Preparation method of Maotai-flavor red date liquor

A sauce-flavored, red date technology, applied in the field of liquor, can solve problems such as the large temperature difference between the inside and outside of the fermented grains, the poor air permeability of the sorghum, and the difficulty in ripening the sorghum, so as to improve the quality of liquor and the health care function, good air permeability, The effect of shortening the period of jujube grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

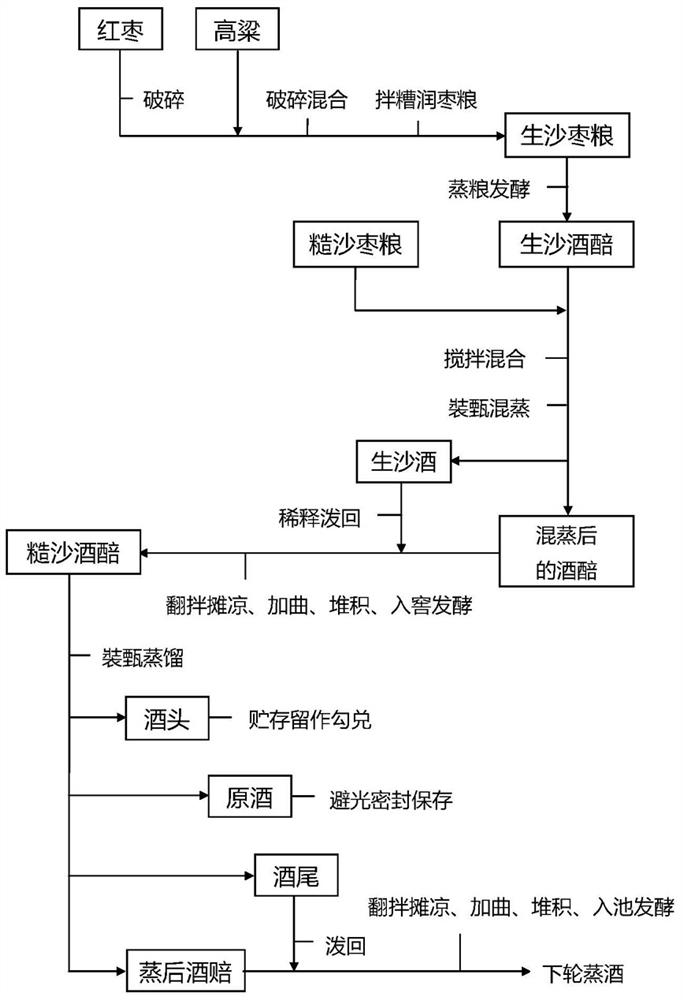

Image

Examples

Embodiment 1

[0031] Prepare Maotai-flavored jujube liquor according to the following steps:

[0032] (1) Put the red dates into the kneader after removing the core and cleaning them, stir and crush them to about 2mm, add sorghum and continue stirring and crushing until the particle size of red dates is 1-2mm, and the particle size of sorghum is 0.5-1mm; the mass ratio of red dates and sorghum is 1:4.

[0033] (2) After the red dates and sorghum are crushed to the target particle size, add grain water (that is, hot water at 85-95°C) during the stirring process. After the red dates and sorghum are evenly moistened, add the mother's grain, and stop after the raw materials and mother's grain are evenly stirred. Stir, continue to moisten the grain in the kneader for 6 hours, and obtain the raw sandy jujube grain after discharging; wherein the mass ratio of the total weight of the red date sorghum, the grain water and the mother's grain is 1:0.4:0.04.

[0034] (3) Put the raw sand jujube grains...

Embodiment 2

[0040] Prepare Maotai-flavored jujube liquor according to the following steps:

[0041] (1) Put the red dates into the kneader after removing the core and cleaning them, stir and crush them to about 2mm, add sorghum and continue stirring and crushing until the particle size of red dates is 1-2mm, and the particle size of sorghum is 0.5-1mm; the mass ratio of red dates and sorghum is 1:6.

[0042](2) After the red dates and sorghum are crushed to the target particle size, add grain water (that is, hot water at 85-95°C) during the stirring process. After the red dates and sorghum are evenly moistened, add the mother's grain, and stop after the raw materials and mother's grain are evenly stirred. Stir, continue to moisten the grain in the kneader for 7 hours, and obtain the raw sandy jujube grain after discharging; wherein the mass ratio of the total weight of the red date sorghum, the grain water and the mother's grain is 1:0.45:0.1.

[0043] (3) Put the raw sand jujube grains ...

Embodiment 3

[0049] Prepare Maotai-flavored jujube liquor according to the following steps:

[0050] (1) Put the red dates into the kneader after removing the core and cleaning them, stir and crush them to about 2mm, add sorghum and continue stirring and crushing until the particle size of red dates is 1-2mm, and the particle size of sorghum is 0.5-1mm; the mass ratio of red dates and sorghum is 1:5.

[0051] (2) After the red dates and sorghum are crushed to the target particle size, add grain water (that is, hot water at 85-95°C) during the stirring process. After the red dates and sorghum are evenly moistened, add the mother's grain, and stop after the raw materials and mother's grain are evenly stirred. Stir, continue to moisten the grain in the kneader for 8 hours, and obtain the raw sandy date grain after discharging; wherein the mass ratio of the total weight of the red date sorghum, the grain water and the mother's grain is 1:0.5:0.08.

[0052] (3) Put the raw sand jujube grains i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com