Elastic strain sensor and preparation method thereof

A strain sensor, elastic strain technology, used in flexible wearable sensors, human-computer interaction, wearable devices, medical rehabilitation training fields, it can solve the problem that the stretching range is only 15%, the liquid metal is easy to leak, and the stretching range is small, etc. problems, to achieve the effect of improving sensitivity and sensor life, good electrical and mechanical properties, excellent tensile properties and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

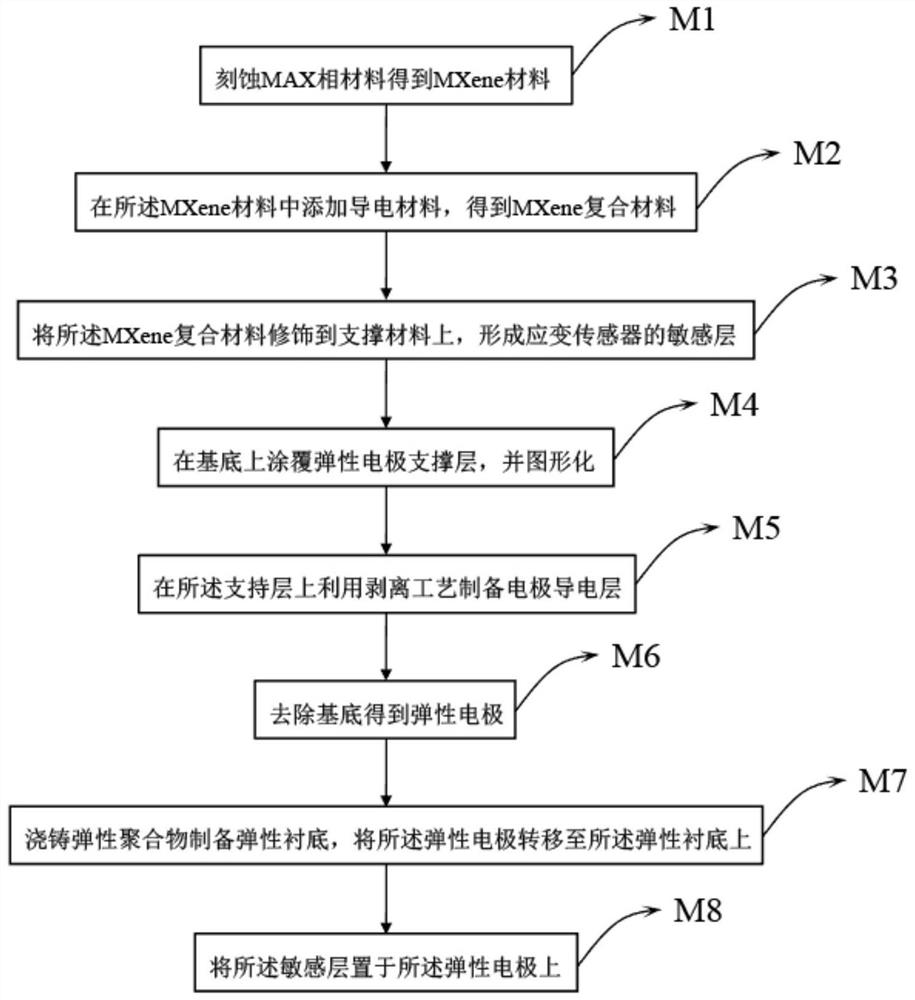

[0044] According to a method for preparing an elastic strain sensor provided by the present invention, comprising:

[0045] Step M1: Etching the MAX phase material to obtain the MXene material;

[0046] Step M2: adding a conductive material to the MXene material to obtain an MXene composite material;

[0047] Step M3: modifying the MXene composite material on the support material to form a sensitive layer of the strain sensor;

[0048] Step M4: Coating an elastic electrode support layer on the substrate and patterning it;

[0049] Step M5: preparing an electrode conductive layer on the elastic electrode support layer by using a peeling process;

[0050] Step M6: removing the substrate to obtain an elastic electrode;

[0051] Step M7: casting an elastic polymer to prepare an elastic substrate, and transferring the elastic electrodes to the elastic substrate;

[0052] Step M8: placing the sensitive layer of the strain sensor on the elastic electrode to obtain an elastic stra...

