Oligomeric organosilicon anti-ultraviolet epoxy resin LED packaging adhesive

A technology of LED encapsulation and epoxy resin, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problem of UV instability and achieve good effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides an oligomeric organic silicon anti-ultraviolet epoxy resin LED encapsulation adhesive, including A component and B component, A component and B component are mixed at a ratio of 1:1 for LED encapsulation;

[0026] A component includes epoxy silicone oligomer, alicyclic epoxy resin, reactive diluent, crosslinking agent, transparent blue-violet dye paste and defoamer, wherein the mass fraction of epoxy silicone oligomer 50% to 55%, the mass fraction of cycloaliphatic epoxy resin is 40% to 50%, the mass fraction of reactive diluent is 1% to 4%, the mass fraction of crosslinking agent is 0.5% to 1.5%, transparent The mass fraction of the blue-violet dye paste is 0.2% to 0.8%, and the mass fraction of the defoamer is 0.2% to 0.5%;

[0027] In this embodiment, the cycloaliphatic epoxy resin is 3,4-epoxycyclohexylmethyl 3', 4'-epoxycyclohexyl carboxylate, bis((3,4-epoxycyclohexyl) methyl base) adipate and 4,5-epoxycyclohexane-1,2-dicarboxylate diglyci...

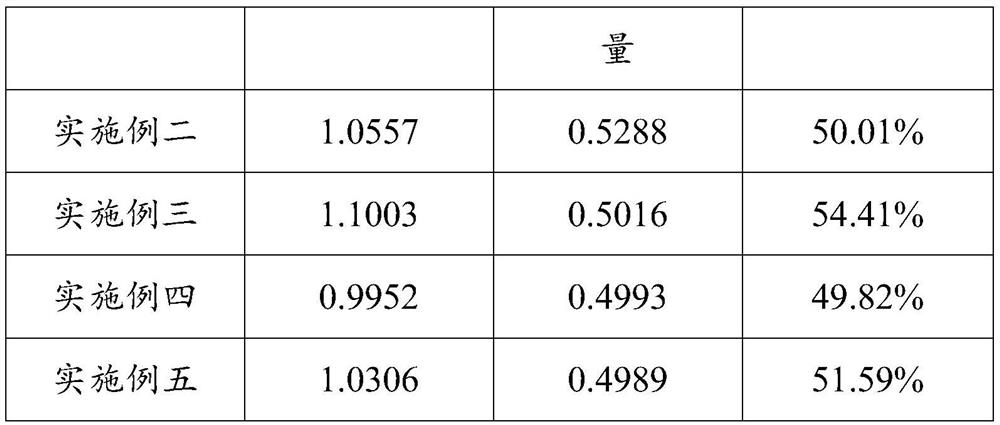

Embodiment 2

[0035] This embodiment provides an oligomeric silicone anti-ultraviolet epoxy resin LED encapsulant, including A component and B component;

[0036] The preparation method process of A component is as follows:

[0037] First prepare the epoxy silicone oligomer in component A, and prepare it according to the following steps: (1) 3-(2,3 glycidoxy)propyltrimethoxysilane and dimethoxysilane with a molar ratio of 1:1 Methyldimethoxysilane is added in dehydrated alcohol, and the volume ratio of the amount of substance of 3-(2,3 glycidoxy) propyltrimethoxysilane and dehydrated alcohol is 1mol:800mL; (2) Then add distilled water to the solution obtained in the previous steps, react at a temperature of 60°C for 10 hours, and finally use a rotary evaporator to remove the solvent to obtain an epoxy silicone oligomer, the molar ratio of distilled water to dimethyldimethoxysilane 1:0.9;

[0038] Then the mass fraction is 50% epoxy silicone oligomer, 45% 3,4-epoxycyclohexylmethyl 3',4'-ep...

Embodiment 3

[0042] This embodiment provides an oligomeric silicone anti-ultraviolet epoxy resin LED encapsulant, including A component and B component;

[0043] The preparation method process of A component is as follows:

[0044] First prepare the epoxy silicone oligomer in component A, and prepare it according to the following steps: (1) 3-(2,3 glycidoxy)propyltriethoxysilane with a molar ratio of 1:1 Methylphenyldimethoxysilane is added to absolute ethanol, and the volume ratio of the amount of 3-(2,3 glycidoxy) propyltriethoxysilane to absolute ethanol is 1mol:700mL; (2) Then add distilled water to the solution obtained in the previous step, react at a temperature of 70°C for 9 hours, and finally use a rotary evaporator to remove the solvent to obtain an epoxy silicone oligomer, distilled water and methylphenyldimethoxy The molar ratio of silane is 1:1;

[0045] Then the mass fraction of 50% epoxy silicone oligomer, 45% 4,5-epoxycyclohexane-1, 2-dicarboxylic acid diglycidyl ester, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com