Fully-degradable high-strength rope knot temporary plug

A high-strength, fully degradable technology, applied in the direction of mining fluids, braids, fiber chemical characteristics, etc., can solve the problems of low compressive strength, poor solubility, low degradation rate, etc., and achieve the effect of shortening the fracturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

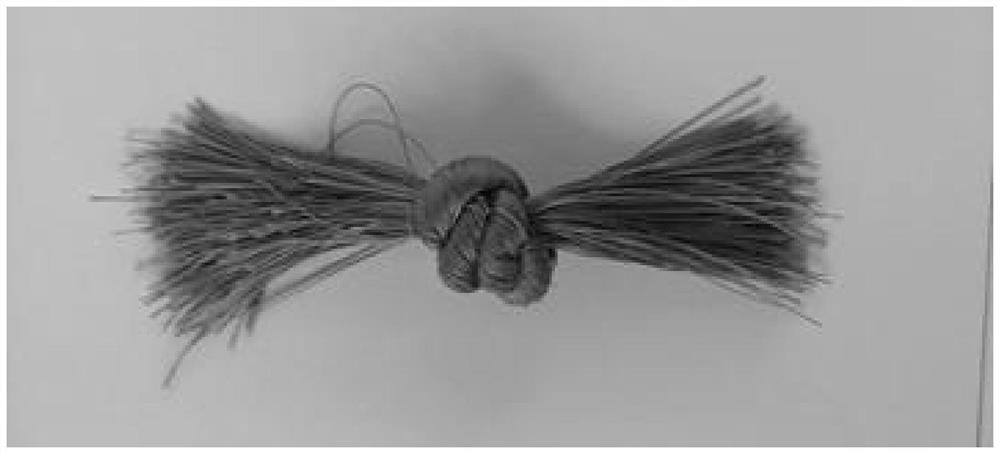

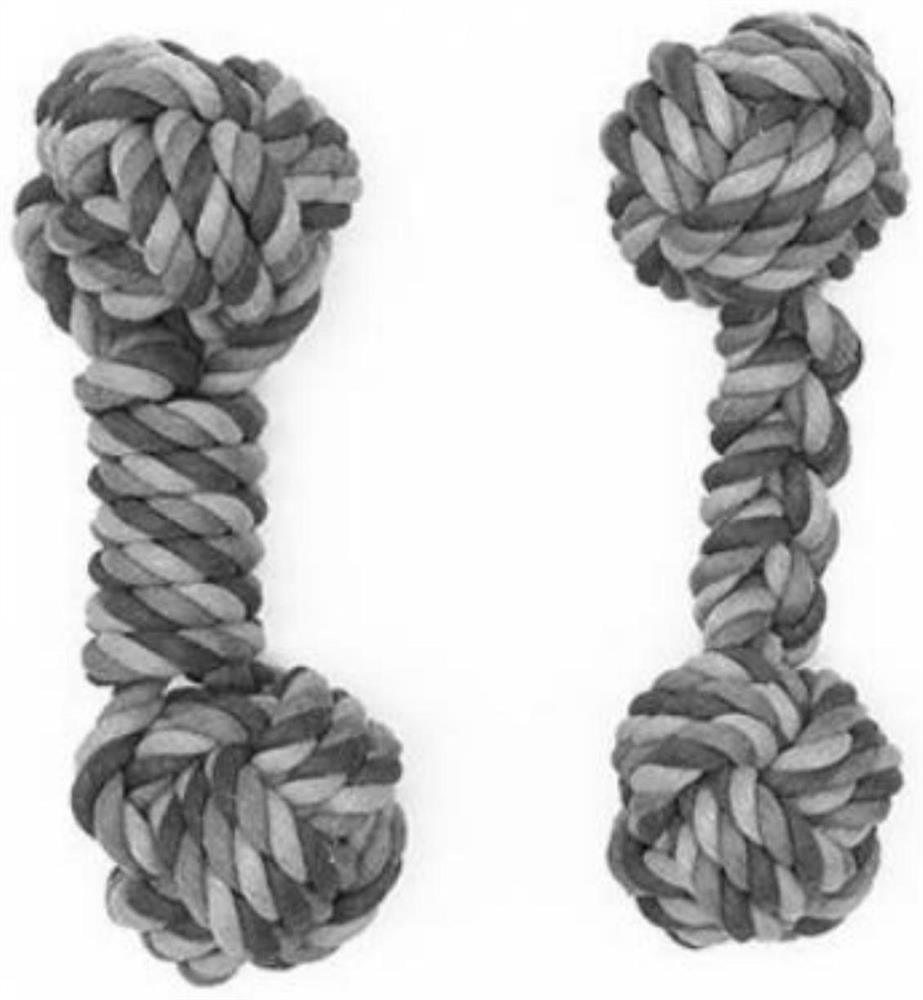

[0027] A preparation method for fully degradable high-strength knot temporary plugging:

[0028] First, prepare polymer A: add 200 grams of distilled water to a 500 milliliter reaction bottle, add 30 grams of triethylene glycol divinyl ether, 15 grams of butanediol, 7 grams of 4-hydroxybutyl vinyl ether, 2 Gram 2-acrylamide-2-methylpropanesulfonic acid (AMPS), stirring and dissolving, obtains solution A, for subsequent use; The ammonium persulfate that takes 0.2 gram is dissolved in 25 grams of distilled water, dissolves, and obtains solution B, for subsequent use; Add solution A into the reaction vessel, keep warm in a water bath at 50°C, and stir; slowly add solution B dropwise into the reaction vessel, and the time is controlled within 1 hour to complete the dropwise addition; after dropping, continue to keep warm at 50°C for 8-10 hours; Drying yields Polymer A.

[0029] Next, 2g of plasticizer epoxidized soybean oil and 2g of modified surfactant sodium dodecylsulfonate ar...

Embodiment 2

[0031] A preparation method for fully degradable high-strength knot temporary plugging:

[0032] First, prepare polymer A: add 200 grams of distilled water to a 500 milliliter reaction bottle, add 35 grams of triethylene glycol divinyl ether, 5 grams of butanediol, 10 grams of 4-hydroxybutyl vinyl ether, 3 Gram 2-acrylamide-2-methylpropanesulfonic acid (AMPS), stirring and dissolving, obtain solution A, for subsequent use; The ammonium persulfate that takes 0.3 gram is dissolved in 25 gram of distilled waters, dissolves, obtains solution B, for subsequent use; Add the prepared solution A into the reaction container, keep warm at 50°C in a water bath, and stir; slowly add solution B dropwise into the reaction container, and the time is controlled within 1 hour to complete the dropwise addition; -10h; dry to obtain polymer A.

[0033] Secondly, 2g of plasticizer epoxy soybean oil and 2g of modified surfactant sodium dodecylsulfonate are added to polymer A, placed in a mixer for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com