Solar panel with sieve-hole-shaped colored coating, production method of solar panel and colored solar photovoltaic module

A solar panel and color coating technology, applied in the field of solar photovoltaics, can solve the problems of complex process, high cost, and high cost of embossed templates, and achieve the effect of simple process, low cost, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Mesh-shaped golden LED coating formula (mass percentage of raw materials):

[0057]

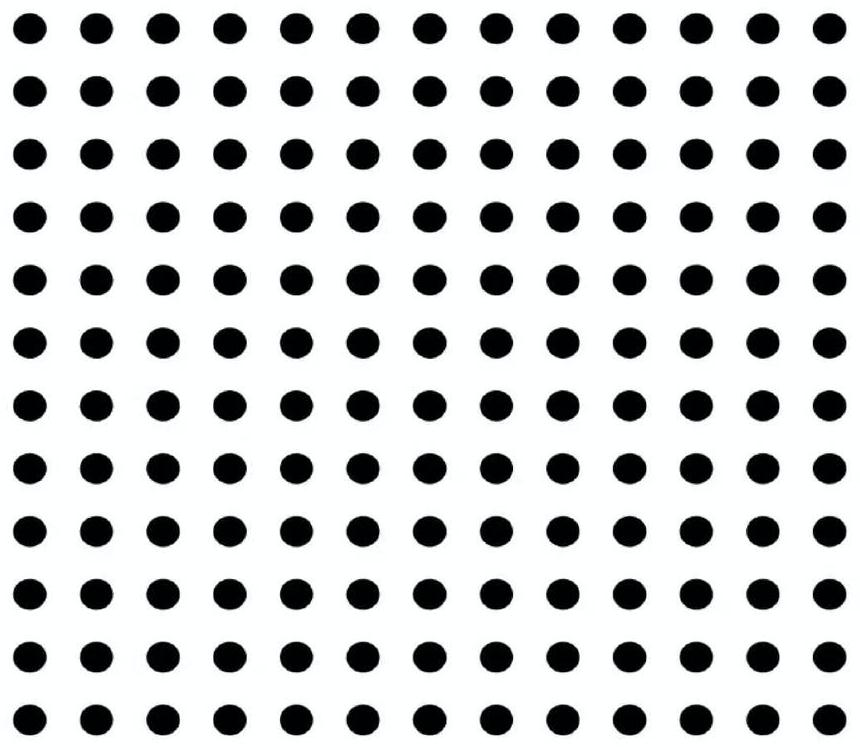

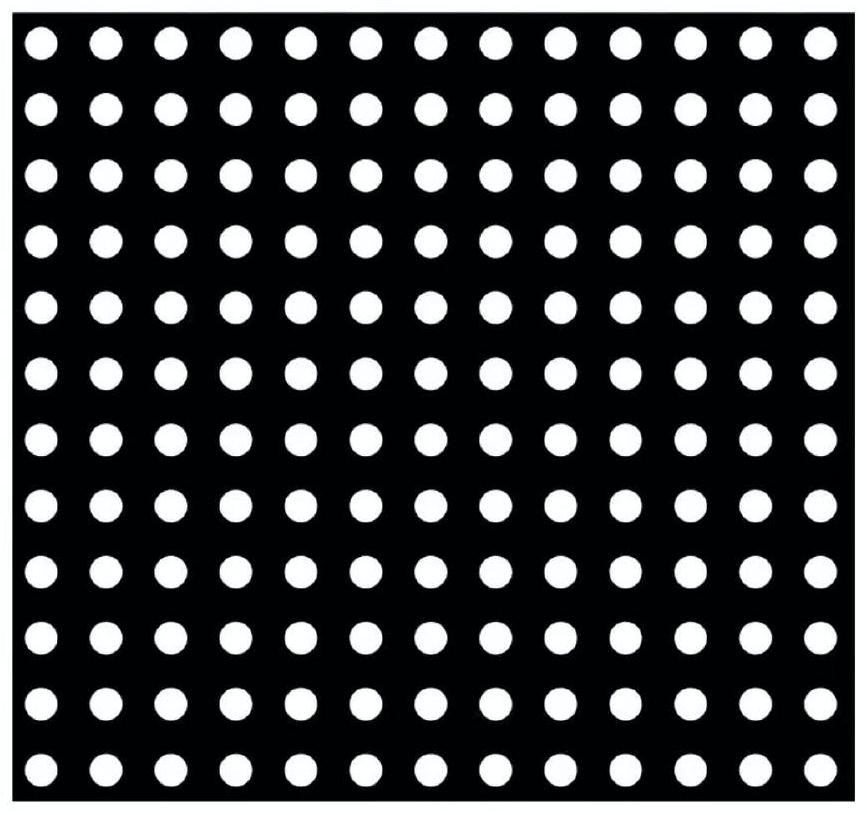

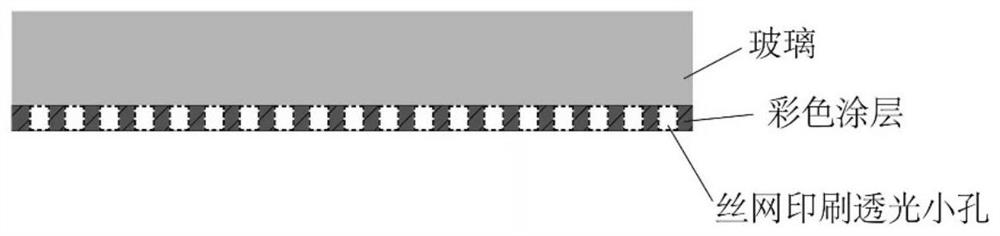

[0058] Stir the components in the above formula evenly, and print the above golden paint on the glass surface with a 200-mesh dot-shaped screen plate to obtain a color coating with a thickness of 21 microns, a light-transmitting aperture of 1 mm, and a light-transmitting area of 10%. The light-curing wavelength is 395nm, and the irradiation energy is 700mJ / cm2; the light-cured glass is heated at 160°C for 10 minutes to obtain a mesh-shaped golden solar glass panel.

[0059] When viewed from a distance, it looks like golden glass with uniform color, and when viewed closely, the surface is distributed with light-transmitting sieve holes. The physical and chemical indicators such as light transmittance are measured, see attached table 1.

Embodiment 2

[0061] Mesh-shaped silver-white LED coating formula (mass percentage of raw materials):

[0062]