Embodiment 2

[0067] Embodiment 2 is a modification of embodiment 1

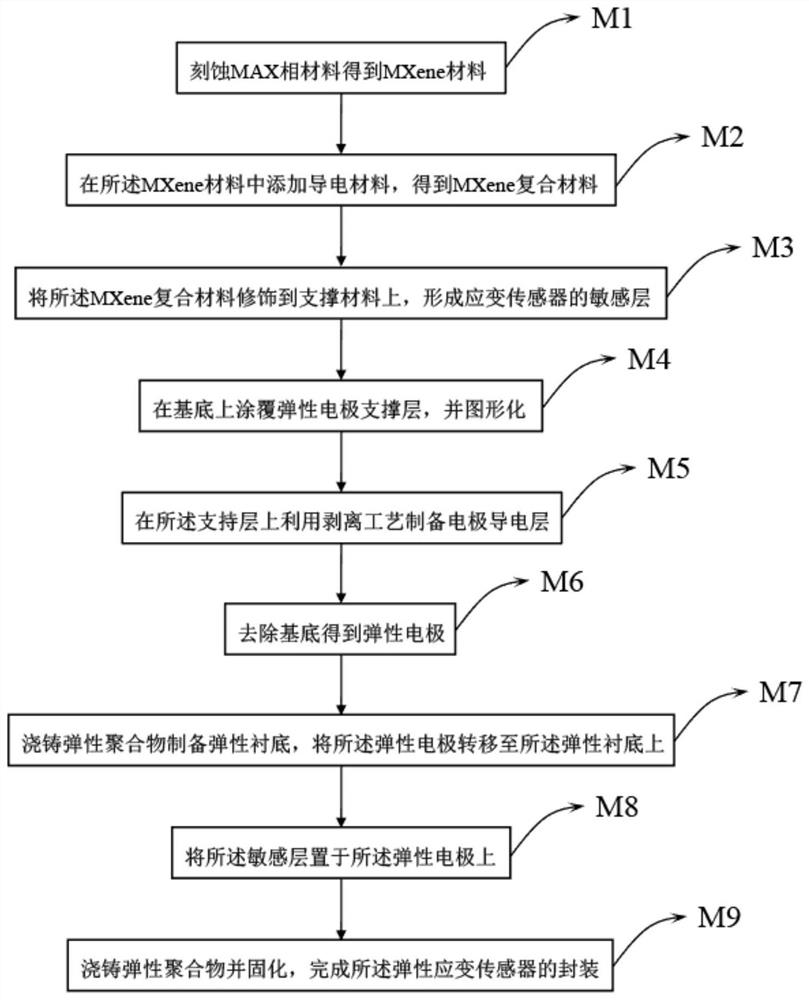

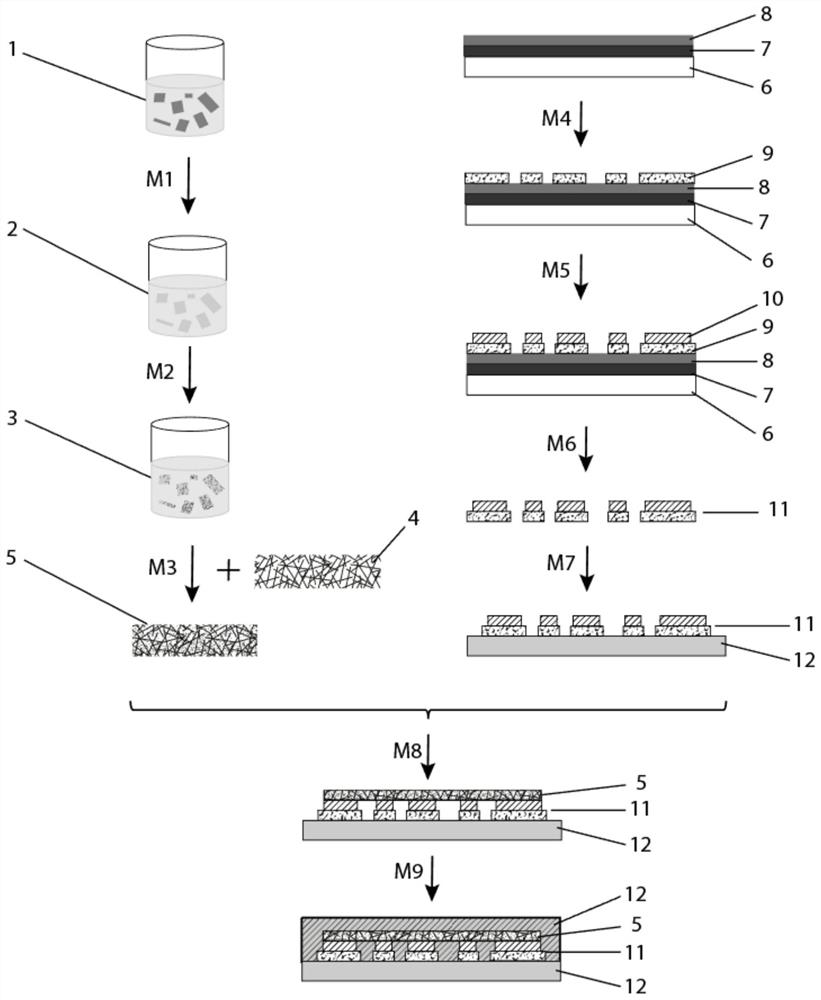

[0068] According to an embodiment of the present invention, a method for preparing an elastic strain sensor is provided, see figure 1 , including the following preparation steps:

[0069] M1. Etching MAX phase material 1 to obtain MXene material 2;

[0070] M2. add conductive material in described MXene material 2, obtain MXene composite material 3;

[0071] M3. modify the MXene composite material 3 on the support material 4 to form the sensitive layer 5 of the strain sensor;

[0072] M4. coating elastic electrode support layer 9 on substrate 8, and patterning;

[0073] M5. Utilize stripping process to prepare electrode conductive layer 10 on described supporting layer 9;

[0074] M6. remove the substrate 8 to obtain the elastic electrode 11;

[0075] M7. Cast elastic polymer 12 to prepare elastic substrate, and transfer the elastic electrode 11 to the elastic substrate;

[0076] M8. Place the sensitive layer 5 on t...

Embodiment 3

[0093] Embodiment 3 is a modification of embodiment 1 and / or 2

[0094] The MXene composite material 3 is a composite material of MXene and silver nanowires; the support material 4 is cotton with a thickness of 0.3 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com