Chiral covalent organic framework membrane as well as preparation method and application thereof

A covalent organic framework, chirality technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of high solubility, instability, lack of pore structure, etc., and achieve low cost and excellent acid resistance. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The β-CD COF mixed matrix membrane was first prepared by the following steps, and then the membrane performance was evaluated.

[0048] Synthesis of β-CD COF:

[0049] Hepta(6-amino-6-deoxy)-β-cyclodextrin (20 mmol L -1 ) and terephthalaldehyde (50 mmol L -1 ) was dissolved in a solvent (ethanol-water 50:50 (v / v)), and glacial acetic acid (180 mmol L -1 ) as a catalyst. After ultrasonic mixing, nitrogen gas was flushed for 10 min to remove oxygen in the reaction solution, and the reaction solution was allowed to stand at room temperature for 48 h. After the reaction, the product was collected by centrifugation and washed three times with ethanol and water. Finally, the product was dried in a vacuum oven at 80 °C for 12 h, and the β-CD COF powder was obtained after grinding.

[0050] Preparation of β-CD COF mixed matrix membrane:

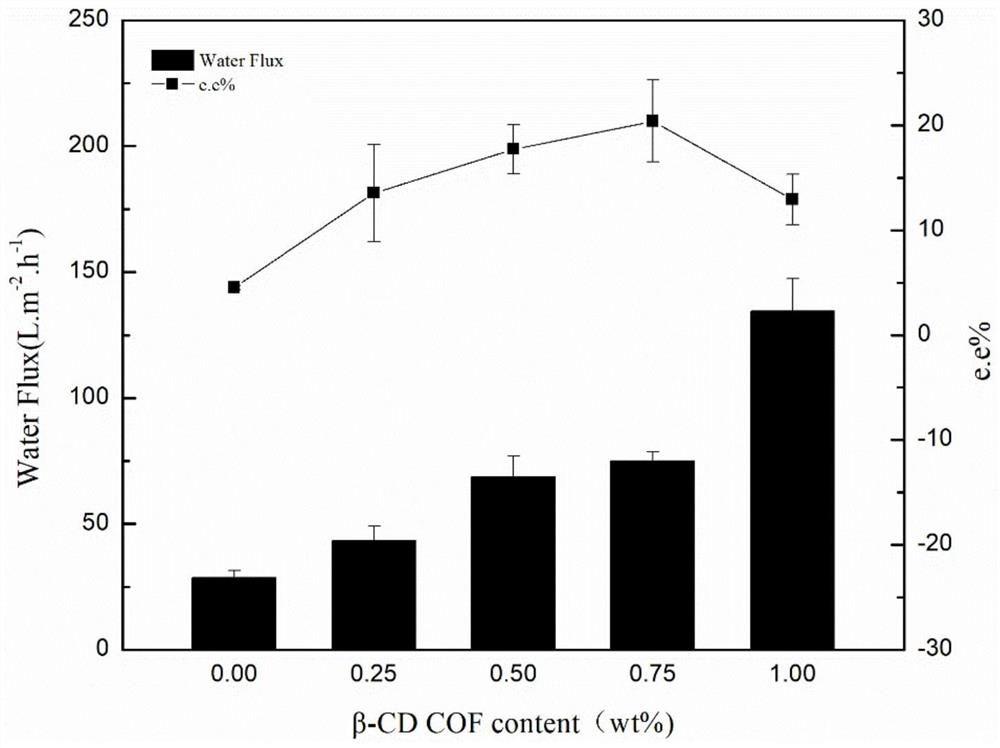

[0051] The cellulose acetate was vacuum-dried at 80°C for 6 h to remove moisture. Weigh 0, 5, 10, 15, and 20 mg of β-CDCOF (the conten...

Embodiment 2

[0057] Change the weighed amount of β-CD COF in Example 1 to 0, 15 mg (the content in the entire casting solution is 0.00, 0.75wt%), the amount of DMF added is changed to 1.600, 1.585 g, and the rest are the same as in the example 1.

[0058] The chemical structure and morphology of the β-CD COF mixed matrix membrane prepared in this example were characterized.