[0063] Stir the components in the above formula evenly, and print the above golden paint on the glass surface with a 200-mesh dot-shaped screen plate to obtain a color coating with a thickness of 17 microns, a light-transmitting aperture of 1 mm, and a light-transmitting area of 17%. The light-curing wavelength is 395nm, and the irradiation energy is 500mJ / cm2; the light-cured glass is heated at 170°C for 8 minutes to obtain a mesh-shaped silver-white solar glass panel.

[0064] The color is uniform and silvery-white glass when viewed from a distance, and the surface is distributed with light-transmitting sieve holes when viewed from a close distance. The physical and chemical indicators such as light transmittance are measured, see Attached Table 1.

Embodiment 3

[0066] Mesh-shaped red LED coating formula (mass percentage of raw materials):

[0067]

[0068] Stir the components in the above formula evenly, and print the above colored paint on the surface of the photovoltaic glass with a 200-mesh dot-shaped screen plate to obtain a red mesh coating with a thickness of 22 microns, a light-transmitting aperture of 1 mm, and a light-transmitting area of 25%; The wavelength of LED light curing is 395nm, and the irradiation energy is 1000 mJ / cm2; the light-cured glass is heated at 180°C for 5 minutes to obtain a mesh-shaped red solar glass panel.

[0069] From a long distance, it looks like red glass with a uniform color, and from a close view, there are light-transmitting sieve holes on the surface, and the physical and chemical indicators such as light transmittance are measured, see attached table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap