Preparation method of high-activity nanocrystalline NiO film

A nanocrystalline, high-activity technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of NiO electrochromic performance attenuation, and achieve the improvement of NiO electrochromic performance, electrochromic Good color-causing performance, the effect of avoiding particle agglomeration and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

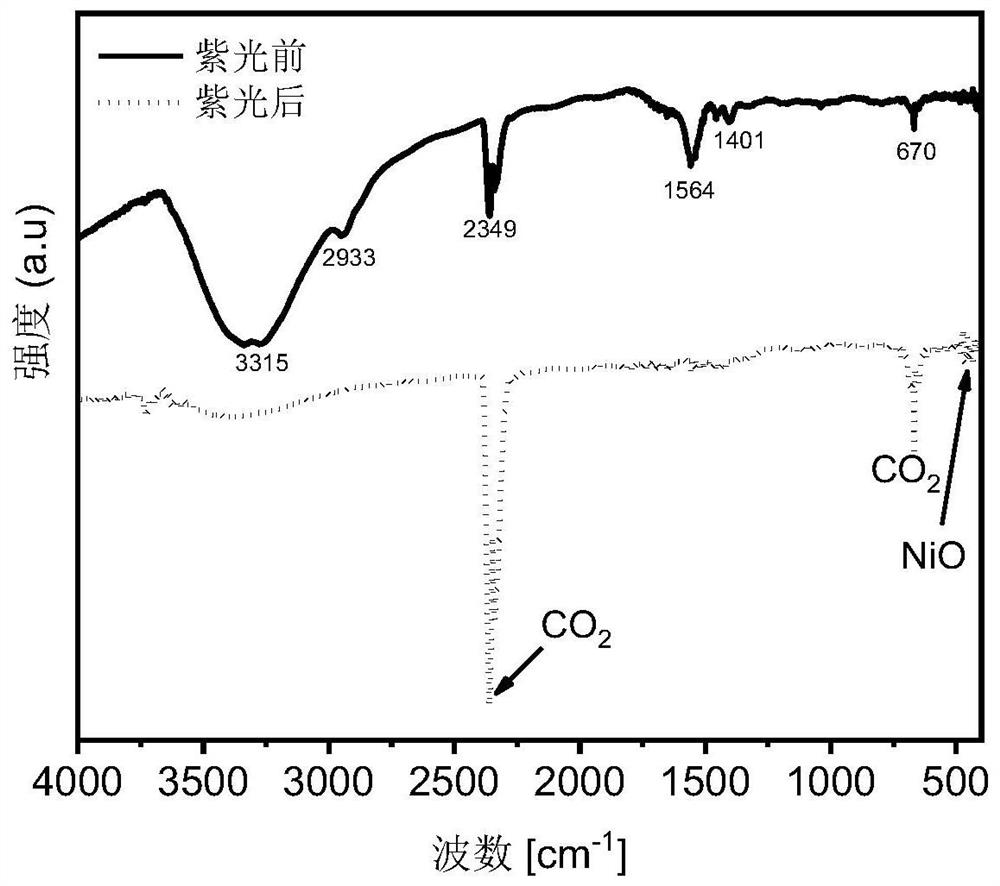

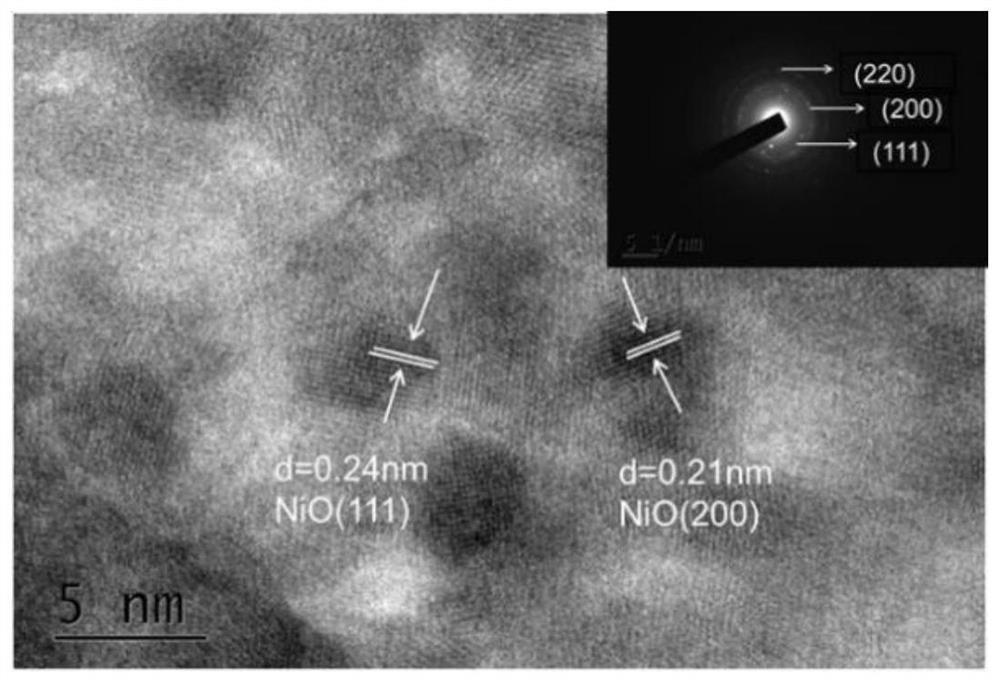

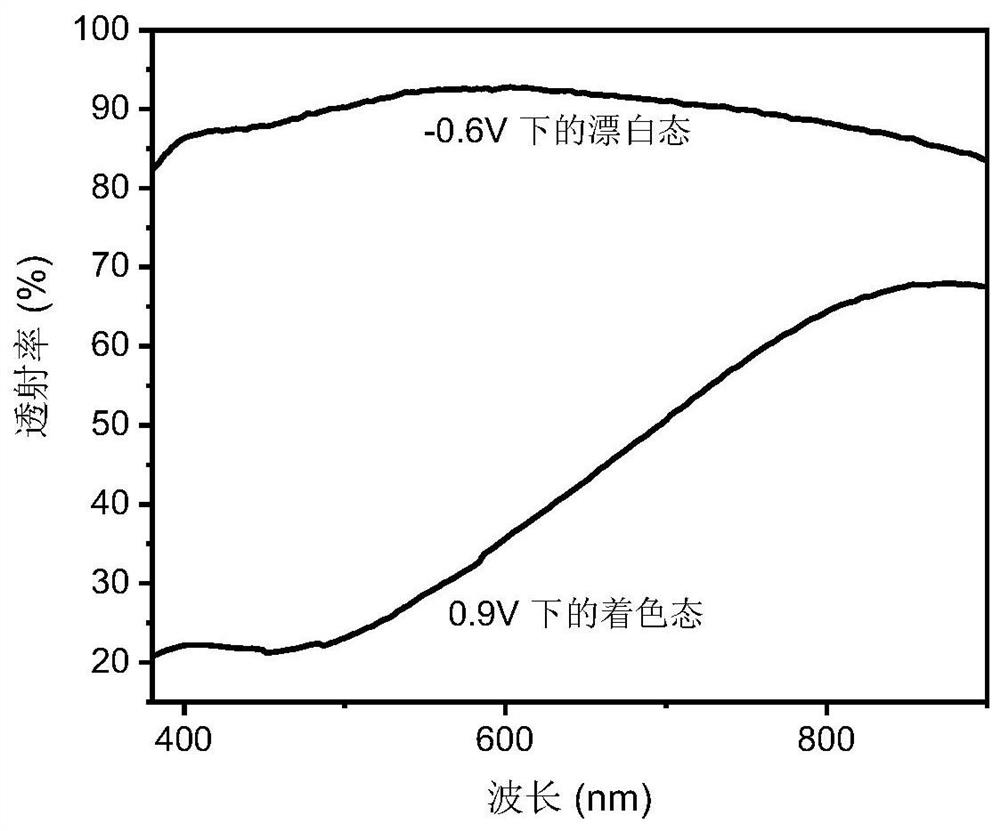

[0020] As shown in Figure 1, the preparation method of a 20-layer NiO film with an electrochromic effect of 67% at a wavelength of 500nm, the specific operations are as follows:

[0021] (1) Clean the conductive glass with common detergent, rinse with deionized water, and then use acetone, ethanol, and deionized water to sonicate for 20 minutes to obtain a conductive glass substrate with a clean surface.

[0022] (2) The PEI aqueous solution that monomer concentration is 0.2M and the nickel nitrate aqueous solution of 0.1M are mixed in equal volumes, and the PEI-Ni complex aqueous solution of 0.1M is obtained, wherein PEI monomer concentration: the concentration of nickel nitrate is 2:1.

[0023] (3) Soak the cleaned conductive glass in the PAA aqueous solution with a monomer concentration of 0.1M for 5 minutes, clean it with deionized water to obtain a negatively charged film on the surface, and then soak it in a 0.1M PEI-Ni complex. After rinsing with deionized water for 5 ...

Embodiment 2

[0027] Such as figure 2 As shown, the preparation method of a 10-layer NiO thin film with electrochromic efficiency reaching 50% at a wavelength of 500nm, the specific operations are as follows:

