Antibacterial mildew-proof sanitary packaging bag and preparation process thereof

An antibacterial, mildew-proof and packaging bag technology, applied in the field of packaging bags, can solve the problems of unsustainable antibacterial effect, complicated process and high production cost of packaging bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] As a preferred embodiment, the antibacterial agent includes the following components in parts by weight:

[0052] 10-40 parts of n-butylisothiazolinone

[0053] Dipropylene glycol 40-60 parts

[0054] Stabilizer 1.0-5.0 parts.

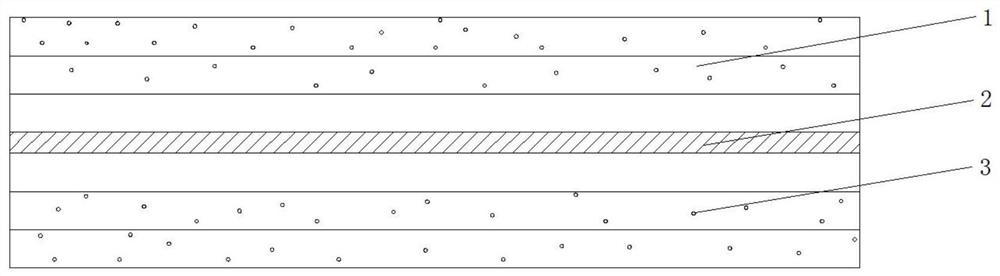

[0055] As a preferred embodiment, the surface of the film body 1 is sequentially printed with colored ink 2, varnish or matte ink 2, at least one of the colored ink 2 and the varnish or matte ink 2 contains The antibacterial agent.

[0056] As a preferred embodiment, the film body 1 contains antibacterial and antifungal resin particles 3 .

[0057] As a preferred embodiment, the film body 1 includes three layers of inner, middle and outer layers, and the outermost layer and / or inner layer of the film body 1 contains antibacterial and antifungal resin particles 3 .

[0058] As a preferred embodiment, the antibacterial and antifungal resin particles 3 are located in the outermost and middle layers of the film body 1 , or the antibacterial and ...

Embodiment 1

[0081] The preparation technology of packing bag in the present embodiment, comprises the steps:

[0082] Step 1: blown film, using three-layer co-extrusion, the antibacterial and mildew-proof film made of 60 parts by weight of submicron glass, 15 parts by weight of silver ion salt, 13 parts by weight of zinc ion salt and 10 parts by weight of copper ion salt Resin particles are added to the film body, and the added amount accounts for 3.0-5.0% of the total added amount of the film body, and when the film is blown, the screw extruder is set with 5 heating zones from front to back, and the temperatures are 167°C, 136°C, 152°C ℃, 128℃, 155℃, the temperature of the die head is 145-150°, and the rotation speed is 132-145 rpm.

[0083] Step 2: Printing, printing colored ink and varnish ink on the surface of the film in sequence, and the ink contains 3.0-5.0% of antibacterial agent accounting for the total weight of the ink.

[0084] Step 3: Composite, take the two printed films an...

Embodiment 2

[0088] The preparation technology of packing bag in the present embodiment, comprises the steps:

[0089] Step 1: blown film, using three-layer co-extrusion, the antibacterial and mildew-proof film made of 50 parts by weight of submicron glass, 10 parts by weight of silver ion salt, 10 parts by weight of zinc ion salt and 5 parts by weight of copper ion salt Resin particles are added to the film body, and the added amount accounts for 3.0-5.0% of the total added amount of the film body, and when the film is blown, the screw extruder is set with 5 heating zones from front to back, and the temperatures are 167°C, 136°C, 152°C ℃, 128℃, 155℃, the temperature of the die head is 145-150°, and the rotation speed is 132-145 rpm.

[0090] Step 2: Printing, printing colored ink and matte ink on the surface of the film in sequence, and the ink contains 3.0-5.0% of antibacterial agent accounting for the total weight of the ink.

[0091] Step 3: Composite, take the two printed films and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com