Synthesis process of sodium p-nitrophenolate

A technology of sodium p-nitrophenolate and synthesis process, which is applied in the field of fine chemical product synthesis, can solve the problems of excessive temperature and pressure rise, low production efficiency, high labor intensity, etc., and achieves mild reaction, easy handling, and excellent resistance. alkaline effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

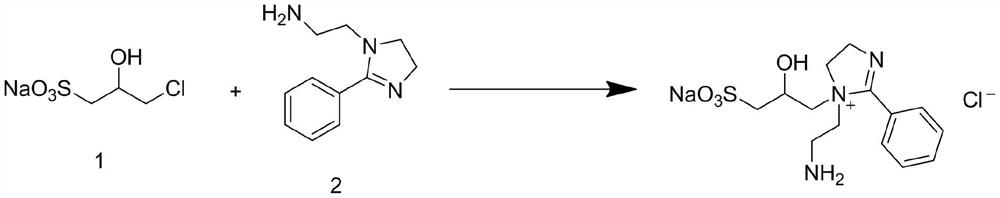

[0029] Preparation of quaternary ammonium surfactants:

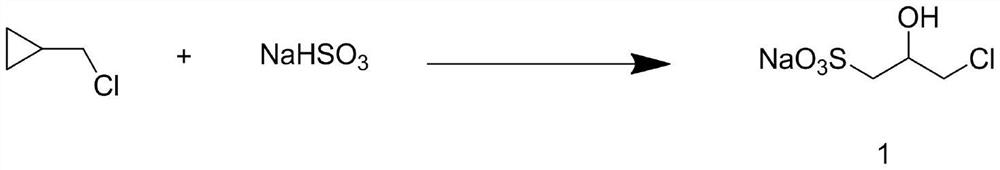

[0030] Step S11, mix sodium sulfite and deionized water to prepare a saturated solution, set the temperature at 85°C, add epichlorohydrin dropwise, and control the dropwise addition time to 1.5h, after the dropwise addition, keep the temperature unchanged, and continue the reaction for 1.5 h, after the reaction, the temperature of the reaction solution was lowered to room temperature, and crystals were precipitated, then filtered under reduced pressure, and recrystallized with deionized water to obtain intermediate 1;

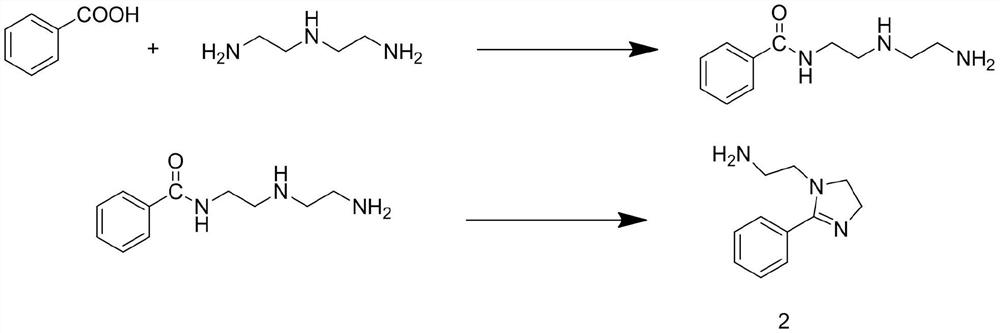

[0031] Step S12, mix xylene and diethylenetriamine, set the temperature to 90°C, add the mixed xylene and diethylenetriamine dropwise to benzoic acid, after the dropwise addition, continue to heat up to 140°C, at this The reaction was continued at low temperature for 3 hours, and then the temperature was raised to 240° C., and the reaction was continued for 3 hours. After the reaction, intermediate 2 was ...

Embodiment 2

[0035] Preparation of quaternary ammonium surfactants:

[0036] Step S11, mix sodium sulfite and deionized water to prepare a saturated solution, set the temperature at 85°C, add epichlorohydrin dropwise, and control the dropwise addition time to 1.8h. After the dropwise addition, keep the temperature unchanged and continue the reaction for 1.5 h, after the reaction, the temperature of the reaction solution was lowered to room temperature, and crystals were precipitated, then filtered under reduced pressure, and recrystallized with deionized water to obtain intermediate 1;

[0037] Step S12, mix xylene and diethylenetriamine, set the temperature to 90°C, add the mixed xylene and diethylenetriamine dropwise to benzoic acid, after the dropwise addition, continue to heat up to 145°C, at this The reaction was continued at low temperature for 3 hours, and then the temperature was raised to 240° C., and the reaction was continued for 3 hours. After the reaction, Intermediate 2 was o...

Embodiment 3

[0041] Preparation of quaternary ammonium surfactants:

[0042] Step S11, mix sodium sulfite and deionized water to prepare a saturated solution, set the temperature at 85°C, add epichlorohydrin dropwise, and control the dropwise addition time to 2h, after the dropwise addition, keep the temperature unchanged, and continue the reaction for 1.5h , after the reaction, the temperature of the reaction solution was lowered to room temperature, crystals were precipitated, then filtered under reduced pressure, and recrystallized with deionized water to obtain intermediate 1;

[0043] Step S12, mix xylene and diethylenetriamine, set the temperature to 90°C, add the mixed xylene and diethylenetriamine dropwise to benzoic acid, after the dropwise addition, continue to heat up to 150°C, at this The reaction was continued at low temperature for 3 hours, and then the temperature was raised to 240° C., and the reaction was continued for 3 hours. After the reaction, intermediate 2 was obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com