Treatments of organic waste

A technology of organic waste and waste, applied in the field of organic waste treatment, can solve the problems of reducing the efficiency of bacterial fermentation process, increasing the complexity and loss of reactor design and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

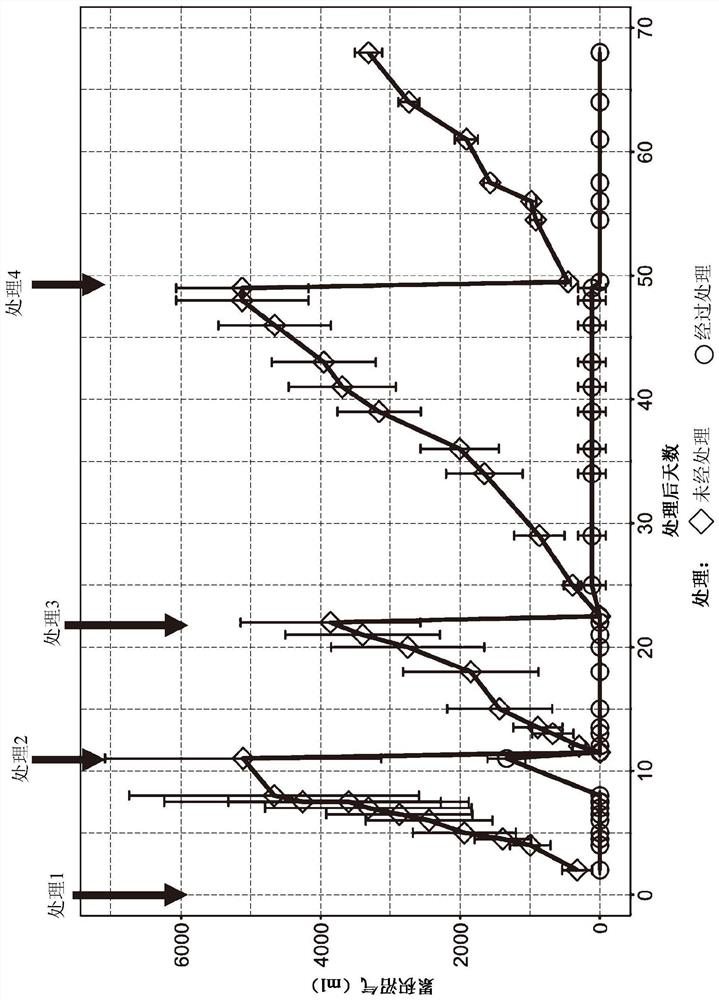

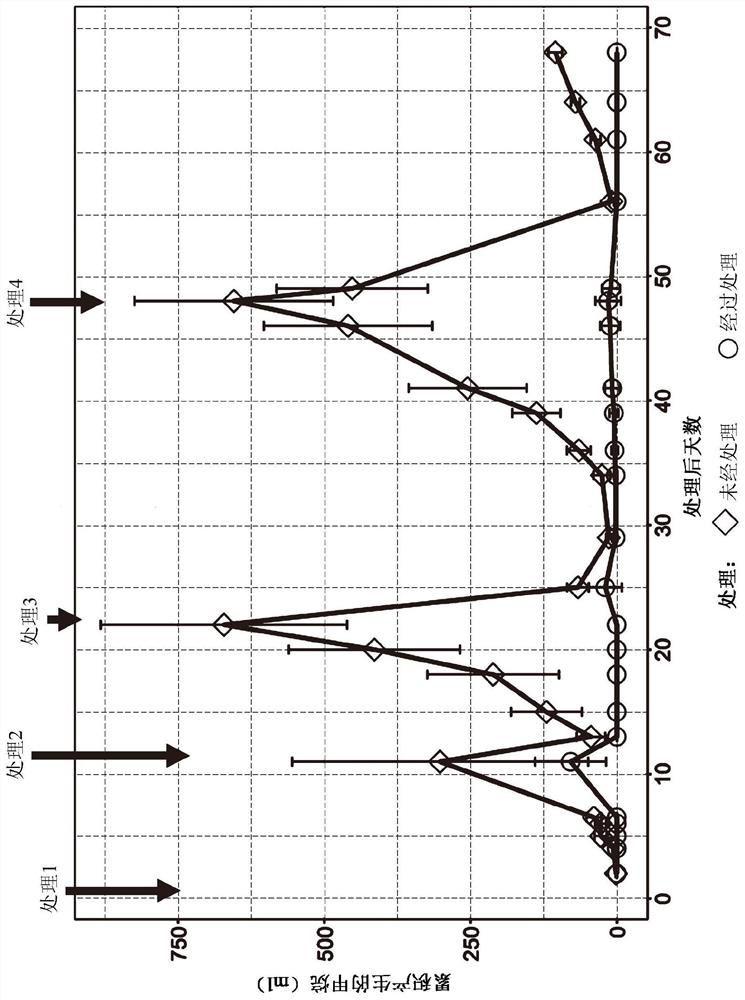

[0146] Example 1 - Evaluation of the Effect of the Treatment of the Invention on Cumulative Biogas Production

[0147] Six 25 L drums containing 16 kg of slurry were used to assess the effect of the treatment of the invention. The slurry used was from Holstein Friesian grass fed cows.

