Composite conductive agent with special structure for lithium ion battery and preparation method of battery containing the conductive agent

A composite conductive agent and lithium-ion battery technology, applied in battery electrodes, structural parts, secondary batteries, etc., can solve problems such as high addition amount and uneven dispersion of conductive agent, achieve high conductivity, reduce material cost, and easily scattered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

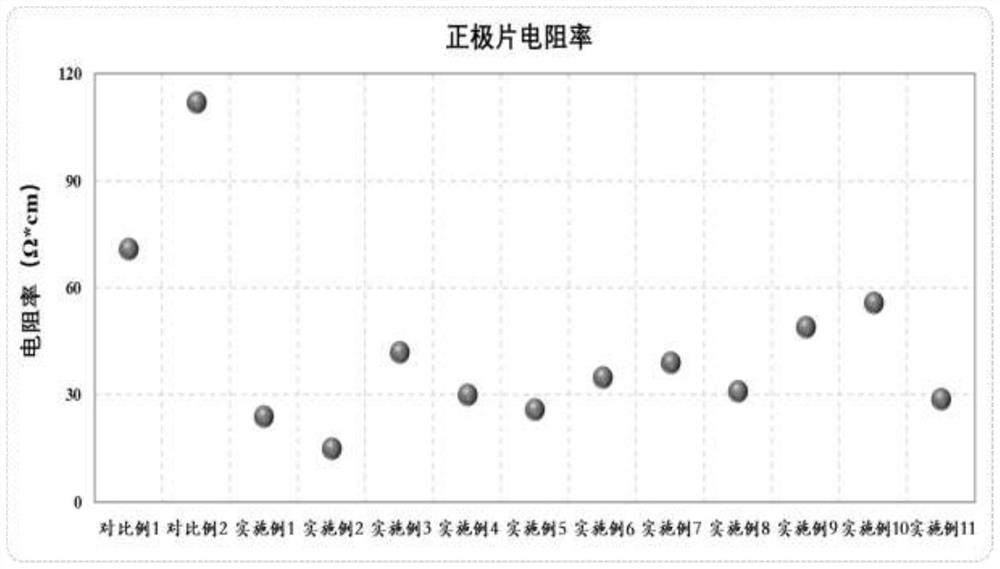

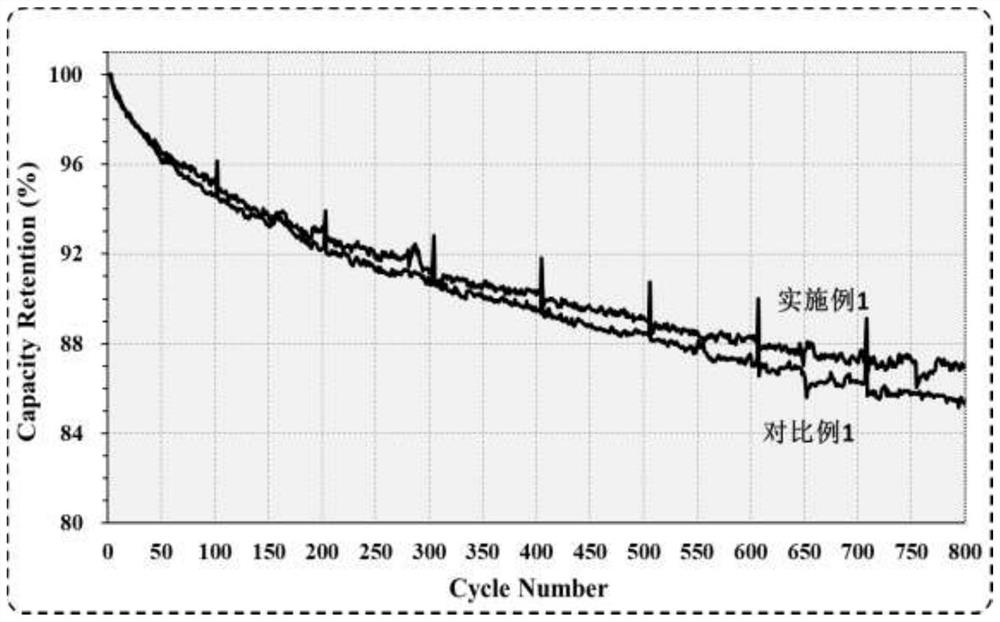

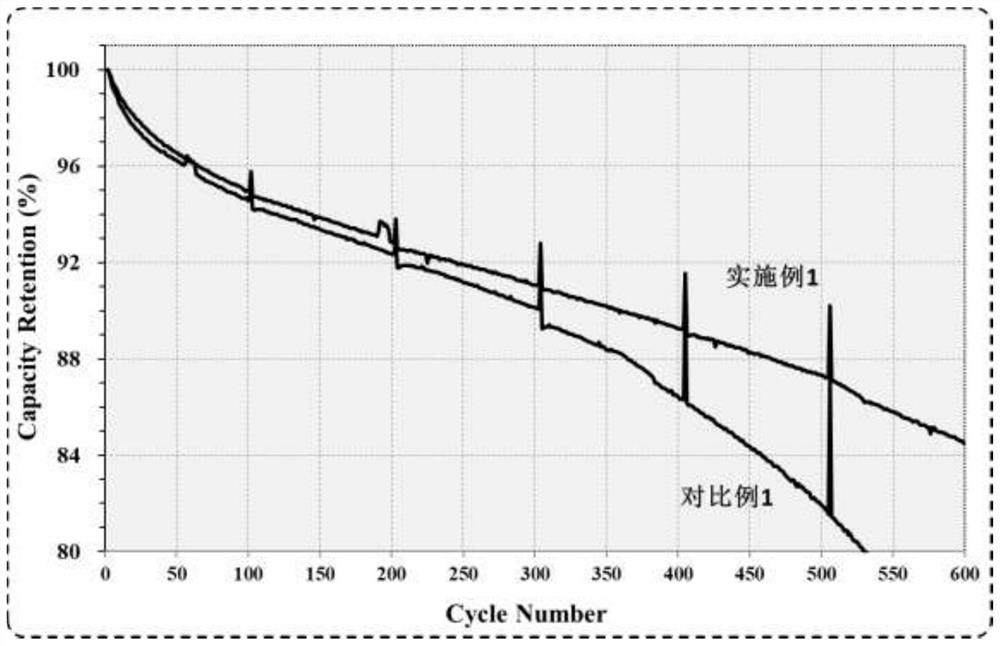

Embodiment 1

[0040]1) Disperse 4g of polyacrylonitrile and 4g of Super-P into a conical flask filled with 50ml of dimethylformamide, stir for 6h to disperse evenly;

[0041] 2) Inject the uniformly dispersed mixed solution into a plastic syringe connected with a stainless steel needle, the diameter of which is 1.0mm;

[0042] 3) Adjust the injection rate of the syringe to 0.2mL / min through the precision propeller, and place a collector made of aluminum at about 15cm in the direction of the stainless steel needle to collect the prepared product, that is, a composite conductive agent with a special structure;

[0043] 4) The obtained composite conductive agent with special structure is extracted with alcohol at 80° C. for 10 minutes to infiltrate, and then the solvent is removed; and then dried to obtain the composite conductive agent with special structure.

[0044] 5) Preparation of the positive pole piece: mix the positive active material lithium cobaltate, the special structure composite...

Embodiment 2

[0048] 1) Disperse 4g of polyacrylonitrile and 4g of Ketjen Black in a conical flask filled with 50ml of dimethylformamide, stir for 6h to disperse evenly;

