Anti-static shielding material and preparation method thereof

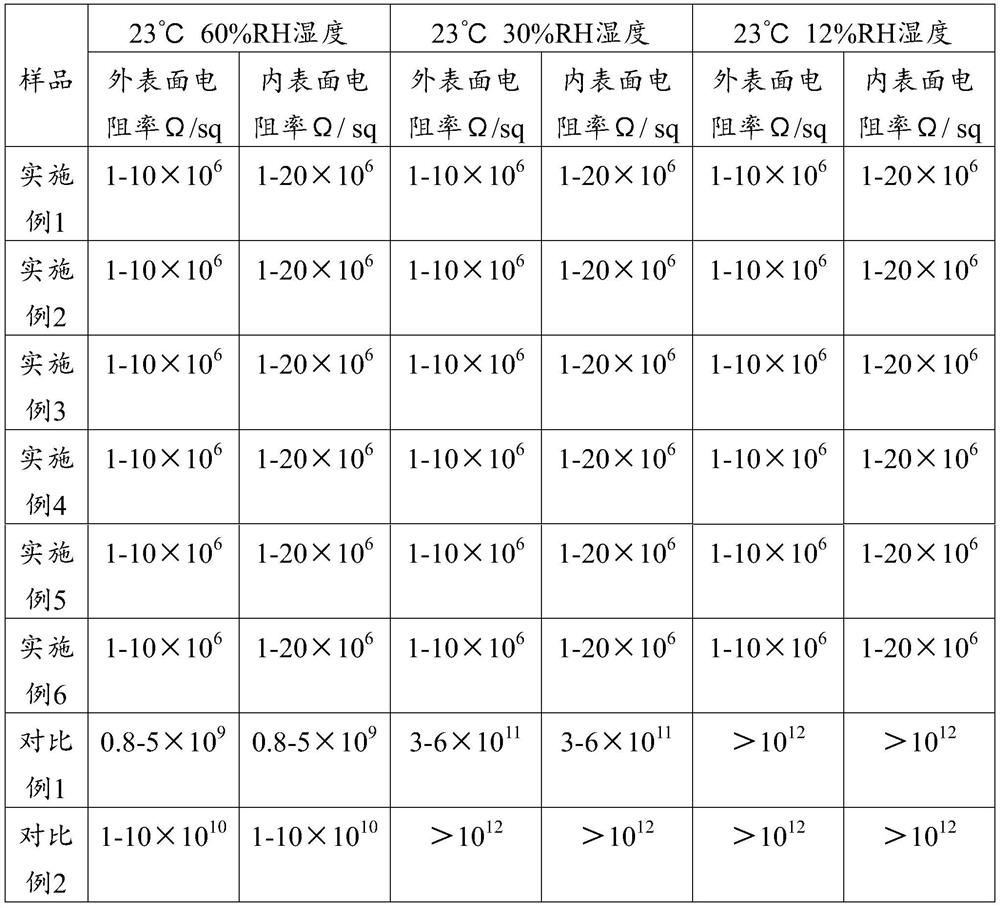

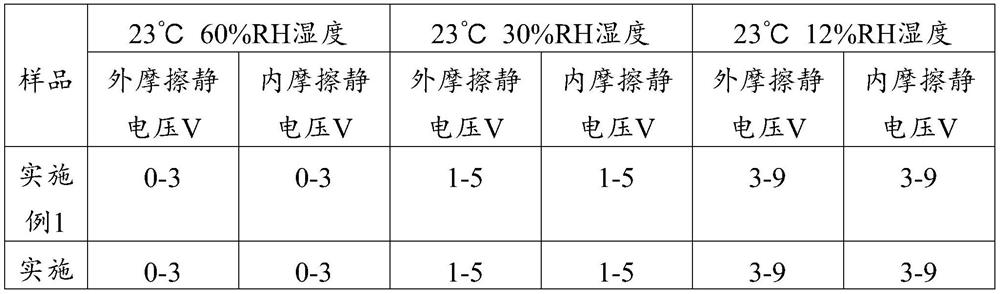

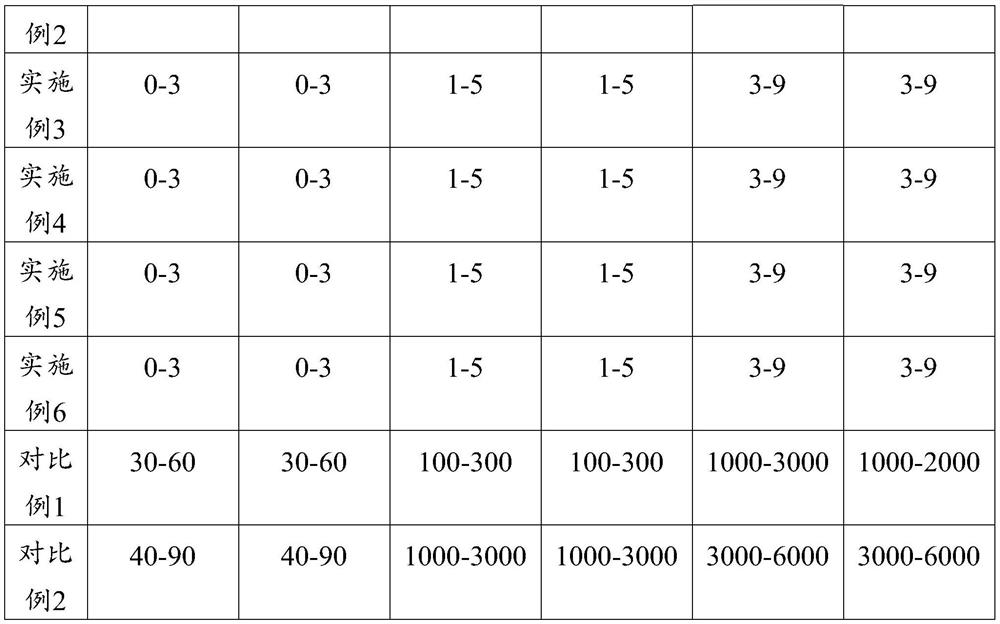

A shielding material and anti-static technology, which is applied in the field of anti-static shielding materials and its preparation, can solve the problems of high surface resistance, poor anti-static performance, and high risk of anti-static shielding bags, and achieve reduced surface resistivity and ESD risks, The effect of blocking physical loss and blocking pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also proposes a method for preparing an antistatic shielding material, which is used to prepare an antistatic shielding material, comprising the following steps:

[0039] Masterbatch processing: the antistatic layer, shielding layer and heat-sealing layer are mixed and granulated according to the required preparation materials to obtain the antistatic layer masterbatch, shielding layer masterbatch and heat-sealing layer masterbatch respectively;

[0040] Extrusion: The obtained antistatic layer masterbatch, shielding layer masterbatch and heat-sealing layer masterbatch are co-extruded and blown to form an antistatic shielding material; the processing temperature of the antistatic layer masterbatch is 170°C to 220°C, The processing temperature of shielding layer masterbatch is 180°C to 230°C, the processing temperature of heat sealing layer masterbatch is 170°C to 210°C, and the extrusion ratio of antistatic layer, shielding layer and heat sealing la...

Embodiment 1