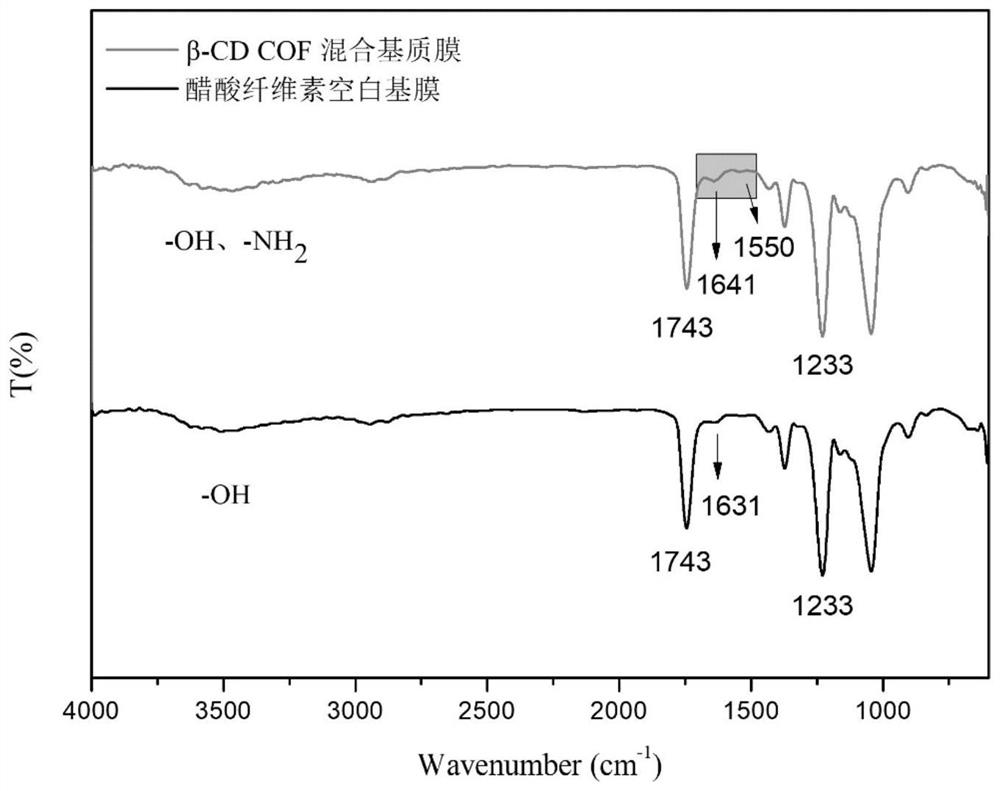

[0059] The chemical structures of the cellulose acetate blank base membrane without β-CD COF and the β-CD COF mixed matrix membrane were observed by ATR-FTIR. Such as figure 2 As shown, compared with the cellulose acetate blank base film without β-CD COF, 1641 and 1550 cm -1 Two new peaks are typical characteristic peaks of amide bonds. The chemical structure of β-CD COF contains amide bonds, which indicates that the mixed matrix membrane of β-CD COF was successfully prepared.

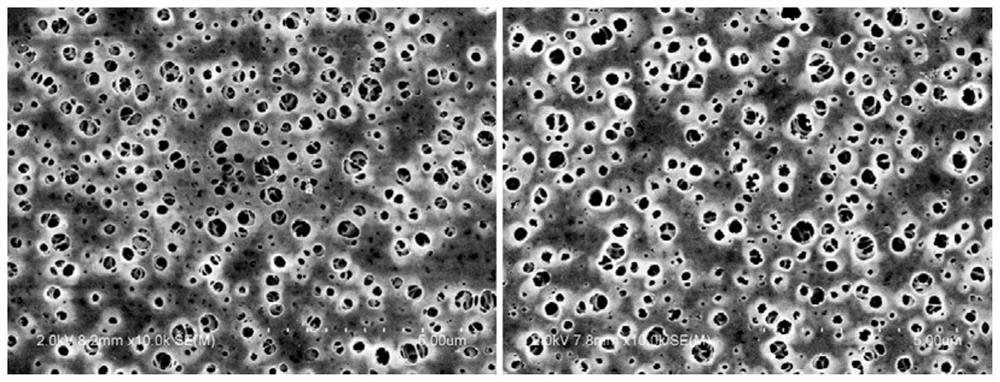

[0060] The cellulose acetate blank base film and β-CD COF mixed matrix film were observed by SEM. image 3 The two electron micrographs...

Embodiment 3

[0064] The weighed amount of β-CD COF in Example 1 was changed to 15 mg (the content in the entire casting solution was 0.75 wt%), the amount of DMF added was changed to 1.585 g, and the rest were the same as in Example 1.

[0065] The pH tolerance range of the β-CD COF mixed matrix membrane prepared in this example was evaluated.

[0066] Select 10mM phosphate buffer with pH values of 1, 3, 5, 9, 11, and 13 as the hydrolysis solution, put the prepared β-CD COF mixed matrix membrane into the above buffer, and at the same time, conduct a blank control group, and put The experimental group and the blank group were placed in a constant temperature shaker at 125 r / min for 12 h at the same time. Then, the total organic carbon (TOC) of the experimental group and the blank group were measured respectively, and the hydrolysis of the membrane at different pH values was judged by comparing the TOC values of the experimental group and the blank group, such as Figure 5 It can be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com