[0148] Three buckets received no positive treatment, but were treated with water only and served as controls. Three other barrels were treated according to the invention with a composition capable of generating active species.

[0149] The composition used in the treatment included urea hydrogen peroxide adduct and potassium iodide. The concentration of the composition was 2.66 g / kg slurry, based on 2.4 g hydrogen peroxide-urea adduct and 0.265 g potassium iodide. This corresponds to a 4.2:1 ratio of hydrogen peroxide to iodide ions.

[0150] All barrels were sealed with modified lids to which air bags were attached, allowing any generated biogas to be collected. As the slurry biodegrades,...

Embodiment 2

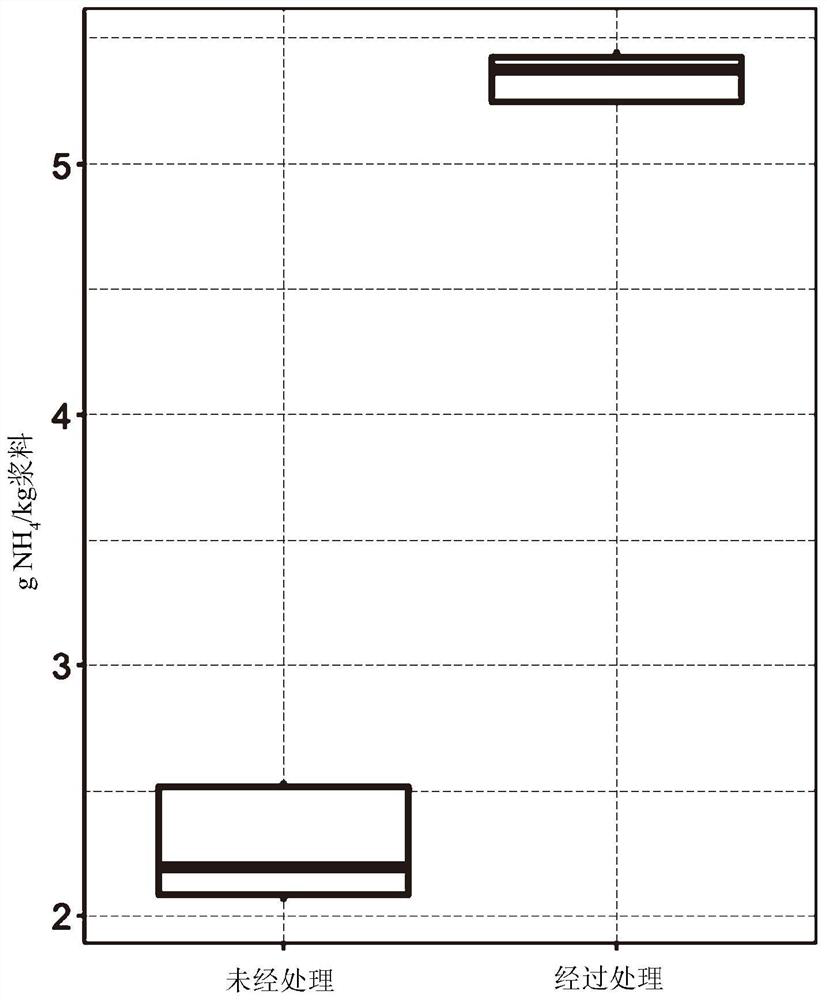

[0155] Example 2 - Evaluation of the Effect of the Treatment of the Invention on the Concentration of Ammonium Compounds

[0156] The data in this example were generated from the same batch of slurry as in Example 1. Therefore, the treatment composition, controls and treatment conditions were the same as for Example 1.

[0157] At the end of each stage of treatment, the slurry in the 25L drums was thoroughly mixed and a subsample was taken just prior to reprocessing. This was immediately mixed with 4 volumes of extractant (2M KCl) for one hour before filtration was performed.

[0158] The ammonium concentration in the filtrate was measured using the colorimetric indophenol blue method as performed in the Merck Ammonium Test. image 3 Displays the ammonium concentration results for subsamples taken at the end of the experiment, ie after the fourth stage treatment.

[0159] image 3 It was shown that organic waste treated according to the invention maintains higher levels of...

Embodiment 3

[0160] Example 3 - Assessing the Fertilizer Capacity of Organic Waste Treated According to the Invention

[0161] The data in this example were generated from the same batch of slurry as in Example 1. Therefore, the treatment composition, controls and treatment conditions were the same as for Example 1.

[0162] On day 48 (end of stage 3) 1 kg of slurry was withdrawn from each 25 L bucket in order to assess the effect of the treatment on the fertilization capacity of the treated waste with respect to plant growth.

[0163] Three treatments were tested:

[0164] 1) No modification

[0165] 2) Modified with untreated slurry

[0166] 3) Modification with treated slurry

[0167] Ten replicate pots per treatment were filled with 1 kg of topsoil (+ / - modification). The slurry is premixed into the soil using a volume equal to the guide rate of up to 33 tonnes of slurry per hectare in one slurry application. This means that the amount of slurry used is 45g of slurry per pot. (“...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com