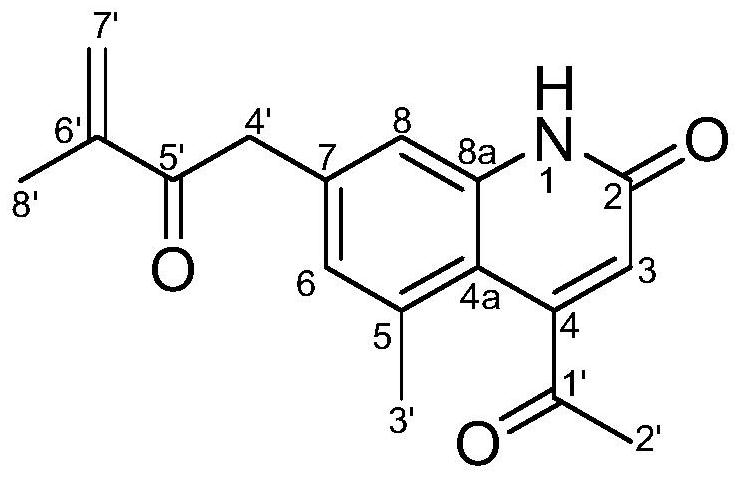

Tobacco black shank-resisting active compound in Thalictrum finetii Boivin as well as preparation method and application of tobacco black shank-resisting active compound

A technology of tobacco black shank and compound, which is applied in the field of phytochemistry, can solve the problems of undiscovered active substances, etc., and achieve the effects of good anti-black shank activity, low cost, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