[0028] (1) Clean the conductive glass with common detergent, rinse with deionized water, and then use acetone, ethanol, and deionized water to sonicate for 20 minutes to obtain a conductive glass substrate with a clean surface.

[0029] (2) The PEI aqueous solution that monomer concentration is 0.2M and the nickel nitrate aqueous solution of 0.1M are mixed in equal volumes, and the PEI-Ni complex aqueous solution of 0.1M is obtained, wherein PEI monomer concentration: the concentration of nickel nitrate is 2:1.

[0030] (3) Soak the cleaned conductive glass in the PAA aqueous solution with a monomer concentration of 0.1M for 5 minutes, clean it with deionized water to obtain a negatively charged film on the surface, and then soak it in a 0.1M PEI-Ni complex. After rinsing with dei...

Embodiment 3

[0034] A method for preparing a NiO thin film with an electrochromic effect of 10% at a wavelength of 500nm, the specific operations are as follows:

[0035] (1) Clean the conductive glass with common detergent, rinse with deionized water, and then use acetone, ethanol, and deionized water to sonicate for 20 minutes to obtain a conductive glass substrate with a clean surface.

[0036] (2) The PEI aqueous solution that monomer concentration is 0.02M and the nickel nitrate aqueous solution of 0.01M are mixed in equal volumes, and the PEI-Ni complex aqueous solution of 0.01M is obtained, wherein PEI monomer concentration: the concentration of nickel nitrate is 2:1.

[0037] (3) Soak the cleaned conductive glass in the PAA aqueous solution with a monomer concentration of 0.01M for 5 minutes, then wash it with deionized water to obtain a negatively charged film on the surface, and then soak it in 0.01M PEI-Ni network 5 minutes in the aqueous solution of NiO, and after cleaning wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com