Non-contact flexible transparent sensor and preparation method thereof

A non-contact, sensor technology, applied in the field of flexible sensors, can solve the problems of difficult monitoring, weak output induction signal, and difficult integration of external equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

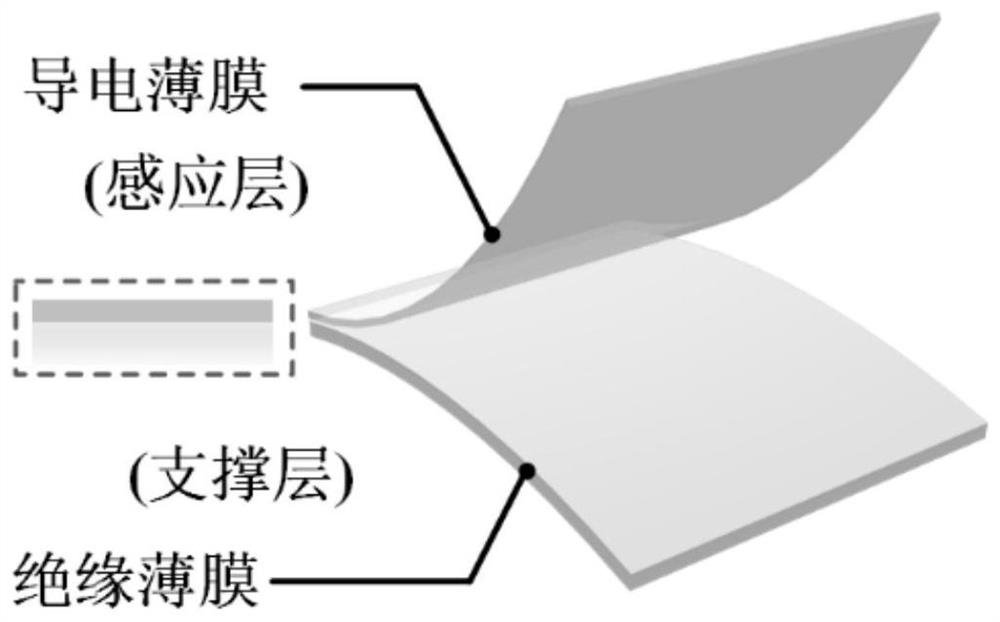

Method used

Image

Examples

Embodiment 1

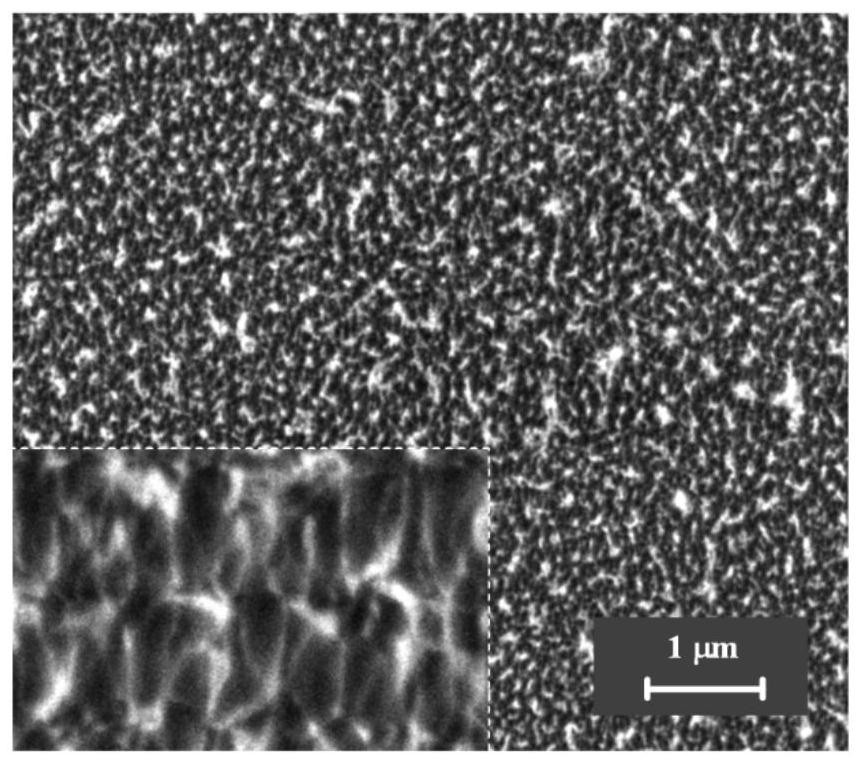

[0049] 1) Place the PET substrate in an inductively coupled plasma etching chamber, introduce oxygen into the vacuumed chamber, and then apply a power of 150W to etch for 150s to realize the preliminary nanostructure design of the substrate;

[0050] 2) Transfer the rough surface to the coating equipment. After vacuuming the cavity, deposit the conductive transparent material ITO on the surface of the sample to form an induction layer. The type and thickness of the deposited film can be controlled by controlling the type of target and the deposition time;

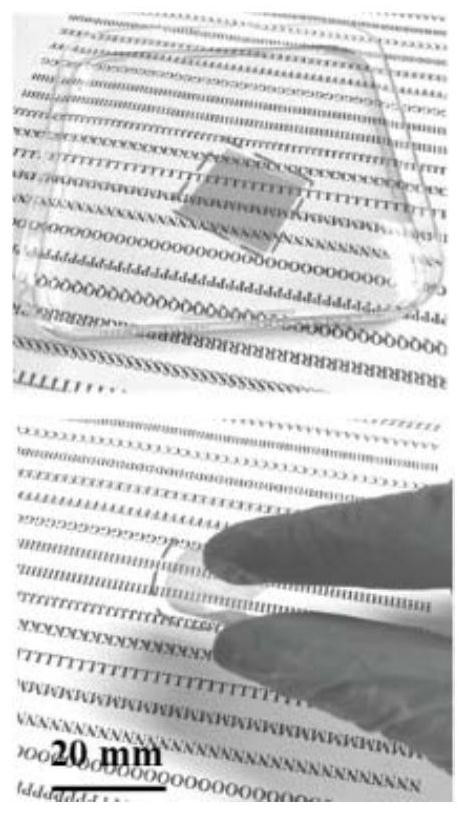

[0051] 3) Prepare signal output electrodes at the four ends of the sensor for outputting horizontal and vertical signals;

[0052] 4) By collecting and analyzing the four-terminal output signals, the corresponding operation commands are realized.

Embodiment 2

[0054] 1) Place the PDMS substrate in an inductively coupled plasma etching chamber, introduce oxygen into the vacuumed chamber, and then apply a power of 100W to etch for 200s to realize the preliminary nanostructure design of the substrate;

[0055] 2) Transfer the rough surface to the coating equipment. After vacuuming the cavity, deposit the conductive transparent material ITO on the surface of the sample to form an induction layer. The type and thickness of the deposited film can be controlled by controlling the type of target and the deposition time;

[0056] 3) Prepare signal output electrodes at the four ends of the sensor for outputting horizontal and vertical signals;

[0057] 4) By collecting and analyzing the four-terminal output signals, the corresponding operation commands are realized.

Embodiment 3

[0059] 1) The glass substrate is placed in the reactive ion etching chamber, and the SF 6 Pass it into the vacuumed cavity, and then apply a power of 120W to etch for 150s to realize the preliminary structural design of the substrate;

[0060] 2) Transfer the rough surface to the coating equipment. After vacuuming the cavity, deposit the conductive transparent material ITO on the surface of the sample to form an induction layer. The type and thickness of the deposited film can be controlled by controlling the type of target and the deposition time;

[0061] 3) Prepare signal output electrodes at the four ends of the sensor for outputting horizontal and vertical signals;

[0062] 4) By collecting and analyzing the four-terminal output signals, the corresponding operation commands are realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com