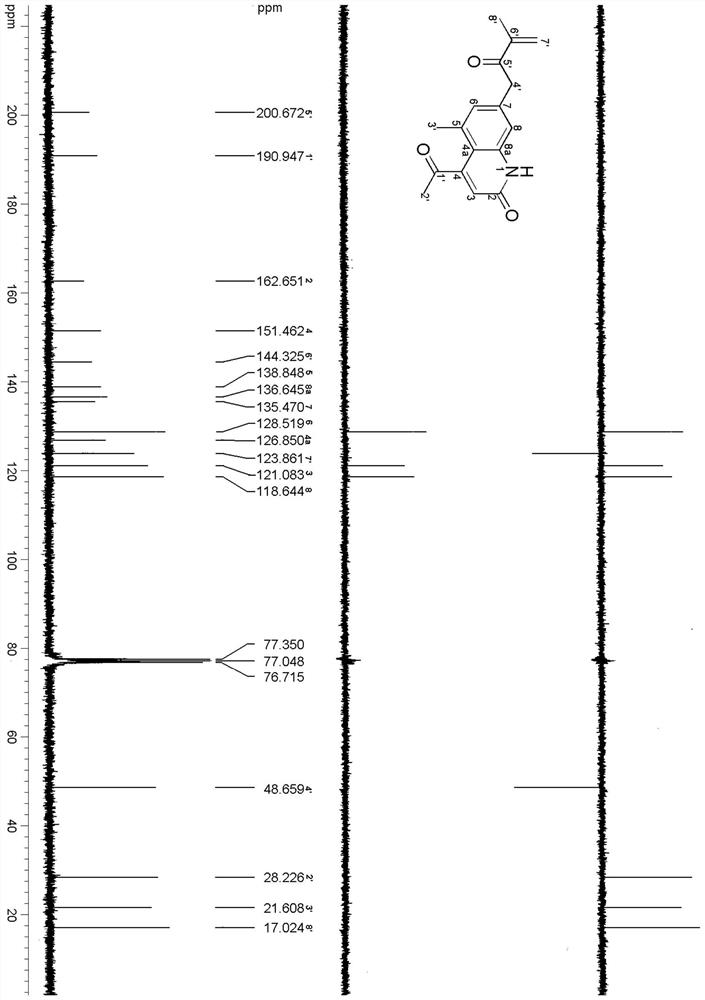

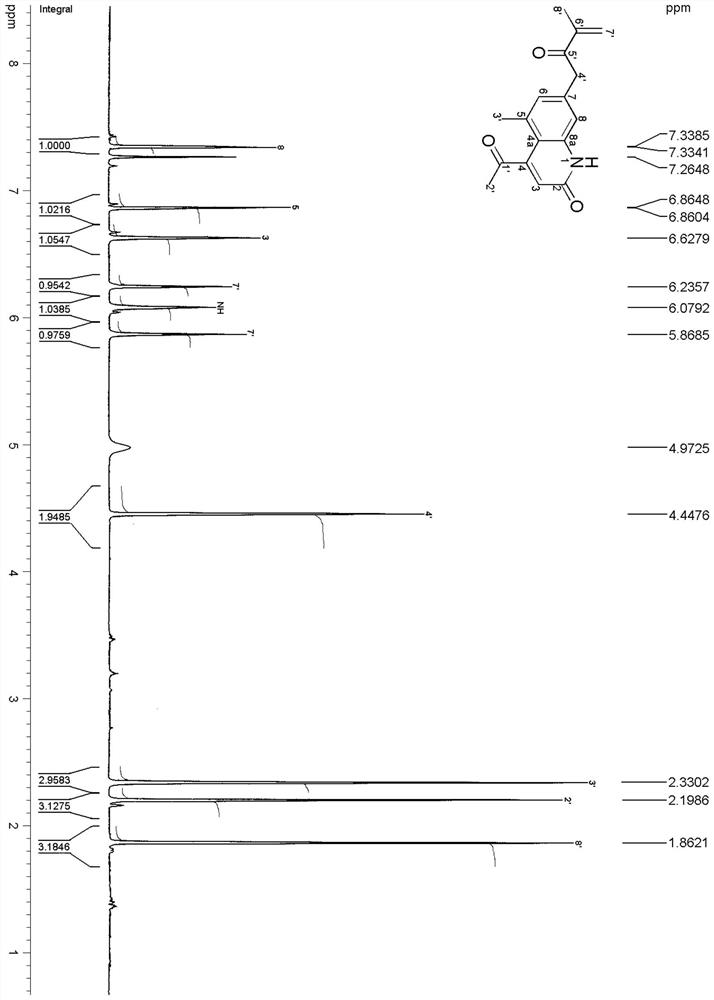

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides the preparation method of described anti-tobacco black shank active compound, specifically comprises the following steps:

[0027] (1) Extraction: dry and pulverize the whole plant of Pinegrass tangensis, take the first solvent for extraction, concentrate, take the second solvent for extraction, the aqueous phase is saturated with sodium carbonate, then extract with the second solvent, combine and concentrate to obtain the extract paste;

[0028] (2) dissolving the extract in a third solvent, separating it through a silica gel column, and eluting with a gradient of chloroform: acetone, and collecting the eluted components with a volume ratio of chloroform: acetone of 9:1;

[0029] (3) The eluted fraction obtained in step 2 was separated by HPLC chromatography to obtain the crude product of the target compound, and finally the crude product of the target compound was purified with a Sephadex column to obtain the pure product of the tar...

Embodiment 1

[0044]The sample of Sichuan-Yunnan Tangsong grass in this example comes from Heqing County, Dali, Yunnan. The whole plant of Pinegrass tangensis from Sichuan and Yunnan was sun-dried and crushed to about 40 mesh. Weigh 3.0 kg of the pulverized sample, place it in a 20 L glass reaction kettle, add 6 L of 95% ethanol aqueous solution, reflux for 50 min, and filter out the extract; add 6 L of 95% ethanol aqueous solution to the residue again, Reflux for extraction for 50 min, and filter the extract. The two extracts were combined and concentrated to a small volume, then diluted with 6 L of 3% tartaric acid solution, and extracted twice with 6 L of ethyl acetate. After the extraction, the aqueous phase was saturated with sodium carbonate, extracted twice with 6 L of ethyl acetate, and the extracted ethyl acetate phases were combined and concentrated under reduced pressure to obtain 48.5 g of alkaloid part extract. The extract was mixed with 60g (80-100 mesh) crude silica gel, dr...

Embodiment 2

[0051] The samples of Pinegrass tangensis in Sichuan and Yunnan came from Binchuan County, Dali, Yunnan. Take the whole plant of Sichuan-Yunnan Tangsong grass, dry it, and crush it to about 40 mesh. Weigh 3.6 kg of the pulverized sample, place it in a 20 L glass reaction kettle, add 8 L of 95% ethanol aqueous solution, reflux for extraction for 40 min, and filter out the extract; add 8 L of 95% ethanol aqueous solution to the residue again , refluxed for 40 min, and filtered off the extract. The two extracts were combined and concentrated to a small volume, then diluted with 8 L of 3% tartaric acid solution, and extracted twice with 8 L of ethyl acetate. After the extraction, the aqueous phase was saturated with sodium carbonate, extracted twice again with 8 L of ethyl acetate, and the extracted ethyl acetate phases were combined and concentrated under reduced pressure to obtain 53.6 g of alkaloid part extract. The extract was mixed with 80g (80-100 mesh) crude silica gel, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com