[0048] An antistatic shielding material, which sequentially includes an antistatic layer, a shielding layer and a heat-sealing layer, wherein, in parts by weight, the antistatic layer includes the following components: 47.4 parts of high-density polyethylene, 20 parts of low-density polyethylene, linear 20 parts of low density polyethylene, 8.8 parts of superconducting carbon black, 2 parts of oxidized polyethylene wax, 1 part of antioxidant, 0.5 part of PPA powder, 0.3 part of titanate coupling agent;

[0049] The shielding layer includes the following components: 10 parts of high-density polyethylene, 20 parts of low-density polyethylene, 36 parts of linear low-density polyethylene, 25 parts of superconducting carbon black, 4 parts of oxidized polyethylene wax, 1.5 parts of antioxidant, PPA 0.8 part of powder, 1 part of maleic anhydride grafted oxidized polyethylene wax, 0.5 part of titanate coupling agent, 2 parts of coupling dispersant for conductive material; in this embod...

Embodiment 2

[0055] An antistatic shielding material, which sequentially includes an antistatic layer, a shielding layer and a heat-sealing layer, wherein, in parts by weight, the antistatic layer includes the following components: 47.4 parts of high-density polyethylene, 22.3 parts of low-density polyethylene, linear 20 parts of low-density polyethylene, 8 parts of carbon nanotubes, 1 part of maleic anhydride grafted oxidized polyethylene wax, 1 part of silicone powder, 1 part of antioxidant, 0.5 part of PPA powder, and 0.3 part of silane coupling agent;

[0056] The shielding layer includes the following components: 10 parts of high-density polyethylene, 25 parts of low-density polyethylene, 40 parts of linear low-density polyethylene, 20 parts of carbon nanotubes, 2 parts of silicone powder, 1.5 parts of antioxidant, 0.8 parts of PPA powder 3 parts, 3 parts of maleic anhydride grafted oxidized polyethylene wax, 0.5 part of silane coupling agent, 2 parts of coupling dispersant for conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com