Deformable high-temperature-resistant oil-soluble particle steam profile regulator as well as preparation method and application thereof

A technology of high temperature resistance and regulator, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problem of large formation damage, achieve low formation damage, good erosion resistance, and plugging strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

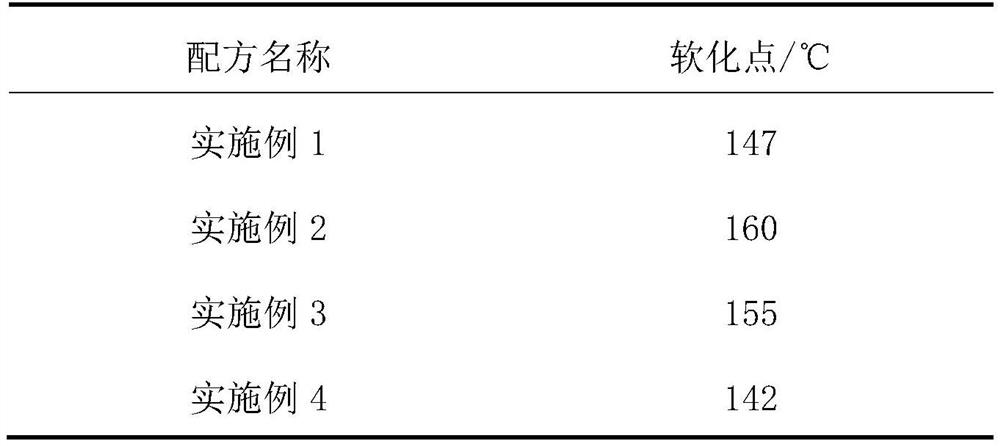

Embodiment 1

[0036] A steam profile adjuster for deformation and high temperature resistant oil-soluble particles, the composition of which is as follows by mass fraction: D-5120 petroleum resin 30%, T110 terpene resin 30%, 210# rosin resin 19%, TPV elastomer 16% , Cetyltrimethylammonium Chloride 5%.

[0037] Preparation method, the steps are as follows

[0038] Step 1: D-5120 petroleum resin, T110 terpene resin, 210# rosin resin, TPV elastomer, cetyl or octadecyltrimethylammonium chloride are subjected to air blast drying at a drying temperature of 80°C, and air blast Drying time is 5 hours;

[0039] Step 2: Take by weight the dried D-5120 petroleum resin, T110 terpene resin, 210# rosin resin, TPV elastomer, cetyl or octadecyltrimethylammonium chloride by mass ratio according to the above four formulas, Put it into the mixer, stir and heat at 170-220°C for 15 minutes, mix well and extrude through the screw, cut into sections, cut into sections, cool and granulate, and prepare the steam ...

Embodiment 2

[0041]A steam profile adjuster for deformation and high-temperature resistant oil-soluble particles. The composition is as follows in terms of mass fraction: D-5140 petroleum resin 35%, T120 terpene resin 25%, DMER-145 rosin resin 17%, TPE elastomer 18% %, Octadecyltrimethylammonium Chloride 5%.

[0042] The preparation method is the same as in Example 1.

Embodiment 3

[0044] A steam profile adjuster for deformation and high temperature resistant oil-soluble particles, the composition of which is as follows by mass fraction: D-5130 petroleum resin 30%, T100 terpene resin 30%, 145# rosin resin 15%, TPR elastomer material 21% %, Cetyltrimethylammonium Chloride 4%.

[0045] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com