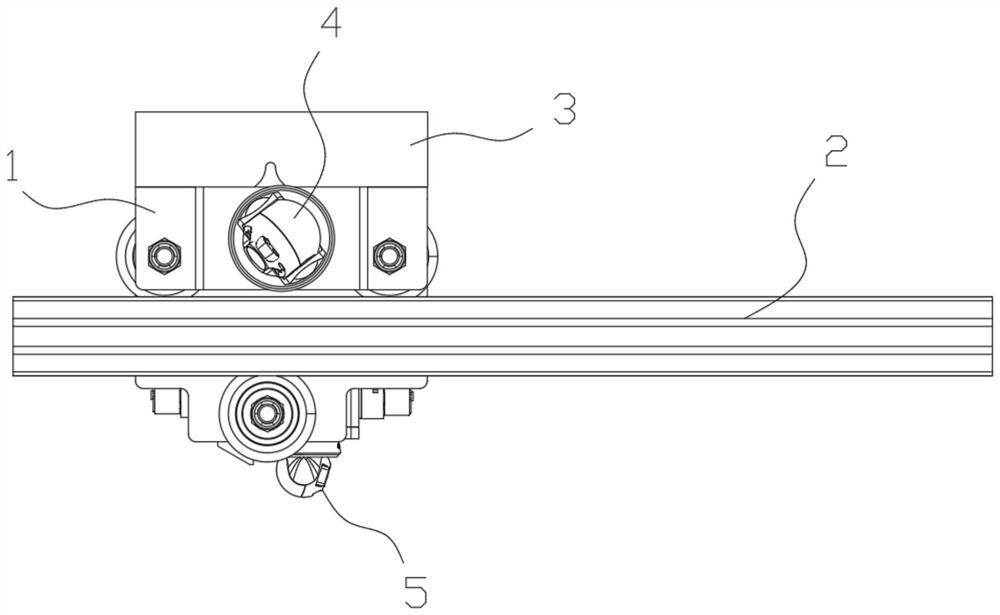

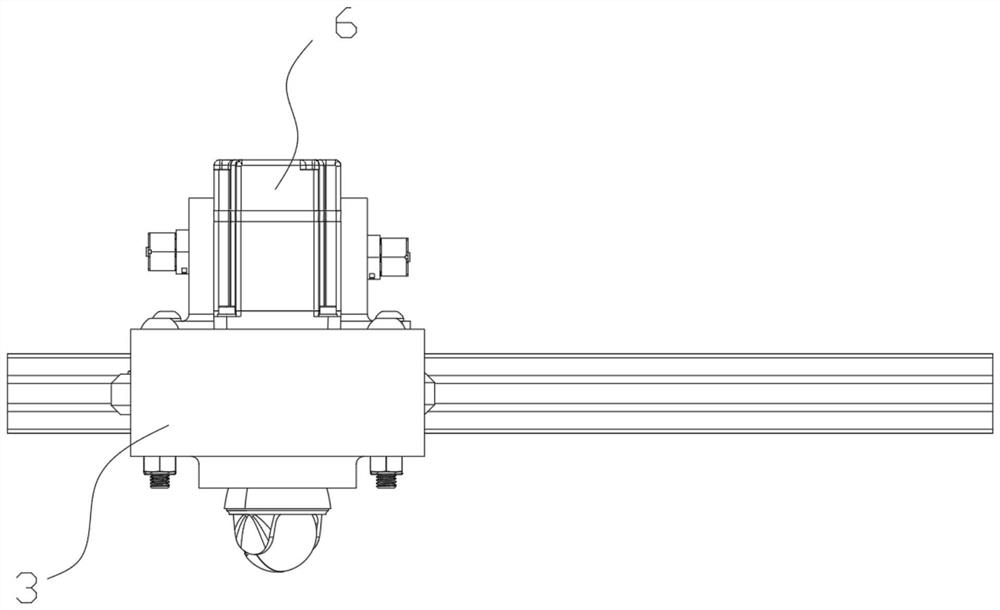

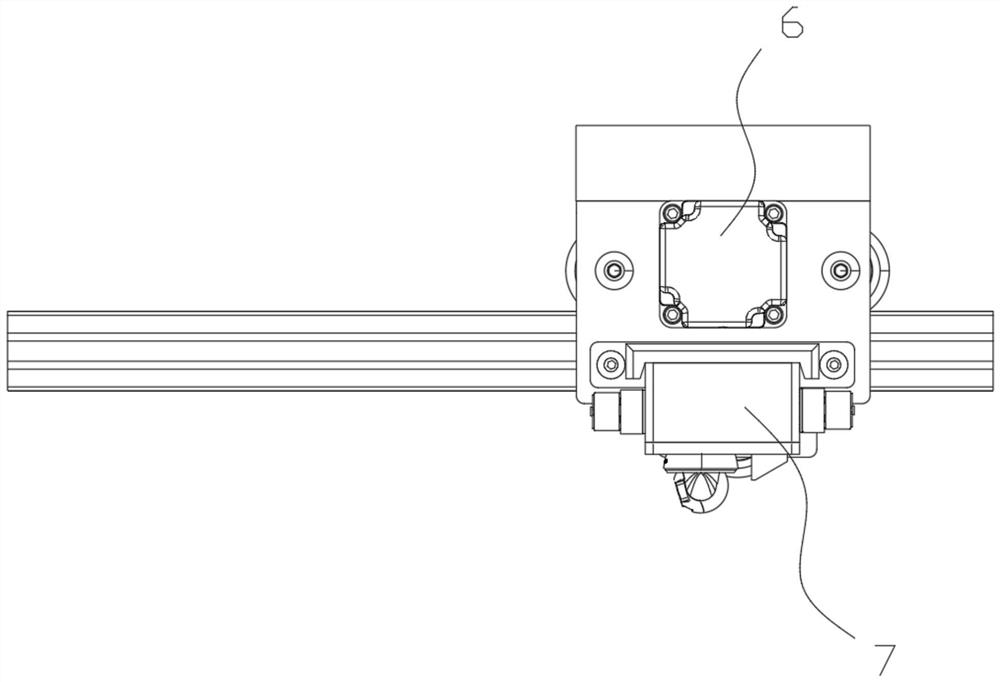

[0044] This embodiment discloses a sour gas pipeline tunnel inspection robot in a natural gas field. The inspection robot travels along the track 2 arranged along the sour gas pipeline and inspects the sour gas pipeline along the way. Among them, the sour gas pipeline is a gas transmission pipeline of a natural gas field. The pipeline is 105.59km long (excluding double lines), including 5 valve chambers, 11 spans, and 7 tunnels ranging from 247 meters to 1036 meters. 4754.49 meters.

[0045] The entire pipeline is long, and manual inspection and machine inspection can be arranged according to the actual installation position of the pipeline, especially in places and tunnels that are difficult to reach manually, an independent track 2 will be set up along the pipeline, and the distance between within limits. Since the battery life of each inspection robot is certain, a charging device will be installed at a suitable location. Each inspection robot has a wireless charging func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com