[0049] 2) Inject the uniformly dispersed mixed solution into a plastic syringe connected with a stainless steel needle, the diameter of which is 1.0mm;

[0050] 3) Adjust the injection rate of the syringe to 0.2mL / min through the precision propeller, and place a collector made of aluminum at about 15cm in the direction of the stainless steel needle to collect the prepared product, that is, a composite conductive agent with a special structure;

[0051] 4) The obtained composite conductive agent with special structure is extracted with alcohol at 80° C. for 10 minutes to infiltrate, and then the solvent is removed; and then dried to obtain the composite conductive agent with special structure.

[0052] 5) Preparation of the positive pole piece: mix the positive active material lithium cobaltate, the special structure compo...

Embodiment 3

[0056] 1) Disperse 4g of polyacrylonitrile and 4g of acetylene black into an Erlenmeyer flask filled with 50ml of dimethylformamide, stir for 6h to disperse evenly;

[0057] 2) Inject the uniformly dispersed mixed solution into a plastic syringe connected with a stainless steel needle, the diameter of which is 1.0mm;

[0058] 3) Adjust the injection rate of the syringe to 0.2mL / min through the precision propeller, and place a collector made of aluminum at about 15cm in the direction of the stainless steel needle to collect the prepared product, that is, a composite conductive agent with a special structure;

[0059] 4) The obtained composite conductive agent with special structure is extracted with alcohol at 80° C. for 10 minutes to infiltrate, and then the solvent is removed; and then dried to obtain the composite conductive agent with special structure.

[0060] 5) Preparation of the positive pole piece: mix the positive active material lithium cobaltate, the special struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com