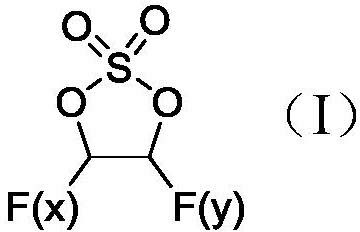

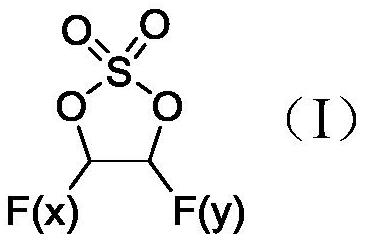

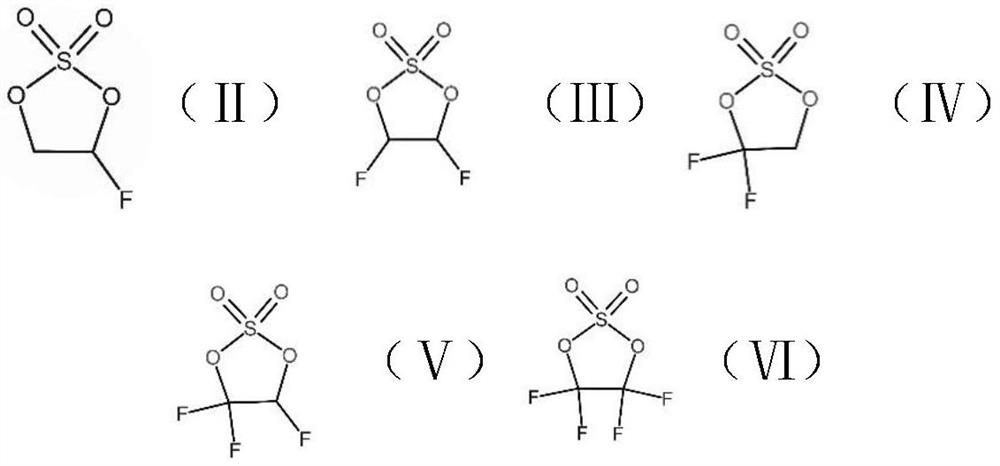

Preparation method of fluoroethylene sulfate

The technology of vinyl fluorosulfate and vinyl monofluorosulfate is applied in the preparation field of preparing vinyl fluorosulfate by an electrolytic fluorination method, and can solve the problems of complicated reaction and operation, high toxicity of fluorination reagents and resource utilization rate. It can achieve the effect of environmental friendliness, avoiding the production of intermediate products, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Mix 0.8 mol of vinyl sulfate and 35 mol of anhydrous hydrogen fluoride (moisture content 20000ppm) to obtain anhydrous hydrogen fluoride solution of vinyl sulfate, put it into a 1L electrolytic cell, control the voltage to 5V and the current to 45A at room temperature, and perform electrolytic dehydration . After removing water for 8 hours, electrolytic fluorination was carried out under normal pressure. The reaction tank temperature was controlled at 0°C, the electrolysis voltage was 5.5V, the electrolysis current was 80A, and the reaction time was 10h. After the reaction is completed, the reaction solution is discharged from the bottom of the electrolytic cell, and an acid scavenging agent calcium oxide is added to obtain a crude product of vinyl fluorosulfate. After rectification, a vinyl fluorosulfate product with a purity higher than 99.5% is obtained. After calculation, the conversion rate of vinyl sulfate is 82.43%, and the selectivity of vinyl fluorosulfate is ...

Embodiment 2

[0031] Mix 0.6mol vinyl sulfate and 35mol anhydrous hydrogen fluoride (moisture content 35000ppm) to obtain anhydrous hydrogen fluoride solution of vinyl sulfate, put it into a 1L electrolytic cell, control the voltage to 7V and current to 50A at room temperature, and perform electrolytic dehydration . After removing water for 10 hours, electrolytic fluorination was carried out under normal pressure. The reaction tank temperature was controlled at 40°C, the electrolysis voltage was 7.5V, the electrolysis current was 75A, and the reaction time was 11h. After the reaction is completed, the reaction solution is discharged from the bottom of the electrolytic cell, and the acid scavenger aluminum oxide is added to obtain the crude product of vinyl fluorosulfate. After rectification, the product of vinyl fluorosulfate with a purity higher than 99.5% is obtained. After calculation, the conversion rate of vinyl sulfate is 81.99%, and the selectivity of vinyl fluorosulfate is 93.46%. ...

Embodiment 3

[0033] Mix 2 mol of vinyl sulfate and 25 mol of anhydrous hydrogen fluoride (moisture content 40000ppm) to obtain anhydrous hydrogen fluoride solution of vinyl sulfate, put it into a 1L electrolytic cell, control the voltage to 4.5V and the current to 35A at room temperature, and perform electrolytic dehydration . After removing water for 11 hours, electrolytic fluorination was carried out under normal pressure. The reaction tank temperature was controlled at 25°C, the electrolysis voltage was 5V, the electrolysis current was 120A, and the reaction time was 7h. After the reaction is completed, the reaction solution is discharged from the bottom of the electrolytic cell, and the acid scavenger aluminum oxide is added to obtain the crude product of vinyl fluorosulfate. After rectification, the product of vinyl fluorosulfate with a purity higher than 99.5% is obtained. According to calculation, the conversion rate of vinyl sulfate is 79.71%, and the selectivity of vinyl fluorosu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com